As a one of the reliable tube fittings and pneumatics parts, the SMC KQ2P-10 is a quick pipe coupling produced by the Japanese SMC Corporation, renowned in the industrial control field for its superior performance and reliable connections. This coupling is made from brass, PBT (Polybutylene Terephthalate), and PP (Polypropylene) materials and is designed for 10mm tube connections. It's compact and lightweight, making it easy to install and remove quickly while maintaining high sealing and durability, making it an indispensable component in pneumatic systems.

Product Specifications

Model: SMC KQ2P-10

Materials: Brass, PBT, PP

Tube Diameter: 10mm

Working Pressure: Up to 10bar

Vacuum Working Pressure: Up to -100kPa

Pressure Test Pressure: 3MPa

Temperature Range: Ambient temperature -5°C to +60°C, Liquid temperature 0°C to 40°C

Connection Threads: Metric M3, M5, M6, Whitworth R, Rc, G, NPT, and Uni threads

Product Features

Compact Design: Small in size and light in weight, facilitating easy installation and maintenance.

High Sealing: Various sealing methods ensure leak-free performance suitable for high-pressure and vacuum environments.

Durable Materials: The brass body and PBT/PP materials offer excellent resistance to chemicals and temperature variations.

Quick Connection: Simplified connection mechanisms to increase work efficiency.

Application Scenarios

The SMC KQ2P-10 quick coupling is widely used in the following scenarios:

Automation Equipment: Used for pneumatic control and fluid transfer in robotic arms and automated assembly lines.

Industrial Machinery: Serving as the pneumatic interface for machines such as CNC machines and injection molding machines.

Laboratory Equipment: Used for precise control of gas and liquid flow in analytical instruments and testing devices.

Instructions for Use

Installation and Wiring

1. Ensure the working environment is dust-free and free from corrosive gases.

2. Wire according to the product manual to ensure the correct connection of power lines, signal lines, and tubing.

3. Implement grounding protection measures to ensure equipment safety.

Parameter Settings

1. Set the working pressure and temperature parameters based on application requirements.

2. Choose the appropriate sealing method to ensure system sealing integrity.

Maintenance and Inspection

1. Regularly inspect the appearance and connection status of the coupling, and replace damaged parts in a timely manner.

2. Check the wear of the sealing rings and O-rings, and replace them when necessary.

Precautions

1. Avoid using in extreme temperature and humidity conditions.

2. Ensure stable power supply voltage to prevent voltage fluctuations.

3. Operators should follow safety operation procedures.

Frequently Asked Questions (FAQ)

1. As one of the SMC tube fittings, what is the working pressure range of the product?

The working pressure range of SMC KQ2P-10 is 0 to 10bar, suitable for a variety of industrial applications, including automation equipment and industrial machinery. This broad working pressure range allows the coupling to adapt to different working conditions, whether high or low pressure environments.

When selecting a coupling, it's important to ensure that the working pressure does not exceed this range to avoid damage to the coupling. Additionally, the coupling has been designed with a safety factor to ensure long-term reliable operation.

The choice of working pressure should be determined based on actual application needs, while also considering the maximum pressure the system may experience to ensure the safety and durability of the coupling.

2. How to choose the right sealing method?

The choice of sealing method depends on the properties of the medium and the requirements of the system. SMC KQ2P-10 offers various sealing methods, including sealant/gasket sealing, sealing ring sealing, and Uni-thread sealing gasket sealing.

For example, for applications that require quick connection and disconnection, Uni-thread sealing gasket sealing can be chosen as it provides a fast and reliable seal. For applications that require long-term stable sealing, sealing ring sealing can be selected.

Choosing the right sealing method can also improve the reliability and safety of the system, reducing maintenance costs and downtime.

3. As one of the SMC tube fittings, what is the pressure test pressure of the product?

As one of the SMC tube fittings and pneumatics parts, The pressure test pressure of the part is 3MPa, indicating that the coupling has undergone strict quality control and testing during its design and manufacturing process to ensure its stability and reliability under high pressure.

Pressure testing is an important indicator for assessing the performance of a coupling, helping users understand the coupling's endurance under actual working conditions. The high pressure test pressure of the product means it can be safely used in high-pressure environments.

When selecting a coupling, users should ensure that its pressure test pressure meets or exceeds the maximum working pressure of the system to ensure the safety and stable operation of the system.

