As one of the SMC's KQ2 series, the SMC KQ2C06-00A 6mm polyurethane tubing cap is designed for using in the industrial control sector, particularly for connecting pipes and air tubing. Renowned for its superior performance and ease of use, this product is widely utilized in automated machinery, fluid control, and other applications. Here are some key specifications and features of the product:

Material: PBT (Polybutylene Terephthalate), known for its durability and high-temperature resistance.

Applicable Pipe Diameter: Suitable for pipes with an outer diameter of 6 millimeters.

Pressure Range: From -100 kPa to 1 MPa, ideal for low to medium pressure working environments.

Temperature Range: Operates between -5 to 60 degrees Celsius, making it suitable for a broad spectrum of industrial settings.

Sealing Method: Features a special profile sealing ring for excellent sealing performance.

Ease of Detachment: The KQ2 series' release ring design allows for quick and easy detachment.

Product Details

Brand: SMC

Model: KQ2C06-00A

Series: KQ2

Material: PBT

Applicable Pipe Diameter: 6mm

Pressure Range: -100 kPa to 1 MPa

Temperature Range: -5 to 60 degrees Celsius

Product Features

Quick Connection and Detachment: The KQ2 series' quick coupling design allows for rapid pipe connections and detachments.

Broad Application Scope: Ideal for various industrial automation and fluid control scenarios.

Excellent Sealing Performance: The special profile sealing ring ensures a tight seal under various pressures.

Application Scenarios

Automated Machinery: Used in automated production lines for quick connection and disconnection of pneumatic or hydraulic systems.

Fluid Control: Ideal for situations requiring frequent changes in fluid piping, such as laboratories and chemical industries.

Equipment Maintenance: Provides a convenient pipe connection solution when equipment needs rapid replacement or maintenance.

Usage Instructions

Installation: Ensure a tight fit between the cap and the pipe to prevent leaks.

Inspection: Check the integrity of the sealing ring before and after use to ensure sealing performance.

Maintenance: Regularly inspect the wear of the cap and replace it promptly to avoid leaks.

Precautions

Avoid High Temperatures: Do not use for extended periods in environments exceeding 60 degrees Celsius.

Correct Installation: Ensure the cap is installed correctly to prevent leaks due to improper installation.

Regular Checks: Regularly inspect the cap's sealing performance to ensure safe operation of the piping system.

Frequently Asked Questions (FAQ)

1. How does the SMC 6mm polyurethane tubing cap ensure excellent sealing performance?

The SMC cap utilizes a special profile sealing ring, which maintains excellent sealing performance across various pressures. Proper installation, ensuring a tight fit between the cap and the pipe, is crucial for good sealing. Regular inspection and timely replacement of the sealing ring are also essential for maintaining good sealing performance.

2. What is the temperature range for the SMC 6mm polyurethane tubing cap?

The SMC cap is designed to operate within a temperature range of -5 to 60 degrees Celsius, suitable for most industrial environments. However, extreme temperatures may affect the material properties and sealing performance, so it's important to ensure the environmental temperature is within the specified range before use.

3. How can the SMC cap be quickly detached with SMC air tubing?

One of the key features of the SMC cap is its quick detachment design. The KQ2 series cap comes with a release ring that allows for the simultaneous release of the clamp and the retainer, enabling swift detachment. To detach, simply pull the release ring, and the cap will come off the pipe, saving time during detachment processes.

4. What are the material characteristics of the SMC 6mm polyurethane tubing cap?

The primary material of the SMC cap is PBT (Polybutylene Terephthalate), a high-performance plastic widely used in industrial applications. PBT offers several advantages, making it an ideal material for manufacturing caps.

5. How is the sealing performance of the SMC cap in high-pressure environments?

The SMC cap is designed to work within a pressure range of -100 kPa to 1 MPa, covering low to medium pressure working environments. The special profile sealing ring ensures good sealing performance within these pressure ranges.

6. How to perform daily maintenance on the cap when connecting SMC air tubing?

Daily maintenance of the cap is essential to ensure its good working condition and extend its service life. Regularly inspect the cap for cracks, wear, or other signs of damage that may affect sealing performance and structural integrity. Check the sealing ring for wear, aging, or damage, and replace it immediately if necessary. Clean the cap regularly if it is used in harsh environments to prevent damage from dust or chemicals. Use the correct methods and tools when detaching and reattaching the cap to avoid damage.

7. What are the applicable scenarios for the cap?

Due to its quick connection and detachment features, as well as excellent sealing performance, the cap is suitable for a variety of industrial scenarios, including automated machinery, fluid control, equipment maintenance, and industrial robotics.

eight. What are the installation steps for the SMC cap?

The installation steps for the cap are as follows: prepare the necessary tools and materials, clean the pipe, install the sealing ring correctly, connect the cap to the pipe, check the seal, and perform a pressure test after installation to ensure sealing performance.

9. How to Prevent Pipe Fittings from Becoming Brittle in Low-Temperature Environments?

In low-temperature environments, pipe fittings should be made of materials that can withstand low temperatures to prevent brittleness or cracking.

