The RZT7-03ZUS-KR0 is a sensor specifically designed for T-slot pneumatic cylinders.It features an M8 sensor interface,an integrated reed switch,and supports magnetic switch functionality,enabling high-precision position detection and control.Thanks to its compact design,high sensitivity,and reliable performance,this sensor excels in various complex operating conditions and is an essential detection component in industrial automation.

Product Specifications

Housing Dimensions:29.5 mm in length,with a compact design suitable for installation in tight spaces.

Output Type:Reed switch,normally open contact,supporting 2-wire AC/DC connection.

Electrical Parameters:Supply voltage ranging from 5 V AC/DC to 30 V AC/DC,maximum continuous current of 100 mA,and switching power≤6 W.

Protection Rating:IP65/IP67,suitable for environments with high humidity and dust.

Response Sensitivity:A typical value of 3 mT with a reproducibility of≤0.1 mT,ensuring high-precision detection.

Operating Temperature:-30°C to+80°C,adaptable to a wide range of industrial environments.

Connection Method:M8 interface with a knurled nut,3-pin configuration,suitable for drag chains,and a cable length of 0.5 meters.

Product Features

High-Precision Detection:Utilizing reed switch technology combined with magnetic switch functionality,it achieves high-precision position detection,suitable for industrial applications with extremely high accuracy requirements.

Compact Design:With a housing length of 29.5 mm,it can be easily installed in tight spaces,especially for the detection needs of T-slot pneumatic cylinders.

Compatibility with Various Cylinders:Supports multiple types of cylinders,including cylindrical,rod,and dovetail cylinders,offering extensive applicability.

High Reliability:Features impact and vibration resistance(30 g,11 ms)and complies with the electromagnetic compatibility standard EN 60947-5-2,ensuring stable operation in harsh environments.

Status Indication:Equipped with an LED indicator light that displays the sensor's operating status in real-time,facilitating troubleshooting and maintenance.

Applications

Cylinder Position Detection:In automated production lines,it detects the position of the cylinder piston to achieve precise automated control.

Robotic Arm Positioning:In robotic and robotic arm applications,it enables precise motion control by detecting the position of the cylinder.

Conveyor Belt Systems:Used to detect the position of materials on conveyor belts to ensure accurate material transportation and processing.

Packaging Equipment:In packaging machinery,it detects the position of packaging materials to enable automated packaging processes.

Automotive Manufacturing:In automotive production lines,it detects the position of cylinders and mechanical components to improve production efficiency and product quality.

Installation and Wiring

Installation Location:Install in an environment free of dust,corrosive gases,and strong electromagnetic interference,ensuring the sensor's housing is tightly attached to the cylinder.

Wiring Requirements:Follow the product manual strictly for wiring,ensuring correct connections of power and signal lines.When using the M8 interface,pay attention to the plug's secure fit and sealing.

Grounding Protection:Ensure proper grounding of the equipment in compliance with electrical safety standards to minimize electromagnetic interference.

Parameter Settings:

Sensitivity Adjustment:Optimize the sensor's detection performance by adjusting the sensitivity parameter according to specific application requirements.

Output Function:Supports normally open contact output,configurable according to control needs.

Maintenance and Inspection

Regular Checks:Inspect the sensor's appearance for damage and ensure the housing is securely attached to the cylinder.

Cleaning and Maintenance:Regularly clean the sensor's surface of dust and oil to prevent detection accuracy issues.

Troubleshooting:When a fault occurs,use the LED indicator light to identify the fault type and troubleshoot according to the manual.

Precautions

Environmental Conditions:Avoid using the sensor in high-temperature,high-humidity,or strong electromagnetic interference environments to prevent performance degradation and reduced lifespan.

Power Supply Requirements:Ensure stable power supply voltage to avoid damage to the sensor from voltage fluctuations.

Safety Operations:Avoid contact with live parts during equipment operation to ensure operator safety.Always disconnect power before maintenance.

