The SICK FX3-MOC Y-CABLE is a specially designed connector cable launched by SICK for their FX3-MOC motion control module.This cable efficiently connects SICK modules with HTL,TTL,or sine/cosine encoders,ensuring stable and reliable signal transmission.With its outstanding performance and flexible connection options,the FX3-MOC Y-CABLE has become an essential component in many industrial automation systems.

Product Specifications

Connection Type:The A end features a Micro D-Sub 15-pin plug,while the B end includes two M12 8-pin sockets.

Cable Length:Various lengths are available depending on the model,such as 0.6 meters,2.4 meters,and 1 meter.

Operating Temperature:For fixed installation,the temperature range is-10°C to+80°C;for movable applications,it is-25°C to+80°C.

Cable Material:PVC conductors with cross-sectional areas of AWG28 and AWG26.

Shielding Performance:Copper mesh braided shielding with an optical density of approximately 85%effectively prevents electromagnetic interference.

Product Features

Strong Compatibility:The FX3-MOC Y-CABLE is compatible with various types of encoders,including HTL,TTL,and sine/cosine encoders,meeting the needs of different application scenarios.

Stable Signal Transmission:High-quality shielding cables and reliable connection designs ensure stable and accurate signal transmission.

Flexible Installation:Multiple cable length options are available to adapt to different installation environments and equipment layouts.

Application Scenarios

The FX3-MOC Y-CABLE is widely used in the field of industrial automation,especially in applications requiring high-precision motion control.For example,in robotics,it can be used to connect encoders to controllers for precise position and speed control.Additionally,it is suitable for machine tools,conveyor belts,and other automated equipment to ensure efficient operation.

Installation and Connection

Connection Method:Connect the Micro D-Sub 15-pin plug to the FX3-MOC interface of the SICK module and the two M12 8-pin sockets to the HTL or TTL encoder.

Installation Environment:Choose a dust-free,non-corrosive gas environment with good ventilation,avoiding high temperatures,high humidity,and strong electromagnetic interference.

Parameter Settings

Signal Type Selection:Choose between HTL,TTL,or sine/cosine signal types based on actual requirements.

Shielding Grounding:Ensure that the cable's shielding layer is well-grounded to reduce electromagnetic interference.

Maintenance and Inspection

Regular Inspection:Check the cable's appearance for damage and ensure connections are secure.

Cleaning and Maintenance:Regularly clean dust and debris from the cable to ensure proper operation.

Precautions

Environmental Conditions:Avoid using in high-temperature,high-humidity,or strong electromagnetic interference environments.

Signal Matching:Ensure that the encoder's signal type is compatible with the FX3-MOC Y-CABLE.

Installation Standards:Follow the instructions carefully to avoid signal transmission issues due to improper installation.

Materials and Manufacturing Processes

The FX3-MOC Y-CABLE uses high-quality PVC material for the cable jacket,offering excellent corrosion and wear resistance to withstand harsh industrial conditions.The internal conductors are made of high-purity copper wire,ensuring low impedance and efficient signal transmission.The shielding layer is designed with a copper mesh braiding process,achieving a shielding density of up to 85%to effectively prevent electromagnetic interference and maintain signal integrity.

In terms of connectors,both the Micro D-Sub 15-pin plug and the M12 8-pin sockets are manufactured with high-precision molds to ensure reliable and durable contact points.The connector housing is made of high-strength plastic and metal materials,treated specially to provide excellent impact resistance and protection.

Additionally,the SICK module itself is manufactured using advanced processes.Its housing is made of high-strength aluminum alloy,offering good heat dissipation and electromagnetic interference resistance.The internal circuit design is optimized to perfectly match the signals from HTL and TTL encoders.

Additional Features

The FX3-MOC Y-CABLE is not just a simple connector cable;it also offers several additional features to meet complex industrial automation needs.For example,its built-in signal conditioning circuit can automatically recognize and adapt to the signal levels of HTL and TTL encoders,ensuring distortion-free signal transmission.

Moreover,the cable supports various signal transmission modes,including differential signal transmission,which further enhances the signal's interference resistance and transmission distance.This design makes the FX3-MOC Y-CABLE suitable for a wide range of complex industrial scenarios,whether in high-temperature,high-humidity environments or those with strong electromagnetic interference.

