The SMC AV3000-F03-5DZB-Q is a high-performance pneumatic valve and solenoid valve from SMC pneumatics. It is designed for industrial automation and pneumatic control systems, enabling low-speed air supply and rapid exhaust, effectively protecting the pneumatic system from sudden pressure changes. With its high efficiency, energy-saving capabilities, and precise control, it has become an ideal choice for modern industrial automation, especially in pneumatic valve applications.

Product Specifications

Main body size: 30mm, corresponding to a standard 3/8-inch size.

Thread type: Rc.

Connection port diameter: 3/8 inch.

Coil rated voltage: DC 24V.

Wire connection method: Type D DIN socket with plug.

Flow characteristics: C value of 9.2 dm³/(s·bar), with a flow performance 2.3 times higher than previous models.

Ambient temperature: -5°C to +60°C.

Pressure resistance: Maximum pressure resistance of 3.0 MPa.

Maximum operating pressure: 2.0 MPa.

Power consumption: 0.35W.

Product Features

Precise Control: The low-speed air supply function allows the initial pressure in the pneumatic valve system to rise gradually. After cutting off the air supply, rapid exhaust can be performed, effectively protecting the equipment.

Energy-Saving: The main valve switches with zero airflow, further reducing energy consumption.

Built-in Muffler: Saves space and reduces installation time.

Manual Operation: Push-rotate-lock screwdriver operation type, convenient for manual control in emergency situations.

Safety Protection: Built-in overvoltage protection circuit ensures safe operation of the equipment in complex environments.

Application Scenarios

The SMC AV3000-F03-5DZB-Q is widely used in automated machinery, pneumatic control systems, and other fields, especially in applications requiring precise control of start-up speed to protect the system or enhance comfort. Its high efficiency, energy-saving, and precise control features make it an ideal choice for modern industrial automation, especially in SMC pneumatics applications. For example:

Automated Production Lines: Controls the start and stop of air cylinders, reducing equipment shock during start-up.

Machine Tools: In lathes, drilling machines, and other equipment, precise control of the start-up speed of pneumatic components improves machining accuracy and product quality.

Food Processing Industry: Reduces pressure fluctuations in pneumatic systems in frequently started and stopped equipment, extending equipment life.

Installation and Wiring

Installation Environment: Choose a well-ventilated, dust-free, and non-corrosive gas environment for installation. Avoid installing the solenoid valve in high-temperature, high-humidity, or strong electromagnetic interference environments.

Installation Method: Ensure the solenoid valve is installed vertically for proper heat dissipation. Use appropriate fixing methods to avoid vibration impacts on the equipment.

Power Connection: When connecting the power supply, ensure the power cable meets the required specifications and pay attention to the correct phase sequence. Ensure proper grounding of the equipment.

Maintenance and Inspection

Regular Appearance Check: Inspect the solenoid valve for any damage or abnormalities, such as cracks in the casing or loose screws.

Clean the Heat Sink: Regularly remove dust from the heat sink to ensure the cooling system operates normally.

Check Electrical Connections: Ensure power and signal lines are securely connected and have good contact.

Precautions

Environmental Conditions: Avoid using the product in high-temperature, high-humidity, or strong electromagnetic interference environments to prevent performance and lifespan issues.

Power Requirements: Ensure stable power voltage to avoid damage to the pneumatic valve from voltage fluctuations.

Safe Operation: Avoid contact with live parts during operation to ensure operator safety. Disconnect power and wait for capacitor discharge before maintenance and inspection.

Frequently Asked Questions (FAQ)

How does the pneumatic valve function in industrial automation?

The pneumatic valve in industrial automation is used to control the airflow within pneumatic systems, regulating air supply and exhaust. The valve gradually increases airflow during startup to prevent equipment shock from sudden pressure changes, ensuring smooth operation. This controlled airflow helps to protect air cylinders and prevent sudden damage to equipment. The ability of solenoid valves to rapidly exhaust air after cutting off the supply ensures the system responds quickly, further optimizing the process flow. This feature is essential for industries requiring high-speed and efficient production cycles.

What is the maximum flow rate of a pneumatic valve in industrial systems?

The maximum flow rate of pneumatic valves is a critical factor in determining the speed and efficiency of pneumatic systems. High flow rates enable quick responses to system needs, improving overall process efficiency. In some solenoid valves, flow rates can reach up to 9.2 dm³/(s·bar), providing fast air supply and exhaust capabilities. This is especially useful in automated environments where quick start-stop cycles are needed, such as in manufacturing or packaging industries. Additionally, efficient flow control ensures reduced energy consumption and less wear on the system components, ensuring long-term performance.