Materials and Manufacturing Process

The RZT7-03ZUS-KR0 sensor is made from high-quality materials and advanced manufacturing processes to ensure reliability and durability in harsh environments.The housing is made of plastic Grilamid LVX-65H,which offers excellent mechanical properties and chemical resistance,effectively protecting the sensor from dust,oil,and common industrial chemicals.The sensor's cable is made of PUR material,known for its flexibility and wear resistance,making it suitable for dynamic applications such as drag chains.The manufacturing process involves precision mechanical machining and strict assembly procedures to ensure precise component fit,guaranteeing the high sensitivity and accuracy of the reed switch and magnetic switch.

Additional Features

The RZT7-03ZUS-KR0 sensor not only features basic magnetic switch functionality but also includes several practical additional features.For example,the built-in switch status LED indicator light displays the sensor's operating status in real-time,allowing users to quickly determine whether the device is functioning properly.The sensor also offers impact and vibration resistance(30 g,11 ms)and complies with the electromagnetic compatibility standard EN 60947-5-2,reducing the impact of electromagnetic interference on sensor performance.These additional features make the RZT7-03ZUS-KR0 sensor stand out in complex industrial applications,providing users with a reliable detection solution.

Product Advantages

The RZT7-03ZUS-KR0 sensor has several significant advantages that set it apart from similar products.First,its compact housing design(only 29.5 mm in length)allows for easy installation in tight spaces,making it ideal for compact devices such as T-slot pneumatic cylinders.Second,the sensor's sensitivity is typically 3 mT with a reproducibility of 0.1 mT,enabling high-precision position detection.Additionally,the M8 interface supports 2-wire AC/DC connection,simplifying installation and wiring and significantly reducing user installation costs.Finally,the housing's protection rating of IP65/IP67 effectively prevents dust and moisture ingress,ensuring long-term stable operation in humid and dusty environments.

After-Sales Service

To ensure a smooth experience with the RZT7-03ZUS-KR0 sensor,the manufacturer offers a comprehensive range of after-sales services.Users can access detailed product data sheets,installation guides,and troubleshooting manuals on the manufacturer's official website(e.g.,SICK website).Additionally,the manufacturer provides a professional technical support team available to assist users with any issues they encounter.For replacement parts such as mounting brackets or cables,the manufacturer offers a wide range of recommended accessories that users can select based on their needs.These comprehensive after-sales services provide users with full support,ensuring worry-free use of the RZT7-03ZUS-KR0 sensor.

Frequently Asked Questions(FAQ)

1.How to Ensure the Magnetic Switch Function of the RZT7-03ZUS-KR0 Sensor Works Properly?

Importance of Magnetic Switch:The magnetic switch is a core feature of the RZT7-03ZUS-KR0 sensor,enabling high-precision position detection by sensing magnetic field changes.Its proper operation is crucial for precise control in automation equipment.In industrial applications,the sensitivity and response speed of the magnetic switch directly affect the efficiency and reliability of the equipment.

Installation Considerations:When installing the sensor,ensure the distance between it and the magnetic element complies with the technical specifications.Avoid placing sources of magnetic interference near the sensor to maintain its sensitivity and accuracy.Additionally,check that the magnetic element's field strength falls within the sensor's response range to prevent false triggering or missed detections.

Regular Calibration:Periodically check the sensitivity and response speed of the magnetic switch,and calibrate it if necessary to ensure long-term stable operation.If you notice a decrease in detection accuracy or response delay,adjust or replace the magnetic element promptly to maintain normal equipment operation.

2.What is the Lifespan of the Reed Switch in the RZT7-03ZUS-KR0 Sensor?

Durability of Reed Switch:The reed switch is a vital component of the RZT7-03ZUS-KR0 sensor,designed for a lifespan of up to 10 million switch operations.This high-life design allows it to withstand frequent operations in industrial environments,reducing replacement frequency and maintenance costs.

Factors Affecting Lifespan:The lifespan of the reed switch is influenced by various factors,including ambient temperature,humidity,electromagnetic interference,and operating frequency.In high-temperature,high-humidity,or strong electromagnetic interference environments,the lifespan may be shortened.Therefore,ensuring the sensor operates under suitable environmental conditions is key to extending its lifespan.

Maintenance Recommendations:Regularly inspect the reed switch's operating condition,looking for signs of poor contact or sluggish response.If issues arise,replace the reed switch or the entire sensor promptly to prevent equipment downtime due to switch failure.

3.How to Choose the Right M8 Sensor Interface?