4. What are the ambient and liquid temperature ranges?

As a member of the pneumatics parts, the ambient temperature range of the product is -5°C to +60°C, and the liquid temperature range is 0°C to 40°C. This means the coupling can operate under a wide range of temperature conditions, suitable for different seasons and climates.

The choice of temperature range is crucial for ensuring the performance and durability of the coupling. For example, in cold environments, the coupling may become brittle due to low temperatures, while in high-temperature environments, the coupling may deform due to thermal expansion.

Users should select the appropriate coupling based on the temperature variations of the actual application environment and take appropriate protective measures, such as insulation and heat preservation, to ensure the performance and durability of the coupling.

5. Which connection threads will the pneumatics parts support?

SMC KQ2P-10 supports a variety of connection threads, including metric M3, M5, M6, Whitworth R, Rc, G, NPT, and Uni threads. This diversity allows the coupling to be compatible with various tubing and equipment, meeting the needs of different users.

The choice of connection threads depends on the interface standards and tubing configurations of the system. For example, metric threads are commonly used in European and Asian markets, while Whitworth threads are commonly used in North American markets.

When selecting a coupling, users should ensure that the selected threads match the tubing and equipment of the system to ensure reliable connection and sealing.

6. How to ensure the sealing integrity of the coupling?

Ensuring the sealing integrity of the coupling is key to ensuring the safety and stable operation of the system. SMC KQ2P-10 offers various sealing methods, and users should choose the appropriate sealing method based on actual application needs.

For example, for applications that require quick connection and disconnection, Uni-thread sealing gasket sealing can be chosen as it provides a fast and reliable seal. For applications that require long-term stable sealing, sealing ring sealing can be selected.

Users should also regularly inspect the wear of the sealing rings and O-rings and replace them when necessary to ensure the sealing integrity of the coupling.

7. What is the maintenance and inspection cycle for the SMC pipe part ?

The maintenance and inspection cycle for SMC KQ2P-10 should be determined based on the actual application environment and usage frequency. Generally, it is recommended to conduct a routine inspection every quarter and a deep maintenance once a year.

Regular inspections can及时发现 coupling wear and damage, reducing the risk of failure and leakage. Inspections include visual inspections, sealing ring inspections, and thread inspections.

Deep maintenance includes cleaning the coupling, replacing worn parts, and retightening threads. These measures can extend the service life of the coupling and improve system reliability.

8. How does the SMC pipe part perform under extreme temperatures?

SMC KQ2P-10 can operate under ambient temperatures ranging from -5°C to +60°C, indicating that the coupling can maintain stable performance under extreme temperature conditions.

In low-temperature environments, the coupling may become brittle due to differences in thermal expansion coefficients, while in high-temperature environments, the coupling may deform due to thermal expansion. The materials and design of the SMC pipe part have taken these factors into account to ensure good performance under extreme temperatures.

Users should select the appropriate coupling based on the temperature variations of the actual application environment and take appropriate protective measures, such as insulation and heat preservation, to ensure the performance and durability of the coupling.

9. What are the considerations for the installation and wiring of the product?

The installation and wiring of the product are critical steps to ensure the performance and safety of the coupling. Users should strictly follow the product manual for installation and wiring.

The installation environment should be dust-free and free from corrosive gases, and ensure good heat dissipation for the equipment. Wiring should be done strictly according to the wiring diagram in the product manual to ensure the correct connection of power lines, signal lines, and tubing.

Grounding protection measures are also very important to ensure equipment safety. Users should also ensure that the specifications of the power lines meet the requirements and pay attention to the correctness of phase sequence.

10. What is the service life of the product?

The service life of the product depends on various factors, including usage frequency, working conditions, and maintenance. Generally, if installed, used, and maintained correctly, the coupling can have a service life of several years or even longer.

Users should regularly inspect the appearance and connection status of the coupling and replace damaged parts in a timely manner. Regular maintenance can extend the service life of the coupling and reduce the risk of failure and leakage.

In addition, users should avoid using the coupling under extreme temperature and humidity conditions to affect its performance and life. Ensuring stable power supply voltage to prevent voltage fluctuations is also an important measure to extend the service life of the coupling.

