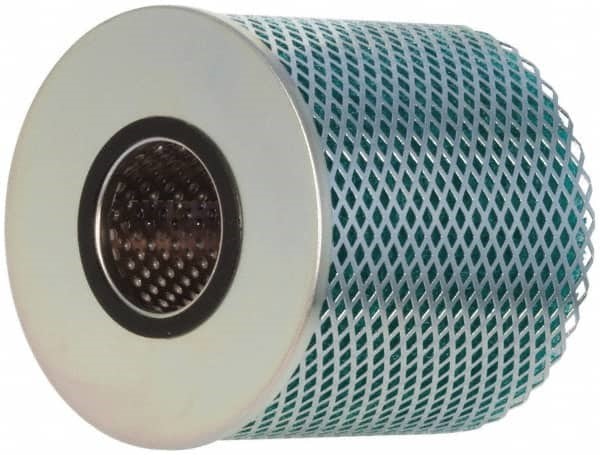

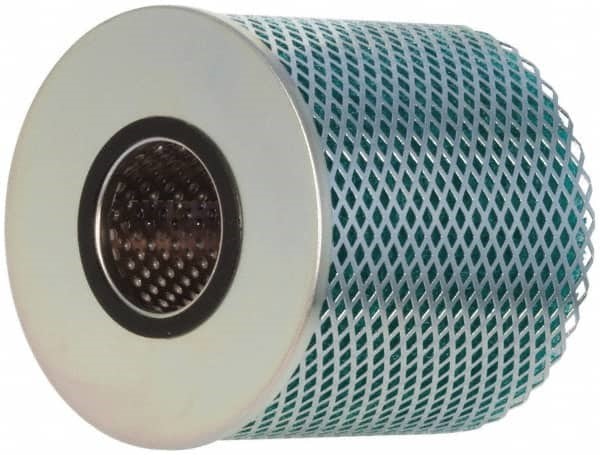

The AMC-EL6 smc filter produced by SMC Corporation, is a crucial component for exhaust smc regulator. It's widely used in industrial automation and smc controls system to ensure the efficient operation of pneumatic equipment and maintain a clean working environment. Product Introduction The AMC-EL6 smc filter is an essential part of the exhaust air purifier.

It is primarily used to remove oil mist and solid particles from compressed air, protecting pneumatic equipment from contamination, extending the life of the equipment, and ensuring the health of operators. This smc filter is suitable for various industrial environments, such as mechanical processing, automobile manufacturing, and electronic production.

Product Parameters

Model: AMC-EL6

Application: Exhaust air purifier

Function: Removes oil mist and solid particles from compressed air

Compatibility: Compatible with SMC's AMC-ZH series exhaust smc regulator and smc controls system

Product Features

High-efficiency filtration: The AMC-EL6 smc filter effectively removes oil mist and solid particles from compressed air, with a filtration efficiency of up to 99.9%.

Durable design: Made from high-quality materials, it ensures long-term stable operation in harsh industrial environments.

Easy replacement: The simple design allows for quick and easy replacement of the smc filter, reducing equipment downtime.

Application Scenarios

The AMC-EL6 smc filter is widely used in the following fields:

Mechanical processing: Used in machine tools, drilling machines, and other equipment to purify compressed air and protect pneumatic tools and equipment.

Automobile manufacturing: Used in automobile production lines to ensure the normal operation of pneumatic equipment, improving production efficiency and product quality.

Electronic production: Used in the electronic manufacturing process to purify compressed air and prevent oil mist and particle contamination of electronic components.

Usage Instructions

Installation and Wiring

Installation environment: Choose a well-ventilated, dust-free, and non-corrosive gas environment for installation. Avoid installing the smc filter in high-temperature, high-humidity, or strong electromagnetic interference environments.

Installation method: Ensure the smc filter is installed vertically to facilitate air circulation. Use appropriate fixing methods during installation to prevent vibration from affecting the equipment.

Parameter Settings

Basic parameter settings: Set the replacement cycle and maintenance reminders for the smc filter according to actual application requirements.