Product Advantages

In its design and manufacturing,the FX3-MOC Y-CABLE fully considers the needs of industrial automation,offering significant product advantages.First,it provides extremely stable signal transmission,ensuring error-free signal transfer between the SICK module and HTL or TTL encoders.This stability is crucial for high-precision motion control systems,such as those used in robotics and CNC machines.

Second,the cable's strong interference resistance effectively guards against electromagnetic interference and environmental noise,ensuring signal integrity.This allows the FX3-MOC Y-CABLE to maintain reliable performance even in harsh industrial environments.

Finally,its flexible connection design and multiple cable length options enable users to customize installations based on specific application scenarios.This flexibility greatly enhances the product's versatility and applicability.

After-Sales Service

SICK offers comprehensive after-sales services for the FX3-MOC Y-CABLE and its accompanying SICK modules.Users can access a 24-hour technical support hotline to receive professional guidance at any time.Additionally,SICK provides remote diagnostic services,helping users quickly identify and resolve equipment failures through secure network connections.

To ensure long-term stable operation of the equipment,SICK also offers preventive maintenance services,including regular equipment performance checks,calibration of measurement accuracy,and replacement of worn parts.These services effectively reduce equipment failure rates and extend service life.

Furthermore,SICK provides extended warranty services.Users can choose to extend the warranty period based on their needs,ensuring protection beyond the standard warranty period.This comprehensive after-sales service system provides strong support for users,ensuring efficient operation of the equipment throughout its entire lifecycle.

Frequently Asked Questions(FAQ)

1.How to Ensure Compatibility Between the FX3-MOC Y-CABLE,SICK Module,and TTL Encoder?

Interface Matching:The FX3-MOC Y-CABLE is designed specifically for SICK modules,with its Micro D-Sub 15-pin plug perfectly matching the module's interface.When connecting a TTL encoder,ensure that the encoder's interface is compatible with the cable's M12 8-pin socket.TTL encoders typically output low-voltage signals,so pay special attention to whether the signal level meets the requirements of the SICK module.

Signal Integrity:TTL encoder signal transmission requires high cable shielding performance.The FX3-MOC Y-CABLE's high-quality copper mesh shielding effectively prevents electromagnetic interference,ensuring signal integrity and accuracy.In practical applications,it is recommended to keep signal lines away from power lines to reduce interference.

Parameter Settings:When connecting a TTL encoder to the SICK module,correctly set the parameters in the SICK module to match the signal type and frequency range of the TTL encoder.Ensure that the encoder's resolution and output signal format match the input requirements of the SICK module to achieve efficient signal transmission and control.

2.How to Resolve Signal Interference Issues When Connecting HTL Encoders with the FX3-MOC Y-CABLE?

Shielding and Grounding:HTL encoders output high-voltage signals,which have strong interference resistance but still require good shielding and grounding measures.The copper mesh shielding layer of the FX3-MOC Y-CABLE effectively isolates external electromagnetic interference.Ensure that the shielding layer is well-grounded,which can further reduce the impact of interference.During installation,connect the shielding layer to the grounding terminal of the SICK module to form a complete grounding loop.

Wiring Standards:When connecting HTL encoders,it is recommended to separate signal lines from power lines to avoid electromagnetic coupling between them.If possible,use independent conduits or pipes to lay signal and power lines separately.Additionally,minimize bends and twists in signal lines to reduce signal transmission losses and interference.

Device Compatibility:Ensure that the signal levels and transmission rates of the HTL encoder and SICK module match.Mismatch in signal levels or transmission rates may cause signal distortion or interference.If necessary,use external circuits or adapters to convert signal levels to ensure stable signal transmission.

3.How to Choose TTL or HTL Encoders Compatible with the FX3-MOC Y-CABLE?

Signal Type Matching:The FX3-MOC Y-CABLE supports multiple types of encoders,including TTL and HTL.TTL encoders are typically used for short-distance transmission and output low-voltage signals,making them suitable for applications requiring high precision.HTL encoders output high-voltage signals,which are more suitable for long-distance transmission and have stronger interference resistance.Users should select the appropriate encoder type based on their specific application needs.

Interface Compatibility:When selecting an encoder,ensure that its interface is compatible with the M12 8-pin socket of the FX3-MOC Y-CABLE.Additionally,check whether the encoder's output signal format matches the input requirements of the SICK module.For TTL encoders,also ensure that the output current meets the input requirements of the SICK module to avoid signal attenuation or distortion.

