The SMC Pneumatics E5050 is one of the high-performance pneumatic fittings widely used in the field of industrial automation.

It features high-precision control, reliability, and ease of use. This pneumatic cylinder is suitable for a variety of industrial scenarios, such as mechanical automation, material handling, and automated production lines. By providing precise pneumatic control, the SMC Pneumatics E5050 ensures efficient and stable operation of equipment.

Product Specifications:

Fluid Type: Air.

Pressure Range: Guaranteed pressure resistance of 1.5 MPa, with a maximum operating pressure of 1.0 MPa and a minimum operating pressure of 0.05 MPa.

Ambient Temperature: -10°C to +70°C (when equipped with an internal magnet, the range is -10°C to +60°C).

Operation Mode: Double-acting.

Speed Range: Piston speed ranges from 50 to 1000 mm/sec for sizes φ20 to φ63, and 50 to 700 mm/sec for sizes φ80 and φ100.

Buffer Options: Cushion or air buffer.

Product Features:

Oil-Free Design: The SMC Pneumatics E5050 is an oil-free cylinder, eliminating the need for additional lubrication during use. However, an oil mist lubricator can be installed if lubrication is required.

High-Precision Control: With built-in speed control valves, this pneumatic cylinder offers precise speed control, supporting both inlet throttling and exhaust throttling.

Safety and Reliability: The product meets industrial standards, featuring excellent sealing and corrosion resistance, making it suitable for various industrial environments.

Easy Installation and Maintenance: The simple design allows for easy installation and provides detailed maintenance guidelines to ensure long-term stable operation.

Applications:

Automated Production Lines: Used for material handling and robotic arm control, ensuring efficient and stable production processes.

Food Processing Industry: Operates in clean, oil-free environments to control pneumatic cylinder movements, ensuring food safety.

Automotive Manufacturing: Used for pneumatic control in component assembly and inspection equipment.

Electronics Manufacturing: Achieves high-precision pneumatic control during the assembly and inspection of electronic components.

Installation and Wiring:

Installation Environment: Select a dust-free, non-corrosive, and low-electromagnetic interference environment, ensuring good heat dissipation for the equipment.

Wiring Requirements: Follow the wiring diagram in the product manual strictly to ensure correct connections for power, signal, and air lines.

Grounding Protection: Ensure proper grounding of the equipment in accordance with national and local electrical safety regulations.

Parameter Settings:

Basic Settings: Adjust cylinder speed, buffer options, etc., based on actual application needs.

Advanced Configuration: Features like multi-speed control and PID control can be configured for specific application scenarios.

Maintenance and Inspection:

Regular Inspection: Check the pneumatic cylinder for damage, aging seals, and piston rod wear.

Cleaning and Lubrication: Regularly clean the cylinder surface of dust and dirt to ensure cleanliness and proper lubrication.

Fault Diagnosis: When a fault occurs, refer to the troubleshooting guide in the manual to identify and resolve the issue based on the fault code.

Precautions:

Environmental Conditions: Avoid using these pneumatic fittings in high-temperature, high-humidity, or strong electromagnetic interference environments to prevent performance degradation and reduced lifespan.

Air Quality: Ensure the supplied compressed air is clean and dry, free from chemicals or oil content.

Safe Operation: Avoid contact with live parts or moving components during operation to ensure operator safety.

Maintenance: Regularly inspect seals and connections to ensure proper equipment operation.

Common Questions and Answers (FAQ):

How to Adjust the Speed of the SMC Pneumatics E5050 Cylinder?

The speed of the SMC Pneumatics E5050 cylinder can be controlled by adjusting the inlet and exhaust throttling valves.

Inlet Throttling: Adjust the throttling valve at the inlet to control the airflow into the cylinder. Increasing the airflow speeds up the cylinder’s movement; while reducing it slows it down.

Exhaust Throttling: This is a commonly used method. By controlling the exhaust airflow, you can adjust the cylinder's retraction speed. It offers a wide and stable adjustment range.

Note: When adjusting speed, ensure the cylinder's load is within the allowable range to avoid shocks or inefficient operation.

