LS PLC use introduction

Published:2023-07-07 09:26:54

1, for switching quantity control

The ability of PLC to control the switching quantity is very strong. The number of points controlled by the input and output points, as few as a dozen points, dozens of points, many hundreds, thousands, and even tens of thousands of points, because it can be networked, the number of points is almost unlimited, no matter how many points can be controlled, the logic problem can be so diverse: Combined, sequential, immediate, delay, no counting, demand counting, fixed order, random operations, etc., can be carried out.

The hardware structure of PLC is variable, and the software program is programmable, which is very flexible when used for control. If necessary, multiple sets or groups of programs can be written and called according to demand. It is very suitable for the needs of multi-condition and multi-condition change in industrial site. There are many examples of switching quantity control with PLC, metallurgy, machinery, light industry, chemical industry, textile, etc., almost all industrial occupations need to use it. Now, the first goal of the PLC, and other controllers can not be compared with it, is that it can be easily and reliably used for switching control.

2, for analog control

Analog quantity, such as current, voltage, temperature, pressure, etc., its size is continuously changed. Industrial production, especially continuous production processes, often requires the manipulation of these physical quantities. As an industrial control electronic equipment, if the PLC can not control these quantities, it is a major deficiency, for which the PLC manufacturers have carried out a lot of development in this regard. Now, not only large and medium-sized machines can carry out analog control, but also minicomputers can carry out such control.

3, for motor control

Practical physical quantities, in addition to switching quantities, analog quantities, and motion control. For example, the displacement of machine tool components is often expressed in digital quantities. For motor control, the effective method is NC, that is, digital control skills. This was born in the United States in the 1950s based on computer manipulation skills. Today it is very popular and very well developed. Now, the ratio of metal cutting machine tools in advanced countries has exceeded 40%-80%, and some are even higher. PLC is also based on computer skills, and increasingly perfect. PLC can accept counting pulses, the frequency can be as high as a few k to tens of k Hertz, can be used in a variety of ways to accept this pulse, but also multiple acceptance. Some PLC also has pulse output function, pulse frequency can also reach tens of k, with these two functions, coupled with PLC data processing and computing ability, if equipped with the corresponding sensor (such as rotary encoder) or pulse servo equipment, you can completely complete various operations according to the principle of NC.

4. Used for data collection

With the development of PLC skills, its data storage area is getting larger and larger. For example, the PLC of Devison Company, its data storage area (DM area) can reach 9999 words. Such a large data storage area can store a large amount of data. The data acquisition can use a counter to accumulate the number of pulses collected and transfer them to the DM area on time. Data acquisition can also be used as A/D unit, when the analog quantity is converted into a digital quantity, and then transferred to the DM area on time. PLC can also be equipped with a small printer to regularly type out the data in the DM area. PLC can also communicate with the computer, the data in the DM area is read out by the computer, and the data is processed by the computer. At this time, the PLC becomes the data terminal of the computer. Power users have used LS power generation PLC to record the user's power consumption in real time, in order to complete the charging method of different electricity consumption times and different pricing, and encourage users to use more electricity when the electricity is low, to achieve the purpose of reasonable electricity consumption and saving electricity.

5, for signal monitoring

There are many PLC self-test signals and many internal devices, and most users do not give full play to their effects. In fact, it can be fully used to monitor the operation of the PLC itself, or to monitor the control target. For a complex control system, especially automatic control system, monitoring and further self-diagnosis is very necessary, it can reduce the failure of the system, the fault is also found, can improve the cumulative uniform trouble-free operation time, reduce the fault correction time, improve the reliability of the system.

6, for networking, communication

PLC networking, communication ability is strong, and there are constantly new networking structures introduced. PLC can be connected with a personal computer for communication, and the computer can participate in programming and control the PLC, so that the PLC is more convenient to use. In order to give full play to the effect of the computer, a computer can be implemented to control and handle multiple PLCS, up to 32. An LS power generation PLC can also communicate with two or more computers to exchange information to complete the monitoring of the PLC control system. PLC and PLC can also communicate, can be one-to-one PLC communication, can be several PLC communication, can be dozens, hundreds.

-

202212-30

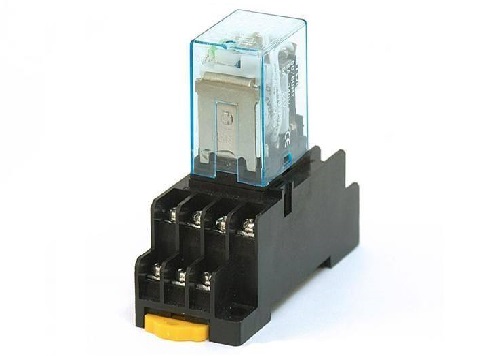

202212-30Nine main characteristics of Omron relays

1. Extremely small and lightweight typeOmron relay has developed and manufactured an extra small standard, the first relay profession at home and abroad, occupies a leading position in the market.2, l···

-

202302-17

202302-17959698 reasons for failure of Siemens 3RW44 soft starter

3RW44 Soft starter 95,96,98 is a comprehensive fault, what causes it to operate?95,96,98 reasons for failure of Siemens 3RW44 soft starter95,96,98 is the normally open normally closed integrated fault···

-

202212-29

202212-29What symptom can WEINVIEW touch screen motherboard malfunction appear?

1. The motherboard cannot recognize/display peripheral devices.2. Peripherals will stop working for a few seconds or more.3. A slow startup may indicate that your motherboard is broken, although it co···

-

202303-02

202303-02Mitsubishi servo motors one-button adjustment function

When different servo motors are installed on the machine for the first time, they will occasionally show a poor match with the machinery during operation, which will lead to vibration, noise and other···

-

202302-22

202302-22ABB robot model explanation and composition

IRB type robot is the famous Swedish robot life manufacturer ABB company,IRB refers to ABB standard series of robots. IRB robots are often used for welding, brushing, handling and cutting. Commonly us···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China