The EX600-SPR1A is a fieldbus device introduced by SMC Corporation. This product is primarily used to control pneumatic valves, solenoid valves, pneumatic actuators, I/O devices, and other actuators to meet complex control requirements. The device features PNP output, an IP67 protection rating, and excellent dustproof and waterproof performance, ensuring reliable operation in harsh industrial environments. It supports the Profibus DP protocol.

Product Specifications

Power Requirements: Control and input power are 24 VDC Class 2, with a maximum of 2 A.

Output Type: PNP (sourcing, common negative).

Output Channels: Up to 32 channels, configurable as 8, 16, 24, or 32 points.

Load Capacity: Supports SMC brand solenoid valves with a maximum power of 1.5 W.

Environmental Adaptability: Operating temperature range of -10°C to +50°C, humidity range of 35% to 85% RH (non-condensing).

Protection Rating: IP67 (when used with a combination valve).

Product Features

High Integration: Supports up to 32 outputs, connecting various pneumatic valves.

Self-Diagnosis: Real-time monitoring of device status, supporting fault diagnosis and preventive maintenance.

Flexible Configuration: Compatible with multiple communication speeds and configuration files (GSD files), facilitating integration with different systems.

High Reliability: Built-in short-circuit protection ensures stable operation in complex industrial environments.

Applications

The EX600-SPR1A is widely used in the following areas:

Automated Production Lines: Controls pneumatic valves for precise material handling and processing.

Machine Manufacturing: In mechanical manufacturing, it is used to control pneumatic actuators in equipment such as machine tools and robots. It can accurately adapt to various pneumatic actuators, providing reliable guarantee for their efficient and stable operation under complex working conditions.

Food and Packaging Industry: Achieves fast and reliable automated operations in packaging equipment requiring high-precision control.

Logistics and Warehousing: Controls conveyor belts and automated storage equipment.

Installation and Wiring

Installation Environment: Choose a dust-free, non-corrosive gas, and low electromagnetic interference environment, ensuring good device ventilation.

Wiring Requirements: Follow the wiring diagram in the manual to ensure correct communication and power connections.

Grounding Protection: Ensure proper grounding of the device in accordance with electrical safety standards.

Parameter Settings

Communication Parameters: Set communication speed, address, and other parameters based on actual needs.

Output Configuration: Choose the number of output points according to application requirements and set the output behavior during communication faults (e.g., hold, clear, or force on).

Maintenance and Inspection

Regular Checks: Inspect the device's appearance, cooling system, and electrical connections.

Fault Diagnosis: Monitor device status via LED indicators and troubleshoot based on fault codes.

Precautions

Environmental Conditions: Avoid using in high-temperature, high-humidity, or high electromagnetic interference environments.

Power Requirements: Ensure stable power supply voltage to prevent damage from voltage fluctuations.

Safe Operation: Avoid contact with live parts during operation and disconnect power before maintenance.

Frequently Asked Questions (FAQ)

How to Configure Communication for EX600-SPR1A?

The EX600-SPR1A supports the PROFIBUS DP protocol with communication speeds ranging from 9.6 kbps to 12 Mbps. When configuring communication, set parameters such as speed and device address according to the requirements of the master controller.

Use shielded cables for communication lines to ensure signal stability and interference resistance. Ensure correct connections at the BUS IN and BUS OUT ports.

After configuration, check the communication status via the device's LED indicators. If communication is abnormal, verify that the communication parameters match the master controller.

How to Choose the Number of Output Points?

The EX600-SPR1A offers output configurations of 8, 16, 24, and 32 points. Select the number of output points based on actual application needs and the number of devices to be controlled.

For applications with a large number of devices to control, consider higher output configurations like 24 or 32 points. This reduces the number of devices, simplifies system structure, and lowers wiring complexity and costs. For example, in complex automated production lines, a 32-point configuration can meet most needs.

When selecting the number of output points, consider system scalability and future upgrade needs. Reserving sufficient output points allows for easy addition of new devices or functions without replacing the entire control unit. It is recommended to thoroughly assess overall system requirements during the design phase to ensure the selected output points meet current needs and future development.

How Does the Self-Diagnosis Function Work on EX600-SPR1A?