What should be considered when installing solenoid valves in an industrial system?

When installing solenoid valves in a pneumatic system, it's important to ensure that they are placed in environments free of excessive dust, heat, or humidity, as these conditions can affect performance. The valves should be installed in positions that allow for easy maintenance and access. Proper sealing of pneumatic connections is also essential to avoid leaks, and the valve should be securely mounted to prevent vibration or damage. Correct wiring and power supply configuration are vital for optimal function, ensuring minimal energy loss during operation.

How does a solenoid valve ensure energy efficiency?

A solenoid valve ensures energy efficiency through its ability to minimize unnecessary energy consumption. Some models, like the SMC AV3000-F03-5DZB-Q, feature zero airflow during main valve switching, which prevents the wastage of energy when air is not needed. Additionally, the low power consumption of just 0.35W reduces the valve’s overall energy demand. By optimizing the electromagnetic coil design, these valves can operate efficiently, reducing the overall energy costs of pneumatic systems while still delivering fast, reliable performance.

What is the purpose of the pneumatic valve's rapid exhaust feature?

The pneumatic valve's rapid exhaust feature ensures quick release of air when the supply is cut off, helping to prevent pressure buildup that could damage the system. This feature is particularly important in high-speed automated applications, where rapid response times are crucial. The ability to quickly exhaust air improves system stability and efficiency by reducing the time needed for air release, ensuring that production processes are not delayed due to slow venting.

What maintenance is required for pneumatic valves?

Regular maintenance of pneumatic valves ensures optimal performance and longevity. Key tasks include checking for physical damage, inspecting seals and fittings for leaks, and cleaning dust from air inlets to maintain airflow. It's also important to verify the electrical connections and confirm the valve’s parameter settings to ensure they align with system requirements. Routine inspections and timely maintenance prevent unnecessary downtime and costly repairs, keeping solenoid valves functioning efficiently throughout their service life.

What are the advantages of using solenoid valves in automated production lines?

Solenoid valves offer several advantages in automated production lines, particularly in terms of efficiency and reliability. They allow for precise control of airflow, reducing the chances of equipment damage from sudden air pressure fluctuations. The fast switching capability of these valves makes them ideal for automated processes that require rapid and repeated actions. Their ability to handle high-frequency switching ensures continuous operation in demanding environments, reducing downtime and improving overall productivity.

What are the safety features of SMC pneumatics valves?

SMC pneumatics valves, like the SMC AV3000-F03-5DZB-Q, come equipped with several safety features to protect both the valve and the system. These valves include overvoltage protection to prevent electrical surges and ensure safe operation. Additionally, the design minimizes pressure fluctuations, ensuring smooth and safe airflow during operation. The built-in manual operation function also allows for emergency control in case of power failure or system malfunction, providing added security in critical applications.

Can pneumatic valves be used in high-pressure environments?

Yes, pneumatic valves can be used in high-pressure environments, depending on the model. For instance, some valves are designed to handle pressures of up to 2.0 MPa, making them suitable for industries with demanding pressure requirements. These valves are built to withstand pressure spikes, ensuring reliable operation under high-pressure conditions without compromising system stability. It's important to select the right valve for your specific application to ensure safety and optimal performance.

How does a solenoid valve improve system response time?

A solenoid valve improves system response time by quickly controlling the flow of air within the pneumatic system. With fast switching capabilities, these valves can provide rapid airflow and exhaust, ensuring that pneumatic actuators respond quickly to control signals. This is particularly important in applications requiring high-speed automation, where precise and immediate actions are essential. The efficient flow regulation provided by solenoid valves ensures minimal delay, improving overall system efficiency.