Performance Parameters:Besides signal type and interface compatibility,consider the encoder's resolution,accuracy,and response speed.For high-precision applications,high-resolution TTL encoders are recommended.For applications requiring long-distance transmission or operation in harsh environments,HTL encoders are preferred.Additionally,select the appropriate encoder brand and model based on the actual requirements of the SICK module.

4.How to Ensure Signal Stability When Connecting the FX3-MOC Y-CABLE to the SICK Module?

Installation Environment:When connecting the SICK module and encoder,choose a dust-free,non-corrosive gas environment with good ventilation,avoiding high temperatures,high humidity,and strong electromagnetic interference.These environmental factors can affect the signal transmission performance of the FX3-MOC Y-CABLE,leading to signal attenuation or interference.Also,ensure that the cable is installed away from high-voltage equipment and high-current lines.

Cable Quality:The FX3-MOC Y-CABLE uses high-quality PVC material and copper mesh shielding to effectively prevent electromagnetic interference.Avoid excessive bending or pulling of the cable during use to prevent damage to its internal structure.Regularly inspect the cable's appearance and connections,and clean dust and debris to ensure long-term stable operation.

Parameter Settings:Correctly setting parameters in the SICK module is key to ensuring signal stability.Configure the parameters according to the signal type and frequency range of the connected TTL or HTL encoder.Ensure that the encoder's resolution and output signal format match the input requirements of the SICK module to achieve efficient signal transmission and control.

5.How to Resolve Signal Attenuation Issues When Connecting TTL Encoders with the FX3-MOC Y-CABLE?

Cable Length:TTL encoders output low-voltage signals,which are prone to signal attenuation during transmission.When selecting the FX3-MOC Y-CABLE,choose a shorter cable length to reduce transmission distance.Generally,the transmission distance for TTL signals should not exceed 10 meters to avoid signal distortion or failure to recognize the signal.

Signal Amplification:If longer transmission distances are required,use external signal amplifiers or repeaters to boost the signal.Signal amplifiers can increase the voltage and current of the signal,thereby extending the transmission distance.When selecting a signal amplifier,ensure it is compatible with the signal format of the TTL encoder and the SICK module.

Parameter Optimization:In the SICK module,adjust the signal filtering parameters to reduce the impact of signal noise.Ensure that the output signal frequency of the encoder matches the input frequency range of the SICK module to minimize signal distortion.If signal attenuation persists,consider reducing the encoder's resolution or adjusting its output signal format to improve signal stability and reliability.

6.How to Ensure Signal Integrity When Connecting HTL Encoders with the FX3-MOC Y-CABLE?

Shielding and Grounding:Although HTL encoders output high-voltage signals with strong interference resistance,good shielding and grounding measures are still necessary.The copper mesh shielding of the FX3-MOC Y-CABLE effectively isolates external electromagnetic interference.Ensure that the shielding layer is well-grounded by connecting it to the grounding terminal of the SICK module to form a complete grounding loop.

Wiring Standards:When connecting HTL encoders,separate signal lines from power lines to avoid electromagnetic coupling.If possible,use independent conduits or pipes for signal and power lines.Additionally,minimize bends and twists in signal lines to reduce signal transmission losses and interference.

Device Compatibility:Ensure that the signal levels and transmission rates of the HTL encoder and SICK module match.Mismatch in signal levels or transmission rates may cause signal distortion or interference.If necessary,use external circuits or adapters to convert signal levels to ensure stable signal transmission.

7. How to Choose SICK Modules Compatible with the FX3-MOC Y-CABLE?

Interface Compatibility:The FX3-MOC Y-CABLE is designed specifically for SICK modules,with its Micro D-Sub 15-pin plug perfectly matching the module's interface.When selecting a SICK module,ensure that its interface type matches the cable's connection method.Additionally,check whether the module's input signal format supports the output signals from TTL or HTL encoders.

Functional Requirements:Choose the appropriate SICK module based on your specific application needs.For example,for high-precision motion control applications,select a module that supports high-resolution encoder inputs.For applications requiring long-distance transmission,choose a module that supports HTL signals.Additionally,consider other functional characteristics of the SICK module,such as communication interfaces,control methods,and protection features.