FAQ

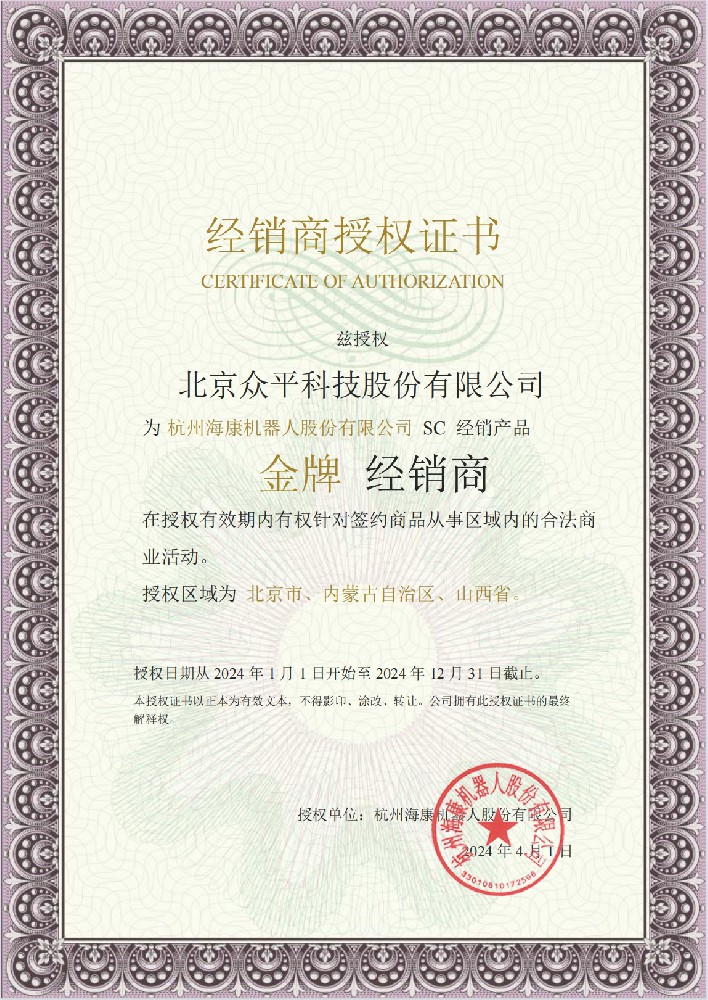

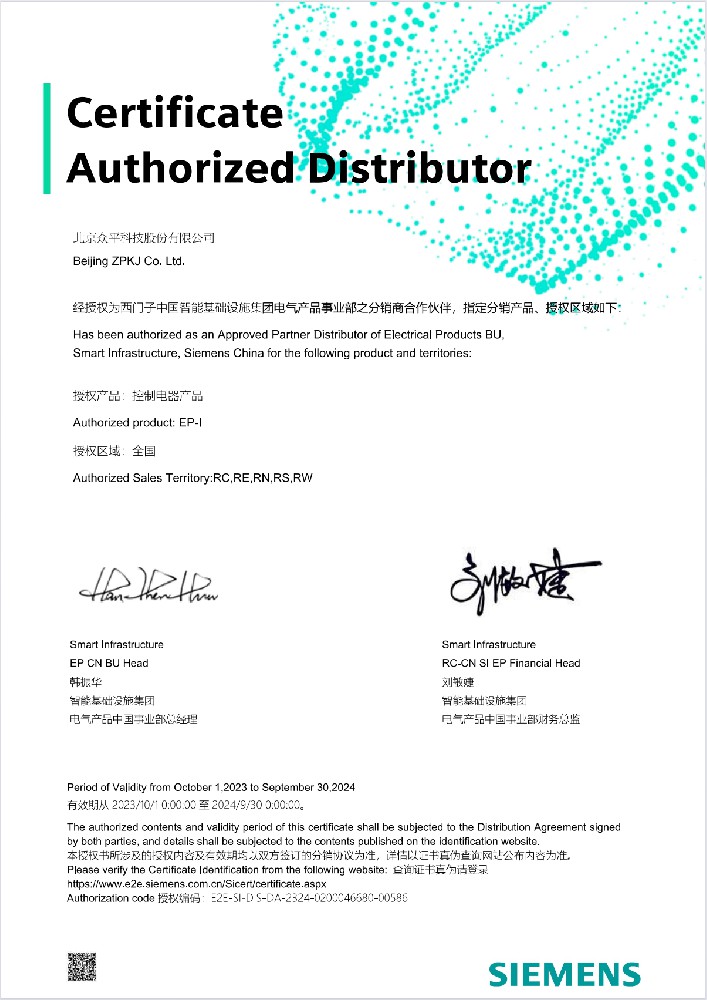

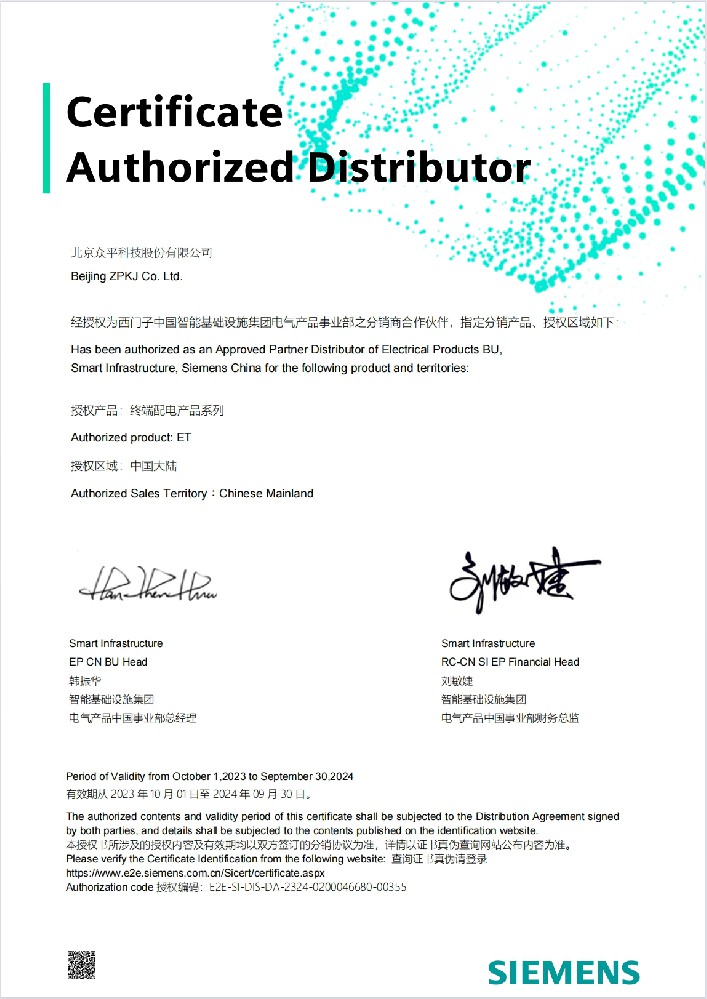