Does the SMC Pneumatics E5050 Require Lubrication?

The SMC Pneumatics E5050 is an oil-free cylinder and does not require additional lubrication during normal use. However, if enhanced lubrication is needed, an oil mist lubricator can be installed using ISO VG-32 turbine oil (unadulterated). Once lubrication begins, continuous oil supply must be maintained.

What is the Operating Temperature Range of the SMC Pneumatics E5050?

The SMC Pneumatics E5050 operates within a temperature range of -10°C to +70°C. If equipped with an internal magnet, the range is -10°C to +60°C. Be cautious of burns when operating in high-temperature environments.

What is the Pressure Range of the SMC Pneumatics E5050?

The SMC Pneumatics E5050 has a guaranteed pressure resistance of 1.5 MPa, with a maximum operating pressure of 1.0 MPa and a minimum operating pressure of 0.05 MPa. Ensure the working pressure does not exceed the maximum operating pressure of these pneumatic fittings to prevent equipment damage.

How to Resolve Slow Movement of the SMC Pneumatics E5050 Cylinder?

If the SMC Pneumatics E5050 cylinder moves slowly, try the following:

Check if the air pressure is too low and ensure it remains within the 0.05 MPa to 1.0 MPa range.

Adjust the inlet or exhaust throttling valve to increase airflow.

Inspect the cylinder for internal debris or blockages and clean if necessary.

Does the SMC Pneumatics E5050 Support Buffer Functions?

Yes, the SMC Pneumatics E5050 supports buffer functions, including cushion and air buffer. By adjusting the buffer mechanism, you can control the cylinder's start and stop speeds, reducing shocks and extending equipment life.

What are the Installation Environment Requirements for the SMC Pneumatics E5050?

Install the SMC Pneumatics E5050 in a dust-free, non-corrosive, and low-electromagnetic interference environment. Ensure good heat dissipation and avoid high-temperature, high-humidity, or poorly ventilated areas.

What is the Maintenance Cycle for the SMC Pneumatics E5050?

Regularly inspect the appearance, seals, and piston rod wear of the SMC Pneumatics E5050. Perform a visual inspection monthly and a comprehensive maintenance check quarterly, including dust removal, seal inspection, and lubrication.

Does the SMC Pneumatics E5050 Support Multi-Speed Control?

The SMC Pneumatics E5050 can achieve multi-speed control through external control devices. Users can configure different speed segments based on specific process requirements.

What is the Electromagnetic Compatibility of the SMC Pneumatics E5050?

The SMC Pneumatics E5050 complies with relevant electromagnetic compatibility standards. During installation, ensure signal and power lines are separated, use shielded cables, and maintain proper grounding to minimize electromagnetic interference.