Brand and Quality:SICK is a well-known manufacturer of industrial automation equipment,and its modules are known for high quality and compatibility.When selecting a SICK module,prioritize original products to ensure perfect compatibility with the FX3-MOC Y-CABLE.Additionally,refer to user reviews and technical support documentation to select the appropriate module model for your application.

8.How to Resolve Electromagnetic Interference Issues When Connecting the FX3-MOC Y-CABLE to the SICK Module?

Shielding and Grounding Measures:Electromagnetic interference is a common issue in industrial automation environments,especially when connecting SICK modules and encoders.The FX3-MOC Y-CABLE itself has effective copper mesh shielding to isolate external electromagnetic interference.However,to further reduce interference,ensure that the cable's shielding layer is well-grounded to form a complete grounding loop.Grounding is a key measure to reduce electromagnetic interference,as it directs interference signals into the ground,protecting signal integrity.

Wiring Standards and Device Compatibility:When connecting SICK modules and encoders,strictly follow wiring standards.Separate signal lines from power lines to avoid electromagnetic coupling.If possible,use independent conduits or pipes for signal and power lines.Additionally,ensure that the signal levels and transmission rates of the SICK module and encoder match to avoid signal distortion due to mismatched levels or rates.

External Protection and Professional Support:In complex environments,additional protective measures may be necessary to address electromagnetic interference.For example,install isolation transformers or EMI filters between power lines and signal lines to further reduce interference.If problems persist,seek help from professional EMC engineers or consultants who can provide targeted solutions.

9.How to Resolve Signal Attenuation Issues When Connecting TTL Encoders with the FX3-MOC Y-CABLE?

Cable Length and Signal Amplification:TTL encoders output low-voltage signals,making them susceptible to signal attenuation over long distances.To avoid this,choose a shorter FX3-MOC Y-CABLE to minimize transmission distance.If longer distances are necessary,consider using signal amplifiers or repeaters to boost the signal.

Parameter Optimization and Device Matching:When connecting TTL encoders to the SICK module,correctly set the parameters in the SICK module to match the signal type and frequency range of the TTL encoder.Additionally,ensure that the encoder's resolution and output signal format match the input requirements of the SICK module to reduce signal distortion.

Environmental Adaptability and Maintenance:The performance of TTL encoders and cables can also be affected by environmental factors.Signal attenuation may be more severe in high-temperature,high-humidity,or high-interference environments.Therefore,install the system in a dust-free,non-corrosive gas environment with good ventilation.Regularly inspect the connections of the cable and encoder,and clean dust and debris to ensure stable operation.

10.How to Ensure Signal Integrity When Connecting HTL Encoders with the FX3-MOC Y-CABLE?

Importance of Shielding and Grounding:Although HTL encoders output high-voltage signals with strong interference resistance,good shielding and grounding are still essential for signal integrity.The copper mesh shielding of the FX3-MOC Y-CABLE effectively isolates external electromagnetic interference.Grounding is crucial for reducing interference.Ensure that the shielding layer is well-grounded and connected to the grounding terminal of the SICK module to form a complete grounding loop.

Wiring Standards and Signal Matching:When connecting HTL encoders,separate signal lines from power lines to avoid electromagnetic coupling.Ensure that the signal levels and transmission rates of the HTL encoder match those of the SICK module to avoid signal distortion due to mismatched levels or rates.Regularly inspect the cable connections for solidity and check the cable's appearance for damage to ensure stable signal transmission.

External Protection and Professional Support:In complex environments,additional protective measures may be necessary to address electromagnetic interference.For example,install isolation transformers or EMI filters between power lines and signal lines.If problems persist,seek help from professional EMC engineers or consultants who can provide targeted solutions.

