ABB breaker failure and treatment

Published:2022-12-30 11:22:31

Judgment and handling of "reject" failure

The occurrence of "rejection" situation, basically in the closing operation and reclosing process. This kind of failure is very harmful. For example, if the circuit breaker of the standby power supply refuses to close when the emergency input of the standby power supply is required in the case of an accident, the accident will be amplified. There are three steps to determine the cause and treatment of circuit breaker rejection.

1) Check whether the previous refusal to close is caused by improper operation (such as the control switch to let go too fast, etc.), and use the control switch to re-integrate.

2) If the closing still fails, check all parts of the electrical circuit to determine whether there is a fault in the electrical circuit. Check items are: closing control power supply is normal; Whether the closing control circuit fuse and closing circuit fuse are good; Whether the contact of the closing contactor is normal; The control switch to the "closing" position, to see whether the closing core action is normal.

3) If the electrical circuit is normal and the circuit breaker still cannot be closed, it indicates that it is a mechanical fault. The circuit breaker should be stopped and the dispatch arrangement maintenance treatment should be reported.

After the above preliminary inspection, can determine is electrical, or mechanical failure. Common electrical circuit failures and mechanical failures are described below.

1. Common electrical faults

If the red and green lights are not on before the closing operation, it indicates that there is no control power supply or the control loop is disconnected. It can check whether the components of the control power supply and the whole control circuit are normal, such as: whether the operating voltage is normal, whether the fuse is blown, whether the anti-jump relay is normal, whether the auxiliary contact of the circuit breaker is good.

When the green light flashes after the operation of closing, and the red light is not on, the instrument has no indication, the horn sounds, the breaker mechanical division, closing position indicator is still in the opening position, it indicates that the operation handle position and the position of the circuit breaker does not correspond, the circuit breaker is not closed. The common reasons are: the closing circuit fuse is blown or poor contact; Closing contactor does not operate; The closing coil is faulty.

When the circuit breaker is closed, the green light is out, the red light is bright and then out, the green light is flashing and the horn is ringing, indicating that the circuit breaker is automatically tripped after closing. The reason may be that the circuit breaker is closed on the faulty line, causing the protective action trip or the circuit breaker mechanical failure can not keep the circuit breaker in the closed state.

If the green light flashes or goes off after the operation is closed, the red light is not on, but the table has indications, the mechanical opening and closing position indicator is in the closing position, indicating that the circuit breaker has been on. The possible cause is the circuit breaker auxiliary contact is poor, such as normally closed contact is not disconnected, normally open contact is not closed, resulting in the green flash and red light is not on; It may also be the closing circuit broken or the closing red light burned out.

Operator handle back too early.

The operating voltage is too low. The voltage is below 80% of the rated voltage.

2. Common mechanical failures

1) The connecting rod of the transmission mechanism is loose and falls off.

2) The closing iron core is stuck astringent.

3) The mechanism does not return to the pre-closing position after the breaker is turned off.

4) Trip mechanism trip.

5) The action voltage of the closing electromagnet is too high, so that the hook fails to hang.

6) The opening connecting rod does not return.

7) The mechanism is stuck, the connecting part of the shaft pin falls off, so that the mechanism is hollow closed.

8) Sometimes when the circuit breaker is closed for several consecutive times, the auxiliary normal closing contact of the switch is opened too early.

Judgment and treatment of "rejection" fault

The "rejection" of the circuit breaker is a great threat to the safe operation of the system. When the equipment fails, the circuit breaker is rejected, which will cause the electrical equipment to burn out or skip the step and cause the power circuit breaker to trip, so that the bus voltage of the transformer and distribution office disappears, resulting in a large area of power outage. The solution to the "score rejection" fault is as follows:

According to the accident phenomenon, determine whether the circuit breaker "reject" accident. When there is a total swing of the meter, the voltmeter indicating value significantly reduced, circuit light word plate bright, signal drop card show protective action, it indicates that the circuit breaker refuses to open.