Importance of Interface Type:The RZT7-03ZUS-KR0 sensor uses an M8 interface,which is widely used in industrial automation due to its compactness and high reliability.The M8 interface supports various connection methods,including cable and connector connections,to meet different installation requirements.

Choosing the Right Cable:When selecting an M8 interface cable,consider the length,material,and shielding performance of the cable.Longer cables may introduce additional resistance and electromagnetic interference,so it is recommended to choose high-quality shielded cables and ensure proper grounding of the shielding layer to minimize signal interference.

Installation Considerations:When installing the M8 interface,ensure a secure connection to avoid signal loss or poor contact due to loosening.Also,pay attention to the seal of the interface to prevent dust and moisture from entering and affecting the service life of the interface.

4.How to Avoid Electromagnetic Interference with the RZT7-03ZUS-KR0 Sensor?

Role of Built-in Filters:The RZT7-03ZUS-KR0 sensor is equipped with an EMC filter and complies with relevant electromagnetic compatibility standards,effectively suppressing electromagnetic interference.This design allows the sensor to operate stably in complex electromagnetic environments,reducing the probability of false triggering.

Wiring Considerations:When wiring,avoid placing signal cables close to power cables to minimize electromagnetic interference.Use shielded cables for signal connections and ensure proper grounding of the shielding layer.Additionally,avoid installing the sensor near strong electromagnetic fields,such as large motors or transformers.

Grounding Measures:Proper grounding is crucial for reducing electromagnetic interference.Ensure that the equipment is properly grounded in accordance with national and local electrical safety standards.The grounding resistance should be as low as possible to effectively conduct interference currents and protect the sensor's normal operation.

5.How Fast is the Response Speed of the RZT7-03ZUS-KR0 Sensor?

Advantages of High Response Speed:The RZT7-03ZUS-KR0 sensor has a very fast response speed,capable of detecting changes in the magnetic field and outputting signals in a short time.This high response speed makes it suitable for high-speed automated production lines,ensuring precise control and efficient operation of the equipment.

Factors Affecting Response Speed:The response speed of the sensor is influenced by various factors,including magnetic field strength,ambient temperature,and sensor sensitivity settings.In cases where the magnetic field is weak or the ambient temperature fluctuates significantly,the response speed may be slightly reduced.Therefore,it is recommended to calibrate the sensor before installation to ensure optimal performance in actual applications.

Optimization Tips:To further enhance response speed,optimize the installation position of the sensor and the selection of magnetic elements.Ensure that the magnetic element has sufficient field strength and minimize the distance between the sensor and the magnetic element to improve detection accuracy and response speed.

6.How to Extend the Service Life of the RZT7-03ZUS-KR0 Sensor?

Impact of Environmental Conditions:The service life of the RZT7-03ZUS-KR0 sensor is significantly affected by environmental conditions.Avoid using it in high-temperature,high-humidity,or strong electromagnetic interference environments to extend its lifespan.Additionally,regularly clean the sensor's surface of dust and oil to prevent reduced detection accuracy or poor heat dissipation due to dust accumulation.

Importance of Regular Maintenance:Periodically inspect the sensor's appearance for damage and ensure that the housing is securely attached to the cylinder.Check the M8 interface for loose connections and tighten if necessary.Also,monitor the reed switch's operating condition for signs of poor contact or sluggish response.

Troubleshooting and Repair:When a sensor malfunctions,promptly check the status of the LED indicator and troubleshoot according to the manual's fault diagnosis guide.If the issue persists,consider contacting a professional technician or replacing the sensor to minimize equipment downtime.

7.What Should I Pay Attention to When Installing the RZT7-03ZUS-KR0 Sensor?

Installation Location:Choose an installation location with good ventilation,free of dust and corrosive gases,and avoid high-temperature,high-humidity,or strong electromagnetic interference environments.Ensure that the sensor's housing is tightly attached to the cylinder to improve detection accuracy.

Optimizing Installation Method:The sensor should be installed vertically to facilitate heat dissipation and reduce the impact of vibrations on the equipment.Use appropriate mounting methods to prevent loosening or damage due to vibrations.If the sensor is installed in a drag chain,ensure that the chain's movement does not cause excessive pulling on the sensor.