The EX600-SPR1A features built-in self-diagnosis capabilities to monitor its operating status in real-time. The self-diagnosis function primarily displays status information through LED indicators on the device. For example, a green light indicates normal operation, while a red or flashing light signals communication faults or hardware issues.

The self-diagnosis function can detect specific fault types, such as short circuits, overloads, or communication anomalies. When a fault is detected, the device automatically records a fault code. Users can quickly identify the problem by consulting the device's technical manual based on the fault code. For instance, if a short circuit occurs in the communication line, the device will display a specific fault code and halt communication to prevent further damage.

This function not only enhances device reliability but also reduces maintenance time and costs. Regularly checking the device's LED status and fault codes allows users to identify potential issues early and perform preventive maintenance. This ensures stable operation in complex industrial environments. Additionally, the self-diagnosis function supports remote monitoring, enabling users to obtain real-time device status information through the master controller and further improve system intelligence.

How to Ensure the Reliability of EX600-SPR1A in Harsh Environments?

Designed for industrial use, the EX600-SPR1A has a high protection rating (IP67), effectively guarding against dust, moisture, and other contaminants. When used in harsh environments, ensure the device is installed within an enclosure meeting the protection rating requirements and avoid direct exposure to liquids or corrosive gases. For example, in food processing or chemical plants, the device should be housed in a well-sealed protective cover to prevent erosion from liquids or chemicals.

To ensure reliability, pay attention to the protection of power and communication lines. Use shielded cables for communication connections and ensure proper grounding of the cable shield to minimize electromagnetic interference. Additionally, select appropriate power cables and avoid bundling them with communication lines to prevent power noise from affecting signal transmission. Proper grounding of the device is also crucial for safe operation.

Regular maintenance is key to ensuring reliable operation in harsh environments. Periodically inspect the device's appearance, clean dust and dirt, check the cooling system's functionality, and verify the integrity of electrical connections. If the device's enclosure is damaged or poorly sealed, replace or repair it promptly. These measures can effectively extend the device's lifespan and ensure stable operation in harsh conditions.

How Does the Short-Circuit Protection Function Work?

The EX600-SPR1A features built-in short-circuit protection to prevent device damage from accidental short circuits. When a short circuit is detected at the output, the device immediately cuts off the output power, protecting the internal circuitry and connected external devices. The response time of the short-circuit protection is typically in the millisecond range, allowing rapid power disconnection to prevent device burnout due to excessive short-circuit current.

This protection not only safeguards the device itself but also the connected pneumatic valves or other actuators. For example, in a pneumatic system, a short circuit in a solenoid valve could cause the cylinder to malfunction, affecting the entire production line. The short-circuit protection function can promptly cut off power during a short circuit, preventing further damage and ensuring system safety.

After the short-circuit fault is resolved, the device will automatically restore output functionality or can be restarted manually. It is recommended to carefully inspect the device's output terminals and connected external devices after each short-circuit incident to ensure the fault has been eliminated. Regularly checking the functionality of the short-circuit protection is also an important measure to ensure reliable device operation.

How to Optimize the Communication Performance?

Optimizing the communication performance of the EX600-SPR1A starts with ensuring the quality of the communication lines. Use high-quality shielded cables with proper grounding of the shield to minimize electromagnetic interference. Keep communication lines away from high-voltage power lines and other interference sources to avoid signal noise. Additionally, keep communication lines as short as possible to reduce signal attenuation.

When configuring communication parameters, select an appropriate communication speed based on actual application needs. Although the EX600-SPR1A supports up to 12 Mbps, lower speeds may suffice in some scenarios. Choosing the right speed can enhance communication stability and reduce errors. For example, in simple automation systems, a speed of 9.6 kbps may be adequate, while complex industrial networks may require higher speeds.

Ensure correct communication address and parameter settings to optimize performance. The device's communication address must match the master controller's settings to avoid conflicts. Regularly monitor the communication status using the device's LED indicators or the master controller's monitoring software. If communication anomalies are detected, promptly check the communication lines and device settings to ensure stable and reliable communication.

What is the Output Load Capacity?

The EX600-SPR1A is designed to drive SMC brand solenoid valves, with a maximum load capacity of 1.5 W per output point. This means the device can support various types of solenoid valves, including small and medium-sized pneumatic valves. When selecting solenoid valves, ensure their power does not exceed the device's maximum load capacity to prevent device damage.