Advanced feature configuration: For example, set the automatic cleaning function to extend the life of the smc filter.

Maintenance and Inspection

Regular inspection: Check the appearance of the smc filter for damage or dust accumulation. Regularly clean the dust on the smc filter to ensure the smooth operation of the filtration system.

Parameter verification: Regularly verify the filtration efficiency of the smc filter to ensure it meets the actual application requirements.

Fault diagnosis: When the equipment fails, promptly check the fault code and troubleshoot according to the fault diagnosis guide in the manual.

Precautions

Environmental conditions: Avoid using the product in high-temperature, high-humidity, or strong electromagnetic interference environments to prevent affecting its performance and lifespan.

Power requirements: Ensure the power voltage is stable to prevent damage to the equipment from voltage fluctuations. After the equipment is powered off, wait for a certain period before powering it on again to avoid damaging the equipment.

Safe operation: Avoid contact with live parts during equipment operation to ensure the safety of operators. When performing maintenance and inspection, the power must be cut off, and the capacitor must be fully discharged.

Frequently Asked Questions (FAQ)

1. How to replace the AMC-EL6 smc filter?

Replacement steps: To replace the AMC-EL6 smc filter, first, turn off the power supply of the equipment to ensure it is completely stopped. Then, open the smc filter replacement port of the equipment, remove the old smc filter, install the new AMC-EL6 smc filter, and ensure it is securely installed.

Replacement cycle: It is recommended to replace the smc filter regularly based on the usage frequency and environmental conditions of the equipment. Generally, the smc filter should be replaced every 6 months to ensure filtration effectiveness.

Maintenance suggestions: While replacing the smc filter, inspect other components of the equipment, such as pipes and valves, to ensure the normal operation of the entire system.

2. What is the filtration efficiency of the AMC-EL6 smc filter?

Filtration efficiency: The AMC-EL6 smc filter has a filtration efficiency of up to 99.9%, effectively removing oil mist and solid particles from compressed air.

Testing methods: The filtration efficiency is typically tested using standard particle counters and oil mist detectors. The efficiency is calculated by comparing air samples before and after filtration.

Practical application: In practical applications, the AMC-EL6 smc filter can significantly reduce equipment failure rates, extend the lifespan of the equipment, and improve production efficiency.

3. How to ensure the correct installation of the AMC-EL6 smc filter?

Installation steps: Ensure the smc filter is installed in the correct direction, usually indicated by an arrow on the smc filter showing the airflow direction. Insert the smc filter into the smc filter slot of the equipment and ensure a good seal between the smc filter and the equipment.

Inspection methods: After installation, start the equipment and check for any air leaks from the smc filter. If air leaks are detected, reinstall the smc filter to ensure a good seal.

Maintenance suggestions: Regularly inspect the installation of the smc filter to ensure it is not loose or damaged. If damage is found, replace the smc filter promptly.

4. What is the maintenance cycle for the AMC-EL6 smc filter?

Maintenance cycle: It is recommended to perform a maintenance check on the smc filter every 3 months, including inspecting the appearance and cleaning the dust on the smc filter.

Maintenance content: During maintenance, check the filtration efficiency of the smc filter. If a decrease in filtration efficiency is observed, replace the smc filter promptly.

Maintenance records: It is suggested to keep records of each maintenance session, including the time and content, to track the usage and maintenance cycle of the smc filter.

5. How to choose the right AMC-EL6 smc filter?

Application requirements: Select the appropriate smc filter based on the specific application requirements of the equipment. If the equipment has high air quality requirements, choose a high-efficiency filtration smc filter.

Environmental conditions: Consider the usage environment of the equipment, such as temperature, humidity, and dust concentration. In harsh environments, choose a smc filter that is resistant to high temperatures and corrosion.

Cost-effectiveness: Consider the price and lifespan of the smc filter to choose a cost-effective option. Although high-efficiency smc filters may be more expensive, their longer lifespan can reduce replacement frequency and overall costs.