FAQ

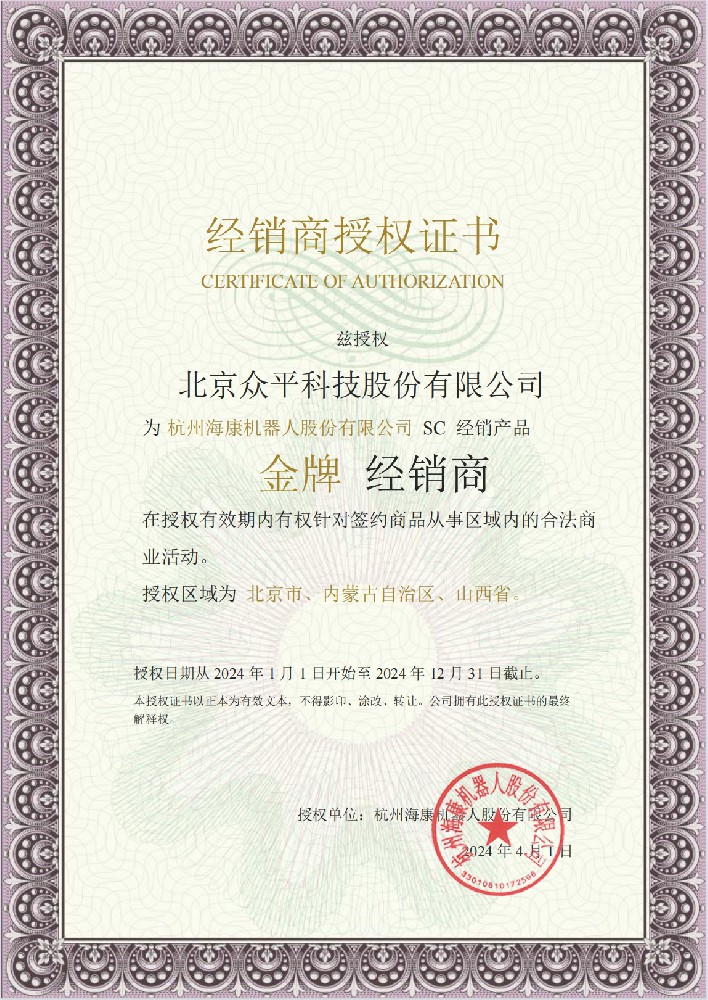

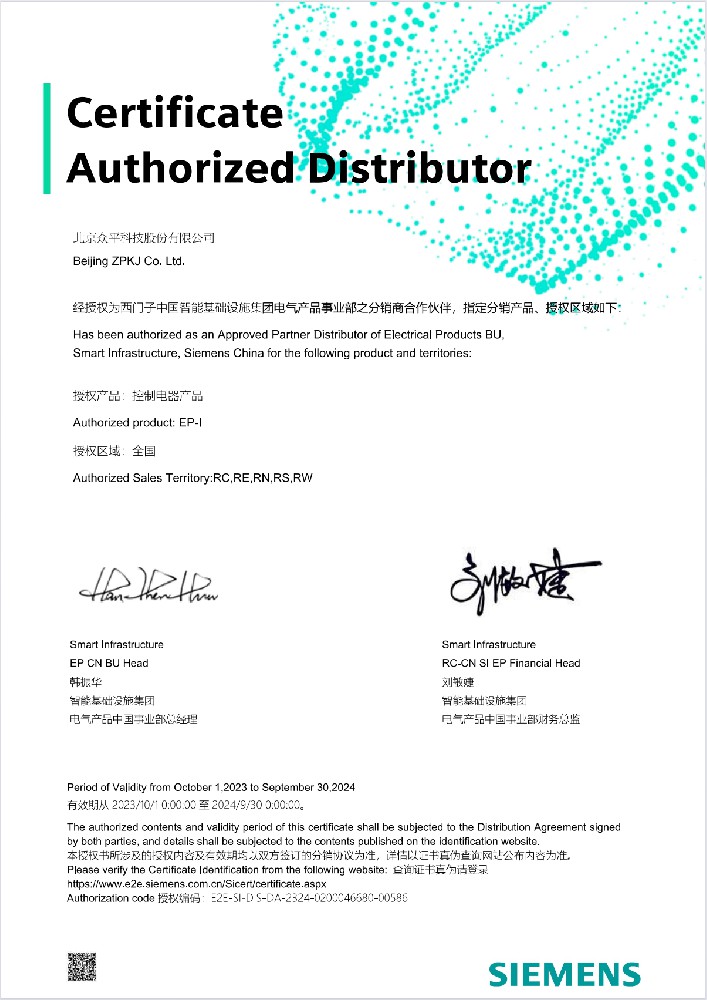

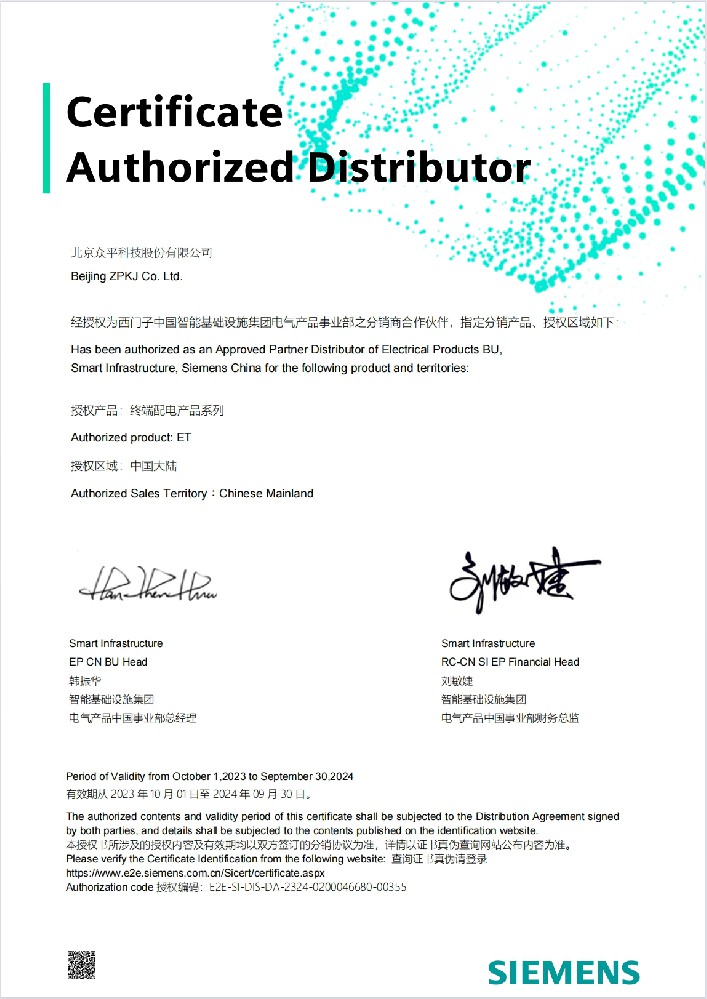