The device's output type is PNP (sourcing, common negative), meaning the output current flows from the device to the solenoid valve. When designing the system, match the solenoid valve's current requirements with the device's output capabilities. For example, if the solenoid valve has a high current demand, select an appropriate power module to ensure sufficient current supply.

The device supports up to 32 output points, which can be configured according to actual needs. This allows simultaneous control of multiple solenoid valves or other actuators, enhancing system integration and flexibility. In practical applications, plan the system's load requirements and output capabilities carefully to ensure stable operation.

How to Set Parameters?

Parameters for the EX600-SPR1A can be set using the device's local operation panel or a master controller software. The local panel typically features simple buttons and LED indicators for setting basic parameters such as communication address and speed. When setting parameters, carefully consult the device's technical manual to ensure correct settings.

For more complex parameter settings, it is recommended to use master controller software. The software provides an intuitive interface and detailed configuration options. Users can set communication parameters, output configurations, and fault handling methods through the software. For example, users can configure the device's output behavior during communication faults, such as hold, clear, or force on.

After setting parameters, test the device to ensure normal operation. Run a simple test program to verify communication and output functionality. If errors are detected, adjust and retest the parameters. Additionally, regularly back up the device's parameter settings to prevent loss due to device failure or unexpected power outages.

What Are the Installation Options?

The EX600-SPR1A supports multiple installation methods to accommodate different application scenarios. Common installation options include panel mounting and base plate mounting. Panel mounting is suitable for installing the device on control cabinets or operation panels, offering easy access and maintenance. Base plate mounting is ideal for installing the device on equipment bases or frames, saving space and enhancing system integration.

When installing the device, ensure the location meets its environmental requirements. Install the device in a well-ventilated area free of dust and corrosive gases, and avoid high-temperature, high-humidity, or high electromagnetic interference zones. Ensure proper ventilation around the device to prevent overheating. For example, allow sufficient space around the device for air circulation.

Pay attention to power and communication line connections during installation. Use appropriate power cables and ensure correct connections. Use shielded cables for communication lines with proper grounding of the shield. After connections are made, test the device to ensure normal operation. Proper grounding of the device is also crucial for safe operation.

How to Perform Daily Maintenance?

Daily maintenance of the EX600-SPR1A primarily includes visual inspections, cooling system maintenance, and electrical connection checks. Regularly inspect the device's exterior for damage or loose screws. If the enclosure is damaged or poorly sealed, repair or replace it promptly to prevent dust and liquid ingress.

The cooling system is crucial for the device's normal operation. Regularly clean the cooling fans and heat sinks to ensure proper airflow. Dust or dirt on the heat sinks can reduce cooling efficiency and cause the device to overheat. Check the fans' operation and replace them if necessary to prevent device damage due to overheating.

Regularly inspect the integrity of power and communication line connections to ensure good contact. Repair or replace any loose or damaged lines. Additionally, regularly monitor the device's communication status and output functionality using LED indicators or master controller software. If any abnormalities are detected, promptly troubleshoot and address the issues to ensure stable device operation.

The above is a comprehensive introduction to the EX600-SPR1A and answers to common questions. We hope this information is helpful. If you have any other questions or require further technical support, please feel free to contact us.

FAQ

1.Who are We?