Power Connection Considerations:When connecting the power supply,ensure that the power cable meets the required specifications and pay attention to the correct phase sequence.Also,ensure proper grounding of the equipment in accordance with electrical safety standards to minimize the risk of electromagnetic interference and equipment damage.

8.How to Choose the Right Magnetic Element for the RZT7-03ZUS-KR0 Sensor?

Types of Magnetic Elements:The RZT7-03ZUS-KR0 sensor supports various types of magnetic elements,including permanent magnets and electromagnets.When selecting a magnetic element,optimize based on the sensor's sensitivity and application scenario.Permanent magnets are suitable for static detection,while electromagnets are better for dynamic detection.

Magnetic Field Strength Requirements:The sensor has a sensitivity of 3 mT with a reproducibility of 0.1 mT.Therefore,the magnetic element's field strength should be at least 3 mT to ensure reliable detection of magnetic field changes.Avoid using magnetic elements with excessively high field strengths to prevent false triggering of the sensor.

Optimizing Installation Position:The magnetic element should be installed within the sensor's detection range and as close to the sensor's sensing surface as possible.Avoid contact between the magnetic element and other metal objects to reduce magnetic field interference.If detecting multiple positions,use multiple magnetic elements and ensure their magnetic fields do not interfere with each other.

9.What is the Protection Rating of the RZT7-03ZUS-KR0 Sensor?

Definition of Protection Rating:The RZT7-03ZUS-KR0 sensor has a protection rating of IP65/IP67,meaning it can effectively prevent dust ingress and withstand low-pressure water jets and short-term water immersion.This high protection rating allows it to operate stably in environments with high humidity and dust.

Importance of Protection Rating:In industrial automation applications,equipment often needs to operate in harsh environments.A high protection rating for sensors effectively prevents dust,moisture,and other contaminants from entering the device,thereby extending its lifespan and improving its reliability.

Maintenance Tips:Despite its high protection rating,regularly inspect the sensor's housing for seal integrity to ensure the protection rating is maintained.If damage or poor sealing is detected,repair or replace the housing promptly to prevent dust and moisture from entering the device.

10.How to Calibrate the Sensitivity of the RZT7-03ZUS-KR0 Sensor?

Importance of Sensitivity Calibration:The sensitivity of the RZT7-03ZUS-KR0 sensor can be optimized through external adjustment.Sensitivity calibration is a key step to ensure the sensor accurately detects magnetic field changes,especially when the magnetic element is replaced or the installation position changes.Proper sensitivity settings can improve detection accuracy and reduce the probability of false or missed triggers,ensuring stable equipment operation.

Calibration Steps:To calibrate the sensitivity,first install the sensor in the detection position and ensure the magnetic element's field strength falls within the sensor's response range.Then,adjust the sensitivity using the adjustment knob on the sensor or an external tool until the sensor reliably detects the magnetic field changes and outputs a signal.It is recommended to perform calibration in an interference-free environment to ensure the accuracy of the calibration results.

Precautions:During calibration,avoid bringing magnetic interference sources close to the sensor to prevent inaccurate calibration results.After calibration,conduct multiple tests to ensure the sensor's stability and reliability in actual applications.If the sensor experiences reduced detection accuracy during use,it may be necessary to recalibrate the sensitivity to restore optimal performance.