FAQ

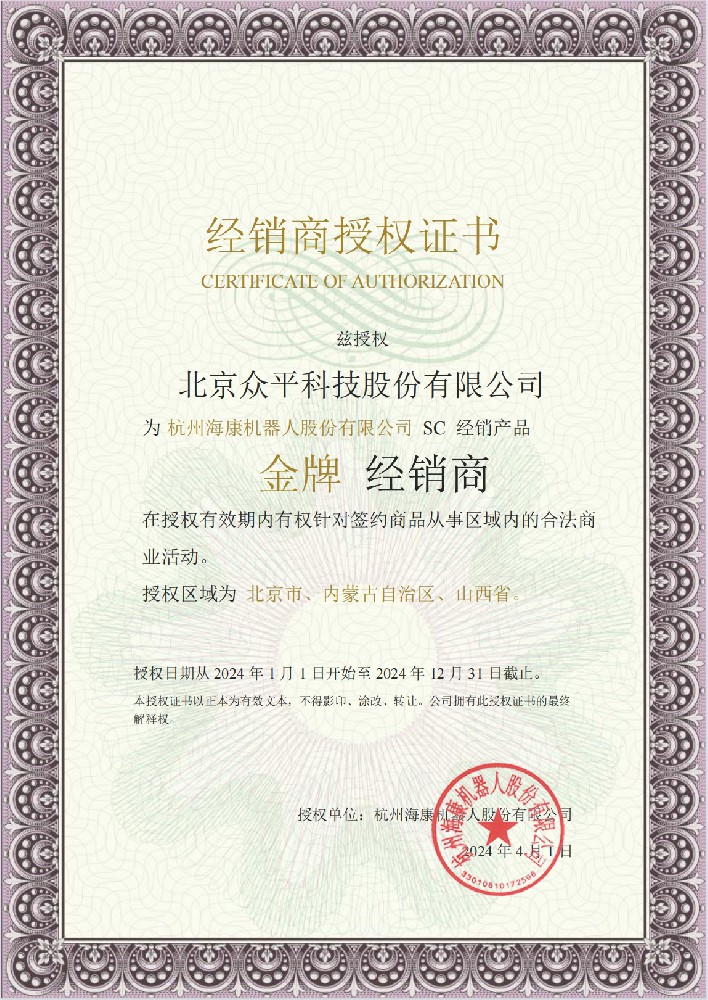

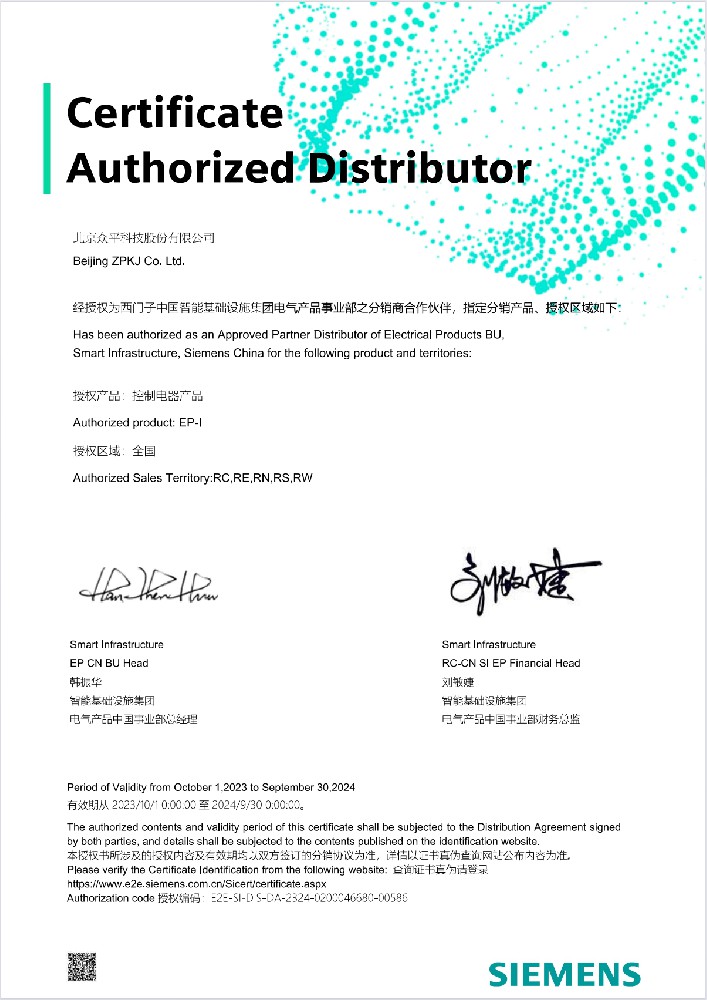

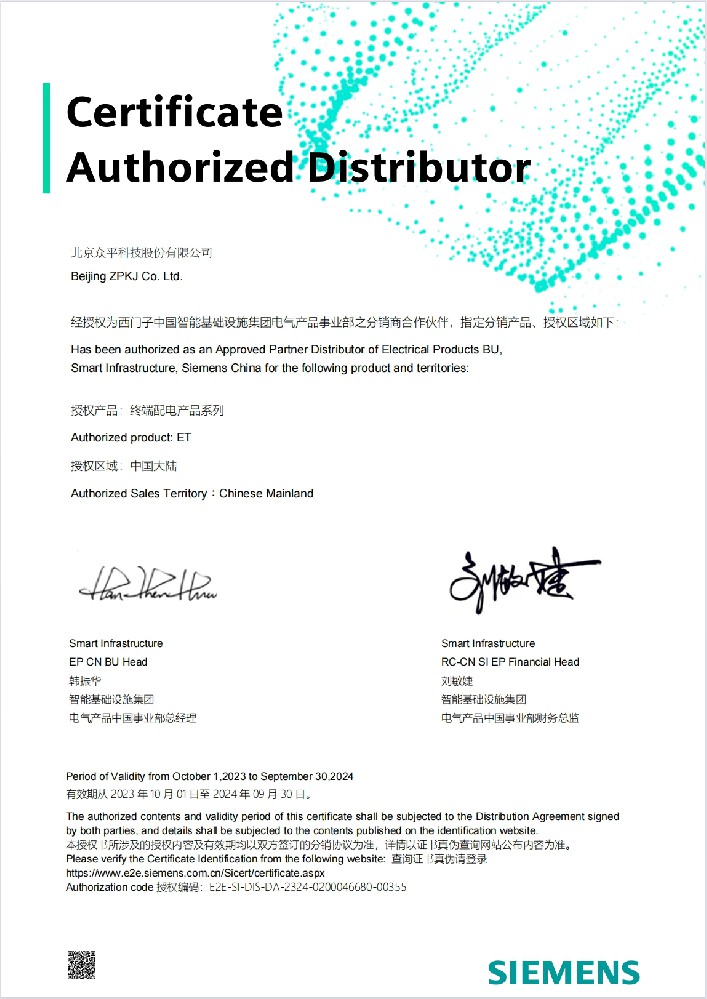