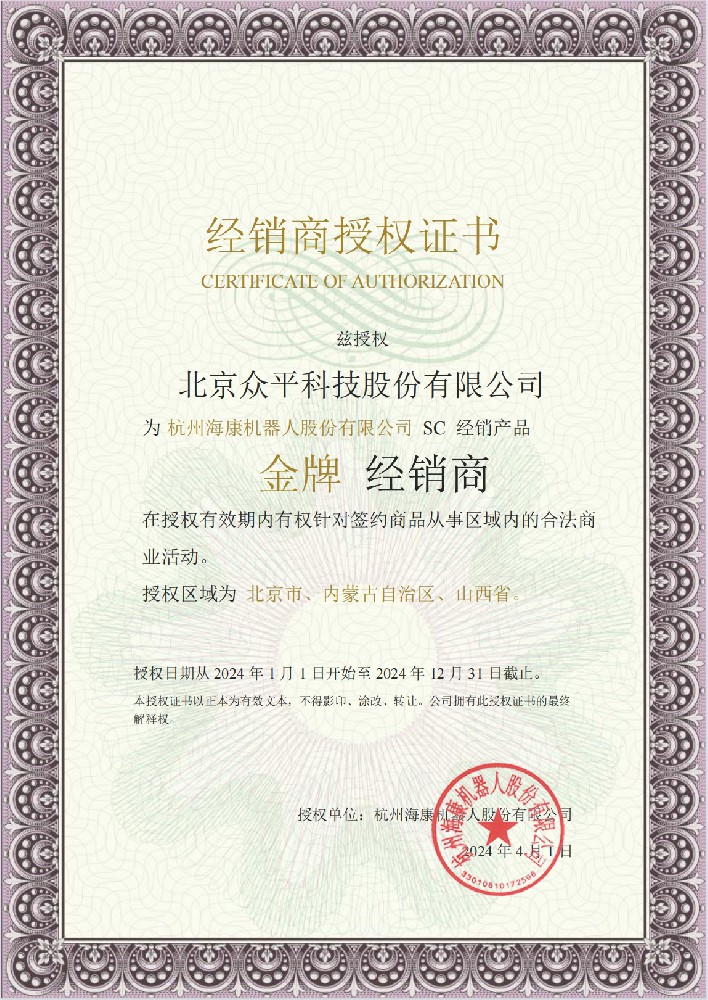

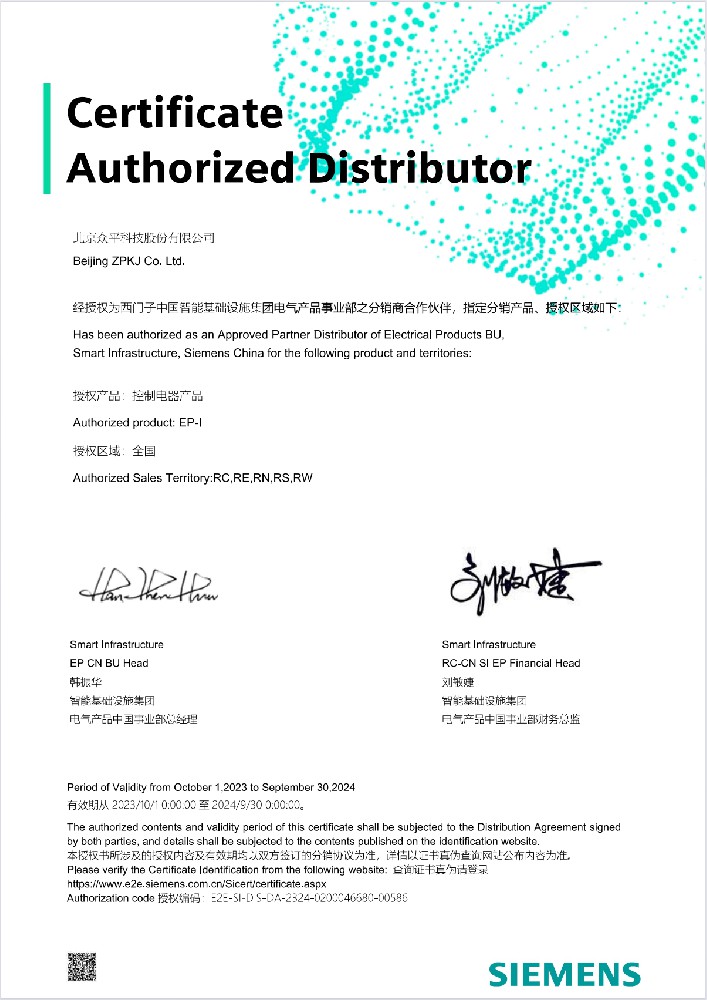

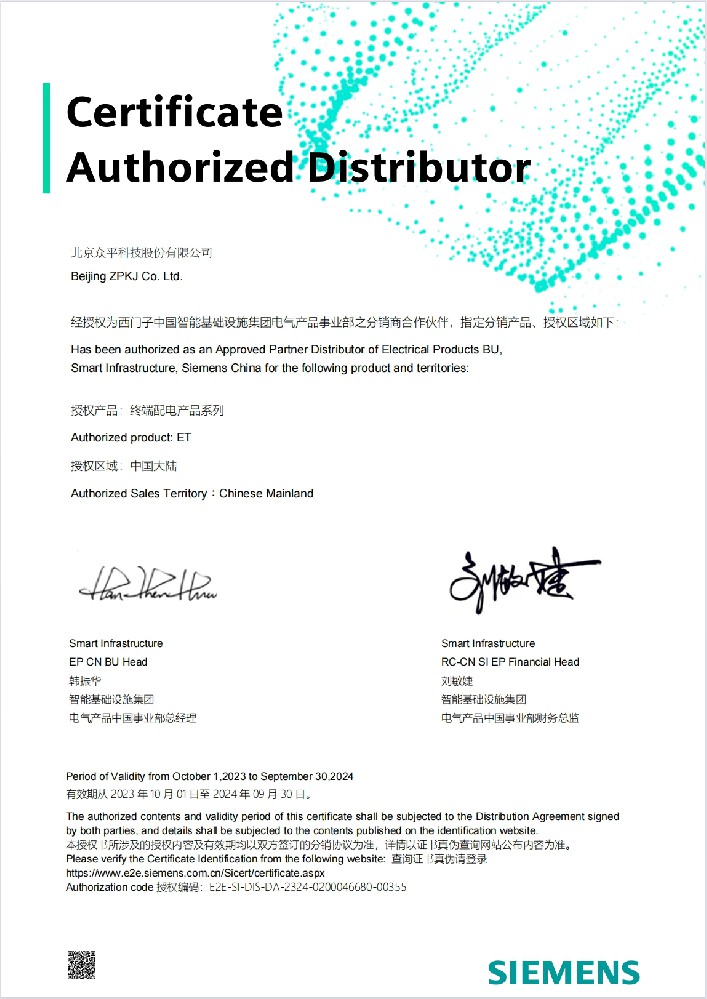