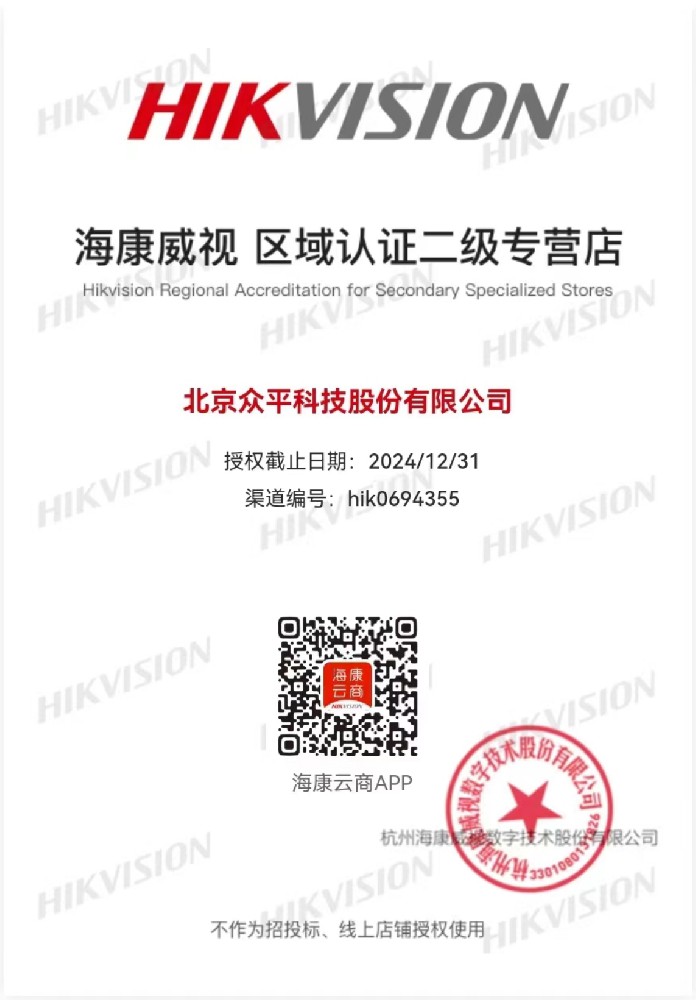

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China