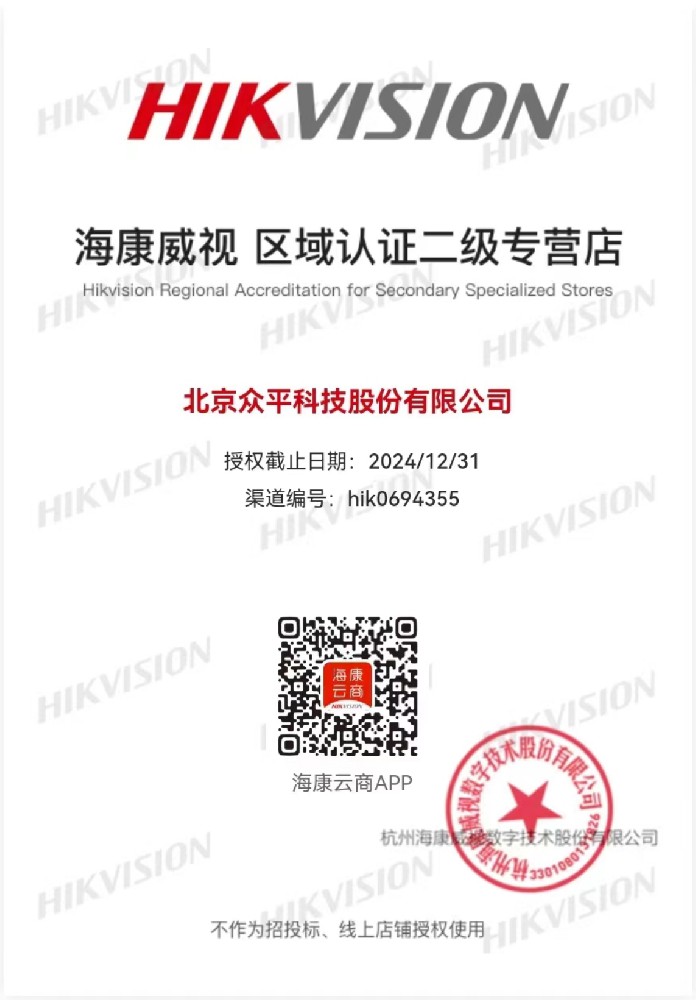

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China