6. What is the compatibility of the AMC-EL6 smc filter?

Compatible equipment: The AMC-EL6 smc filter is compatible with SMC's AMC-ZH series exhaust smc regulator.

Installation method: The installation of the smc filter is simple and can be directly inserted into the smc filter slot of the equipment without the need for complex installation tools.

Maintenance suggestions: When installing the smc filter, ensure that other components of the equipment are also in good condition to ensure the normal operation of the entire system.

7. How to handle faults of the AMC-EL6 smc filter?

Fault diagnosis: When the equipment fails, first check if the smc filter is damaged or blocked. If the smc filter is damaged, replace it promptly.

Fault codes: The equipment usually displays fault codes, which can quickly locate the problem. Common fault codes include smc filter blockage and decreased filtration efficiency.

Maintenance suggestions: When handling faults, it is recommended to refer to the equipment's user manual and follow the steps in the manual. If the problem cannot be solved, contact the equipment manufacturer or professional maintenance personnel.

8. What is the lifespan of the AMC-EL6 smc filter?

Lifespan: The lifespan of the AMC-EL6 smc filter is typically 6 months to 1 year, depending on the usage frequency and environmental conditions of the equipment.

Influencing factors: The lifespan of the smc filter is affected by various factors, such as the concentration of particles in the air and the operating time of the equipment. In high-pollution environments, the lifespan of the smc filter will be shortened.

Maintenance suggestions: Regularly check the filtration efficiency of the smc filter. If a decrease in filtration efficiency is observed, replace the smc filter promptly.

9. How to choose the installation location for the AMC-EL6 smc filter?

Installation location: The smc filter should be installed at the air inlet of the equipment to ensure that the air is filtered by the smc filter before entering the equipment.

Environmental requirements: The installation location should be well-ventilated, dust-free, and free of corrosive gases. Avoid installing the smc filter in high-temperature, high-humidity, or strong electromagnetic interference environments.

Maintenance suggestions: When installing the smc filter, ensure that other components of the equipment are also in good condition to ensure the normal operation of the entire system.

10. What is the cleaning method for the AMC-EL6 smc filter?

Cleaning steps: To clean the smc filter, first, turn off the power supply of the equipment to ensure it is completely stopped. Then, remove the smc filter and gently clean the dust on it using compressed air or a soft brush.

Cleaning frequency: It is recommended to clean the smc filter every 3 months, with the specific frequency depending on the usage environment and frequency of the equipment.

Maintenance suggestions: When cleaning the smc filter, avoid using water or chemical solvents to prevent damage to the smc filter. If the smc filter is damaged, replace it promptly.