Take insulation measures when storing and transporting fittings in low-temperature environments to avoid the impact of excessively low temperatures on the fittings.

Gradually increase pressure when using fittings in low-temperature environments to avoid damage due to large temperature differences.

10. How to Identify Genuine The SMC Pipe Fittings?

To identify genuine pipe fittings, check their packaging and markings; genuine products usually have clear brand identification and production dates.

Inspect the material and workmanship of the fittings; genuine fittings have high-quality materials and fine workmanship, with no obvious defects.

Purchase fittings through official channels to avoid counterfeit products.

FAQ

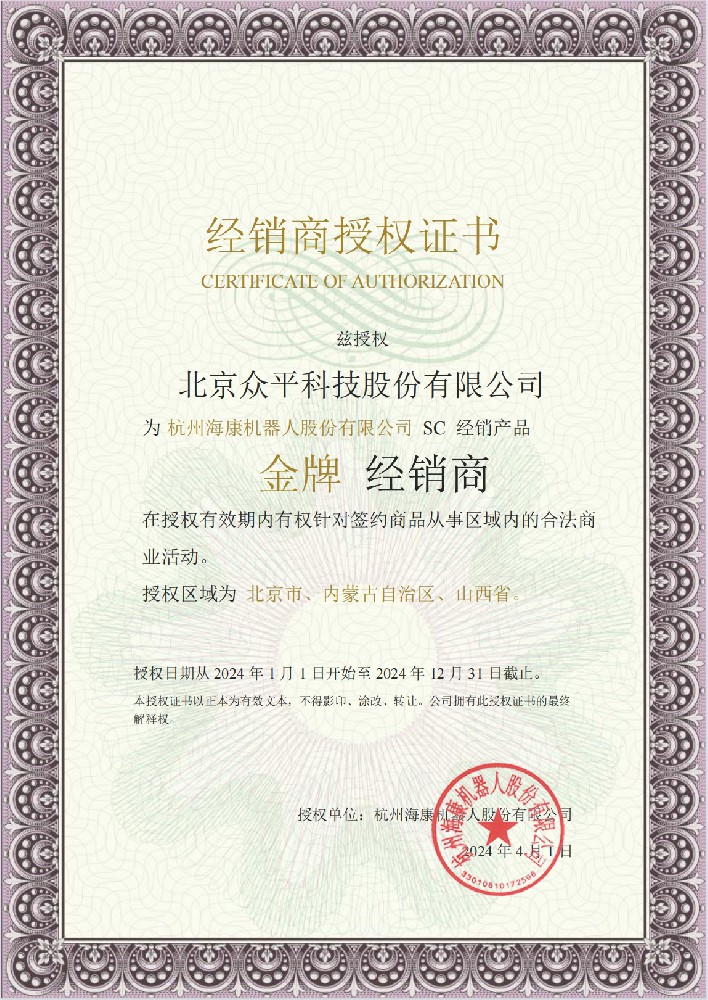

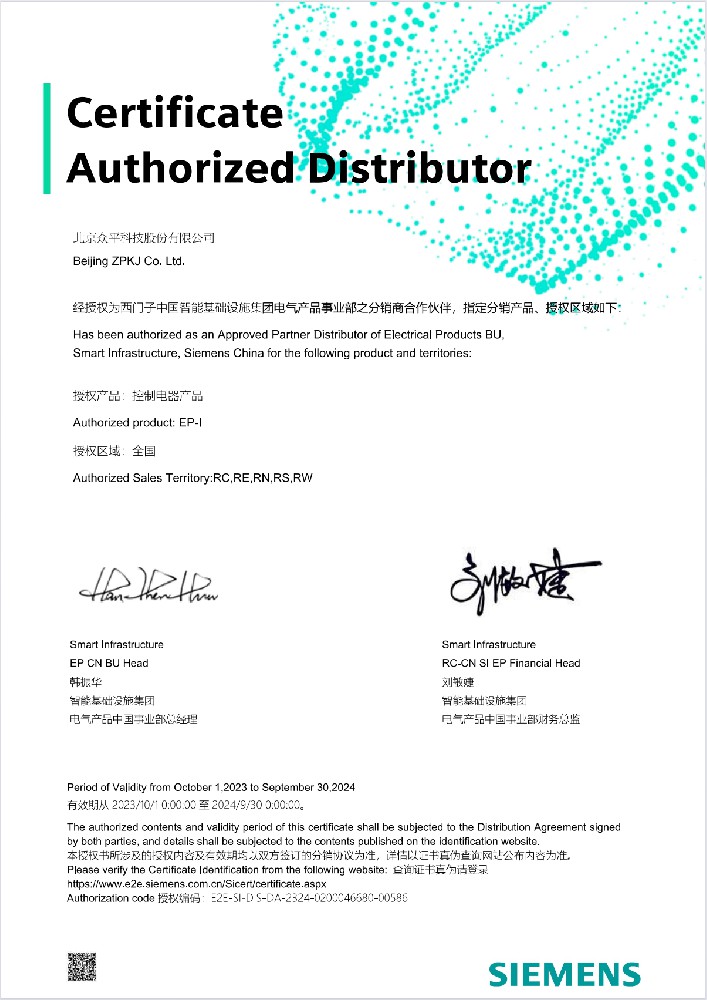

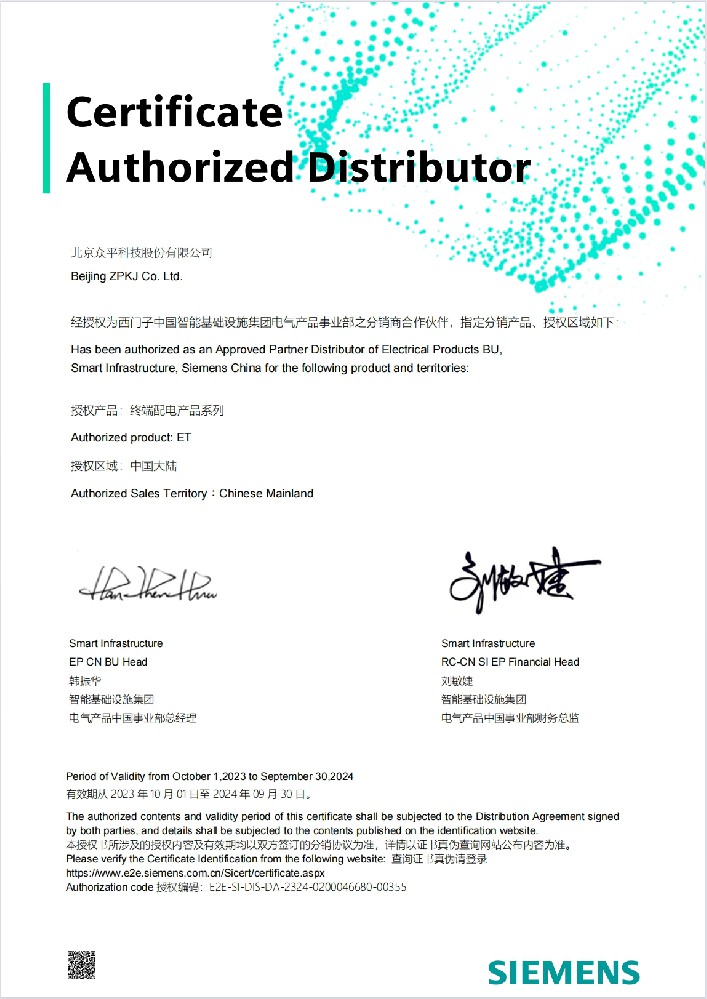

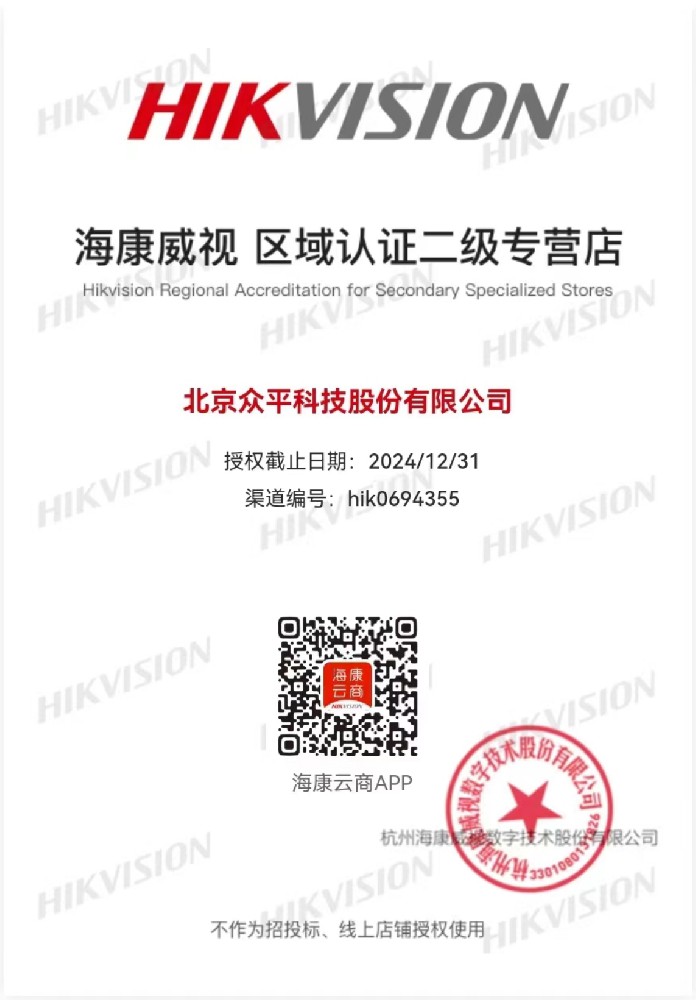

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China