FAQ

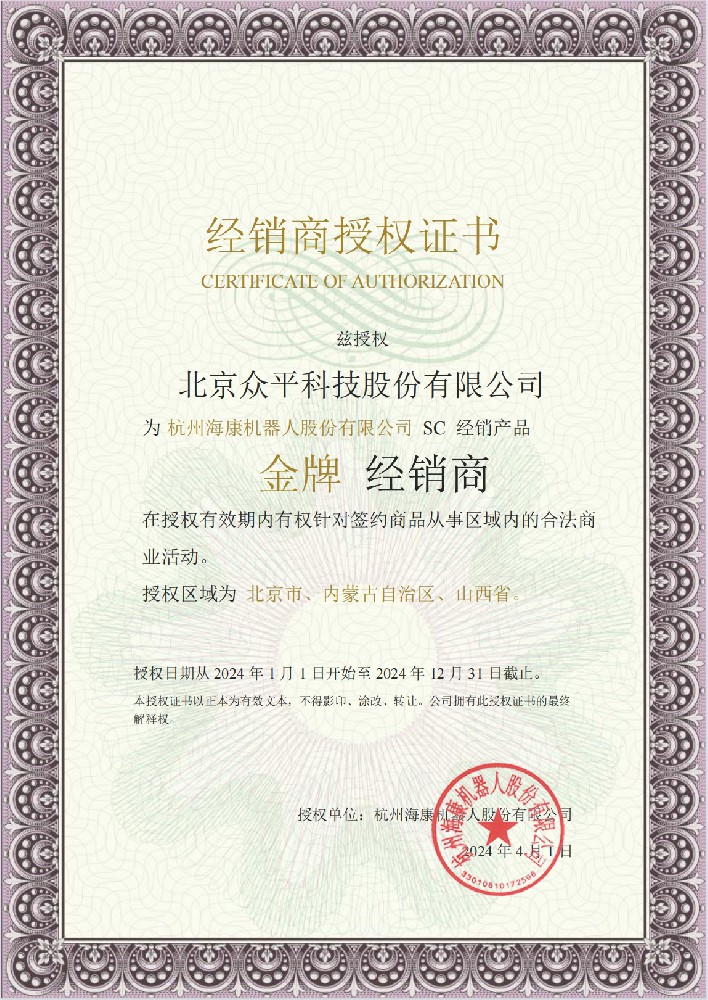

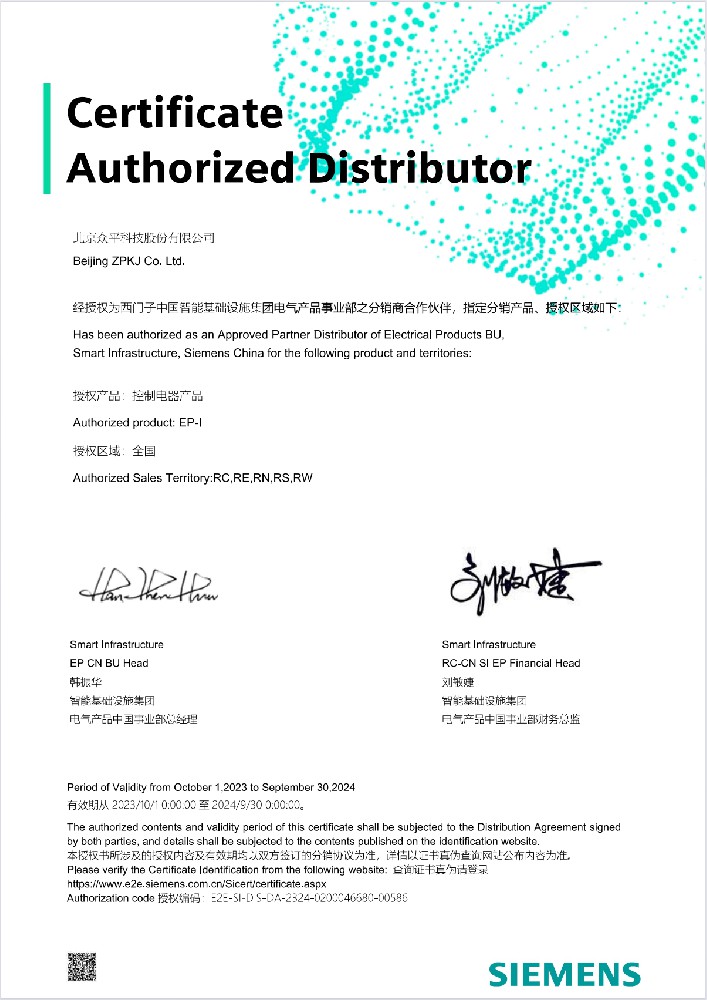

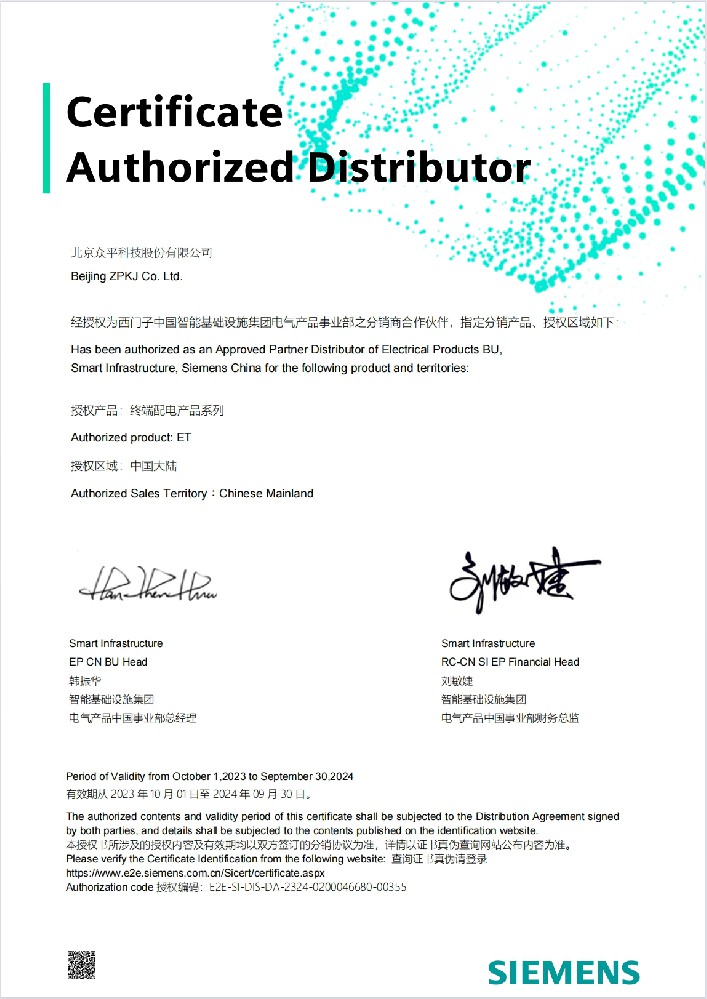