FAQ

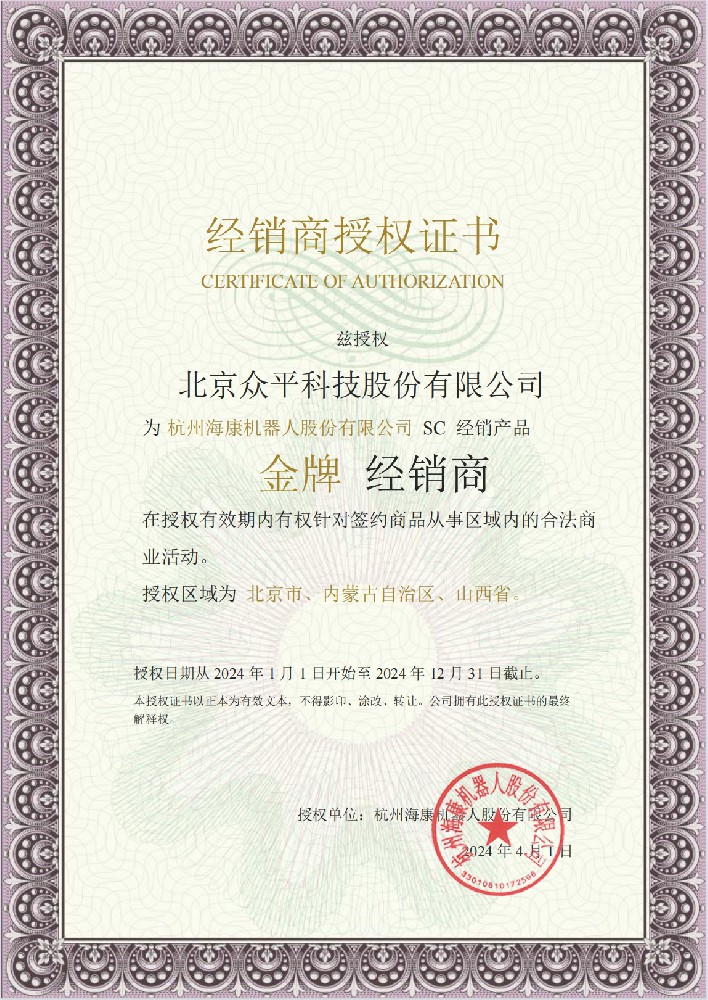

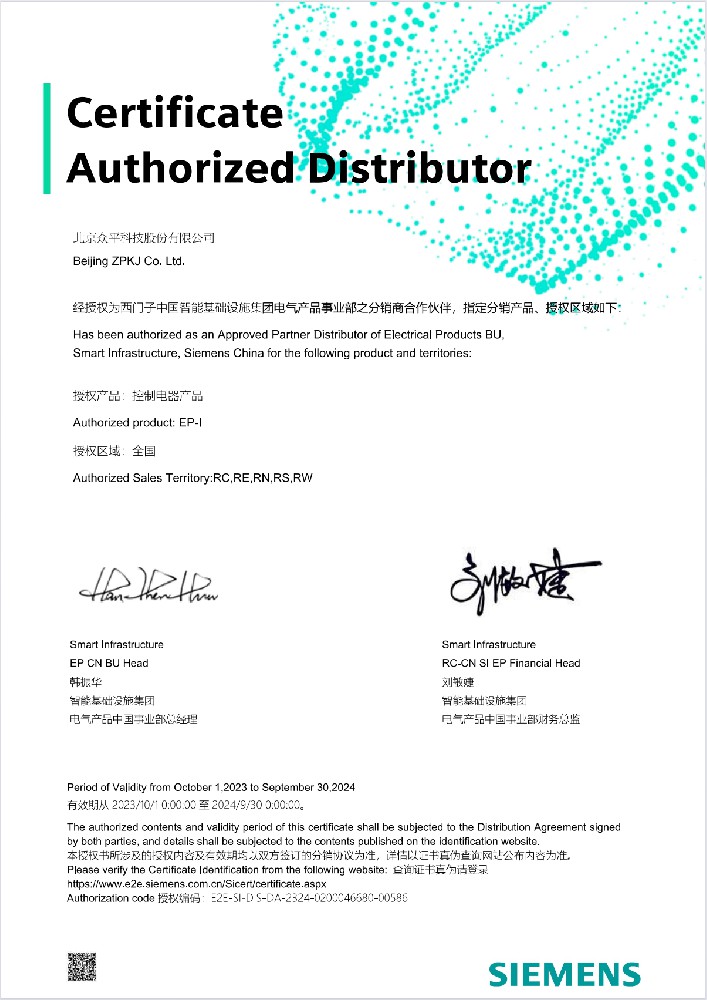

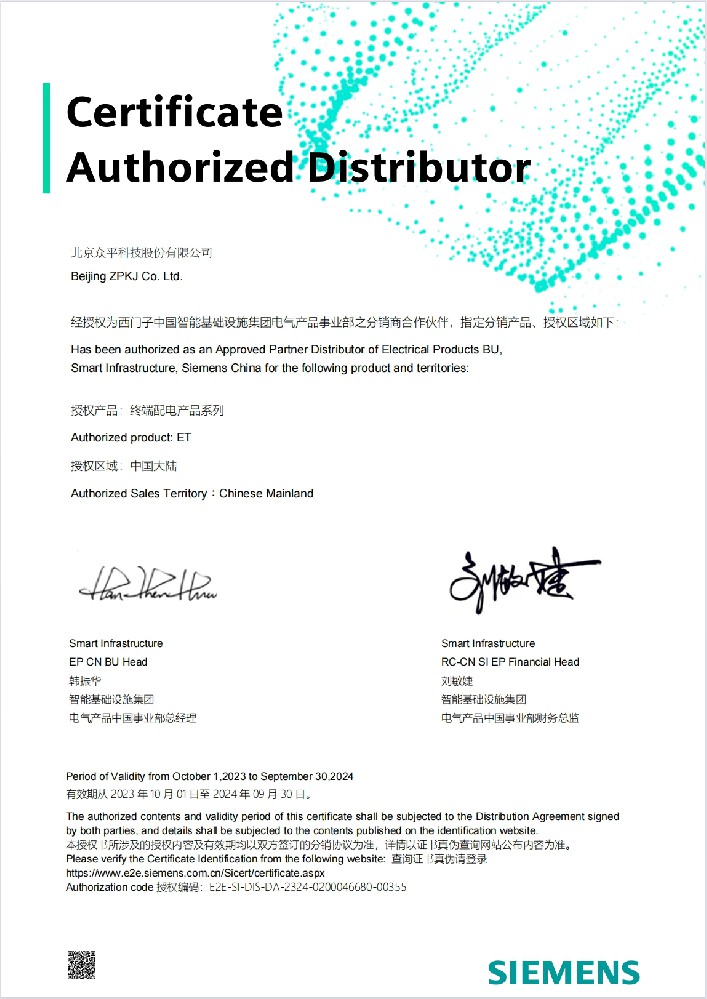