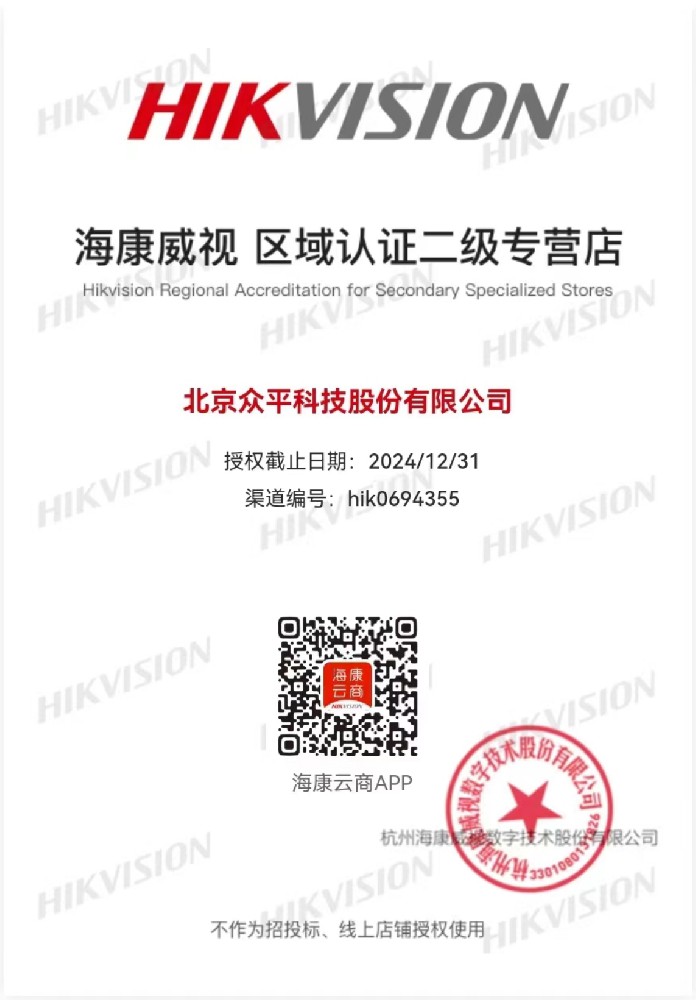

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China