FAQ

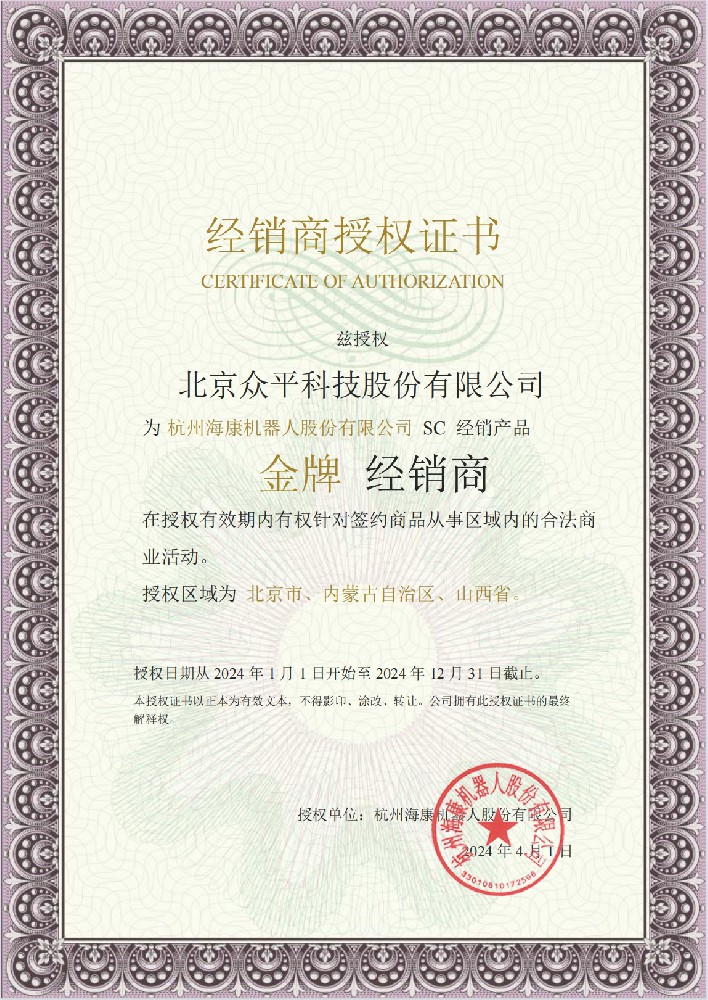

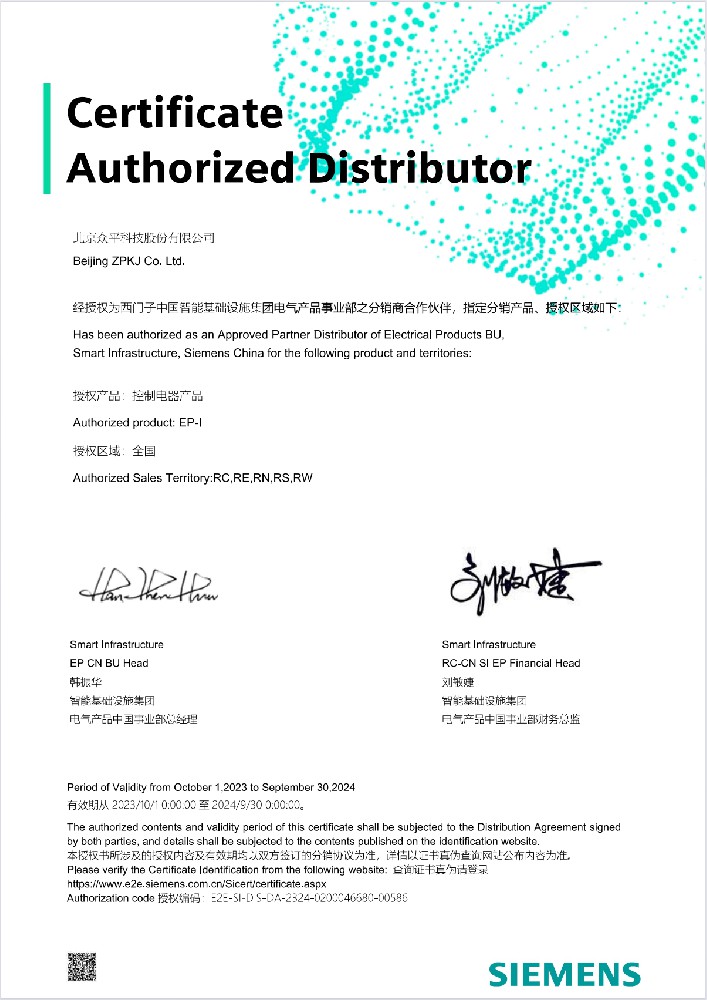

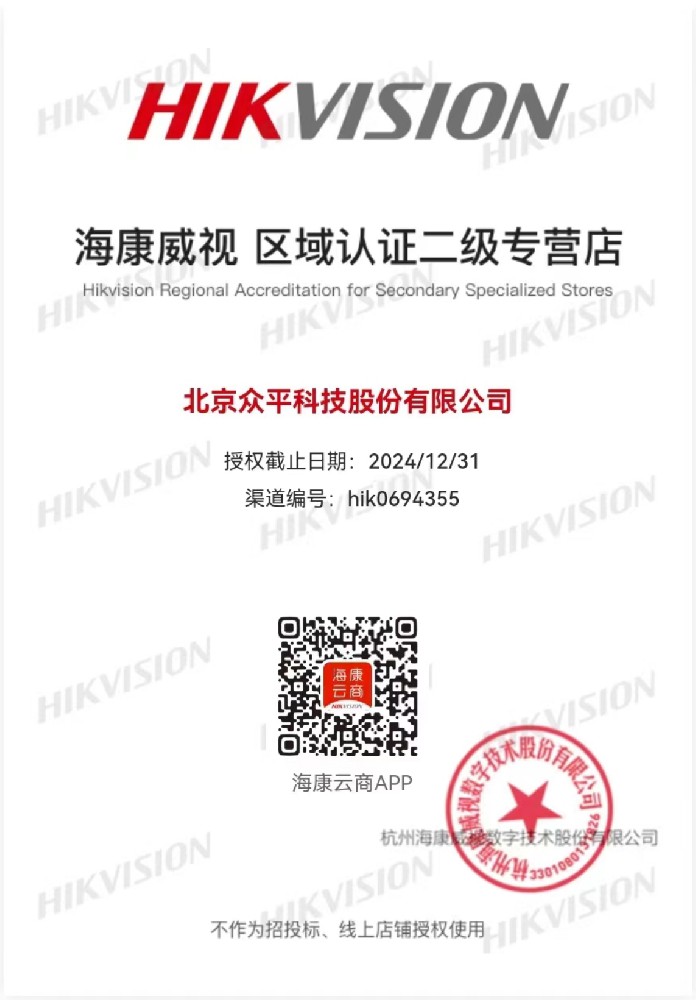