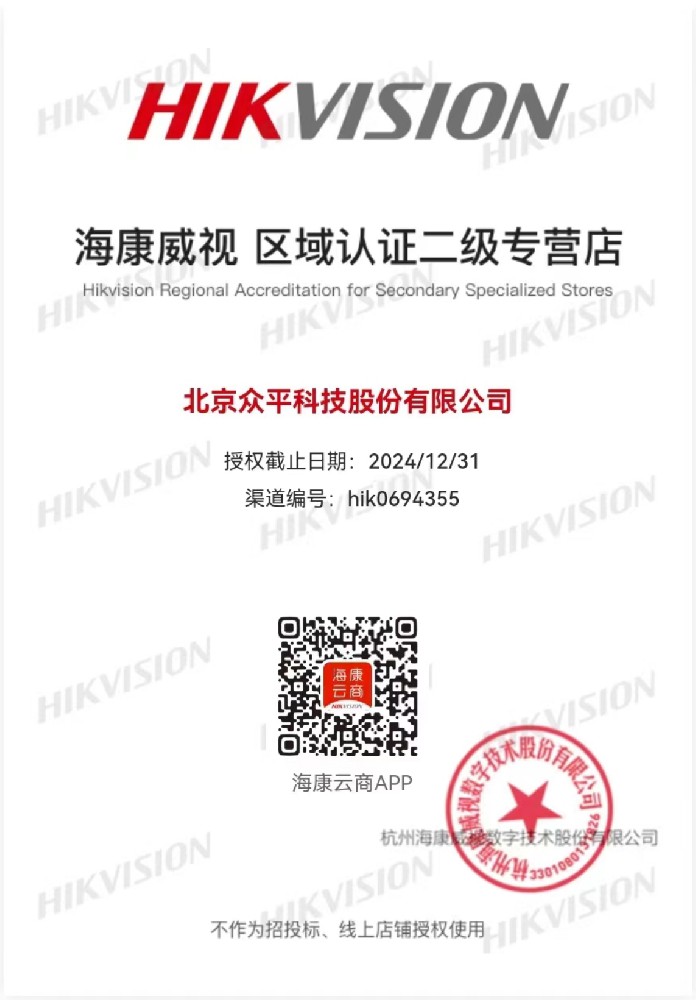

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China