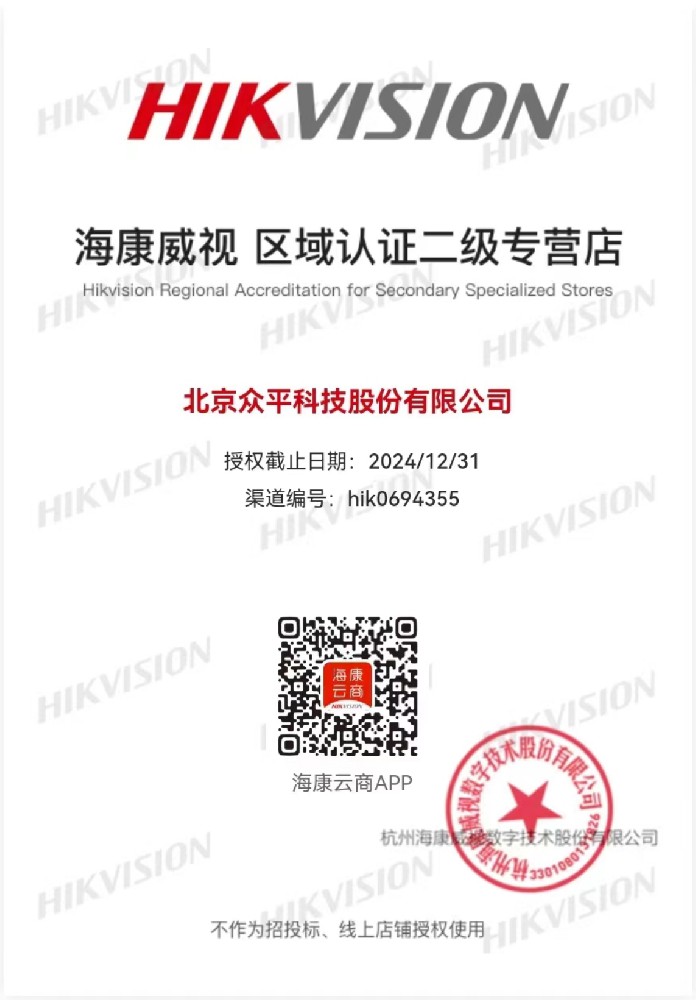

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China