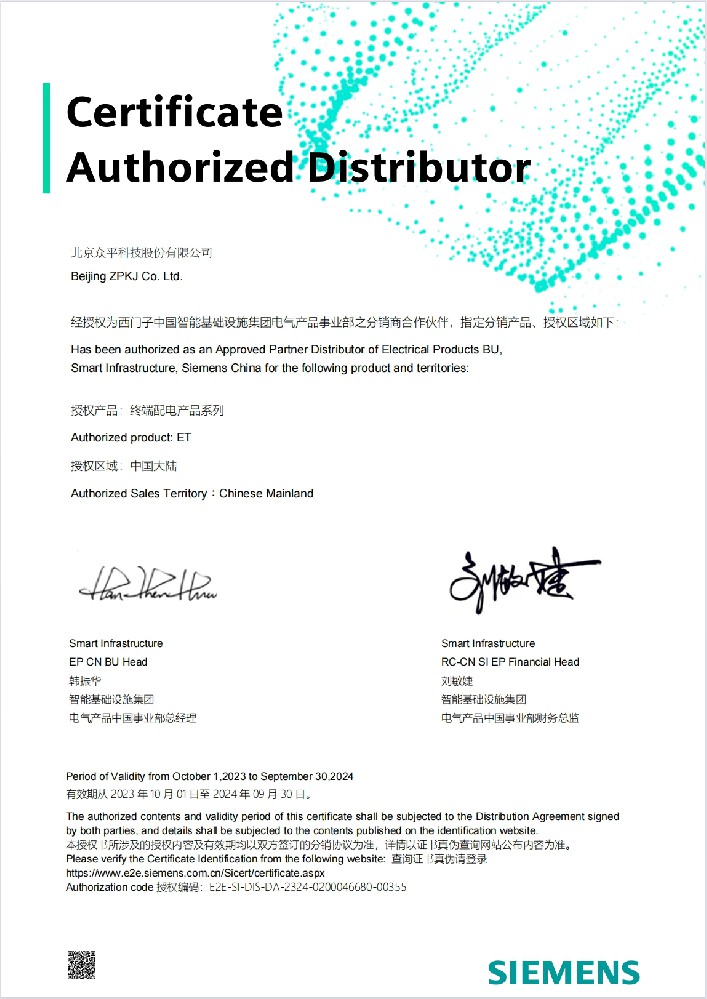

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China