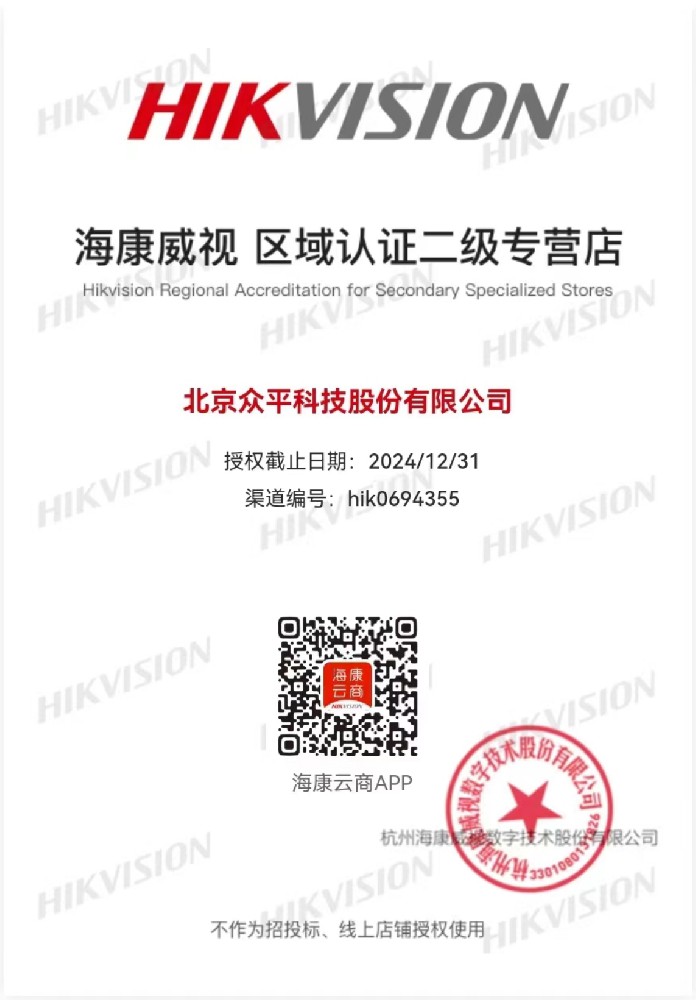

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China