When the circuit breaker is determined to be faulty, manually switch it off immediately. When the ammeter indicating value of the main transformer power circuit breaker meets the threshold and the abnormal sound is strong before the fault circuit breaker is determined, the power circuit breaker should be opened first to prevent burning the main transformer. When the superior backup protection action causes power failure, if it is found that there is shunt protection action and the circuit breaker does not trip, the circuit breaker that refuses to operate should be opened to restore the superior power circuit breaker; If it is found that all the branch switches are not in action (may also be protection reject card), check that there is no fault in the power outage range. If there is no fault, open all the branch circuit breakers, close the power circuit breaker, and try to send each branch circuit breaker one by one. When the power circuit breaker trips again to a branch, the circuit breaker can be identified as a fault (" reject ") circuit breaker. This circuit breaker should not be sent again, but the other circuits should be restored to power.

In the inspection of the "reject" circuit breaker in addition to the general electrical fault that can be quickly eliminated (such as control power supply voltage is too low, or control circuit fuse contact is bad, fuse blown, etc.), for a time difficult to deal with electrical or mechanical faults, should contact the dispatch, as a stop, repair treatment. The method of analyzing and judging the "rejection" fault of the circuit breaker is as follows:

1. Check whether the voltage of the tripping power supply is too low.

2. Check whether the trip circuit is intact. If the trip core works well and the circuit breaker rejects points, it indicates a mechanical fault.

3. If the power supply is good, if the core action is weak, the core card is astringent or the coil fault causes the rejection, it may be electrical and mechanical faults.

4, if the operating voltage is normal, the iron core does not move after the operation, it is likely to be electrical fault caused by "reject". Common electrical and mechanical failures are:

· Electrical reasons include: the fuse of the control loop is fused or the components of the tripping loop, such as the contact of the control switch, the auxiliary contact of the operating mechanism of the circuit breaker, the anti-tripping relay and the tripping circuit of the relay protection are in poor contact; Tripping circuit break or tripping coil burned out; The setting value of relay protection is incorrect; The DC voltage is lower than 80% of the rated voltage. Procedure

· Mechanical reasons include: insufficient impact force of tripping iron core, indicating that the iron core may get stuck or fall off; Contact welding or mechanical sticking, transmission part failure (such as pin fall off, etc.).

Diagnose and deal with the "misallocation" fault

If the circuit breaker trips automatically and the relay protection does not operate, and there is no short circuit or other abnormal phenomenon in the system during the trip, the circuit breaker is "misassigned". The judgment and treatment of "misclassification" are generally divided into the following three steps.

1, according to the characteristics of the accident phenomenon, that is, before the circuit breaker trip meter, signal indication is normal, trip, green light continuous flash, red light out, the circuit breaker ammeter and active power, reactive power meter indication is zero, it can be determined to be "wrong".

2, check whether it is due to personnel by mistake, misoperation, or caused by external mechanical vibration of the "wrong", at this time should eliminate the cause of the switch fault, immediately power.

3, if the electrical or mechanical part of the fault and can not be immediately power, should contact the dispatch will be "wrong" circuit breaker stop for maintenance processing. Common electrical and mechanical failures are:

Electrical faults include: protective misaction or improper setting, or current, voltage transformer circuit fault; The secondary circuit insulation is poor, DC system is grounded at two points, so that the DC positive and negative power is connected, which is equivalent to the relay protection action, resulting in signal tripping.

Mechanical faults include: trip trip mechanism cannot be maintained; Positioning screw adjustment is improper, so that the three points of the arm is too high; Trailer spring deformation, insufficient elasticity; Roller damage; The slope of the trailer is large, the roller is not straight or the contact surface on the trailer is less.

Judgment and treatment of "misalignment" fault

If the circuit breaker automatically closes without operation, it is a "misalignment" fault. Generally, the following methods should be used to judge the treatment. It is confirmed by inspection that the operation is not closed. If the handle is in the "after" position and the red light is flashing continuously, it indicates that the circuit breaker is closed, but it is "misclosed". The mismatched circuit breaker should be opened at this time.

For the "mis-closing" circuit breaker, if the circuit breaker is "mis-closing" again after opening, should take off the closing fuse, respectively check the electrical and mechanical reasons, contact the dispatch will stop the circuit breaker for maintenance treatment. The reasons for this "misfit" may include:

1. The positive and negative two points in the DC circuit are grounded, so that the closing control circuit is connected.

2, automatic reclosing relay in a component fault through the control loop (such as internal time relay normally open contact closed by mistake), so that the circuit breaker closed.

3, closing contactor coil resistance is too small, and the starting voltage is low, when the DC system instantaneous pulse, will cause the circuit breaker to misclose.

-

202306-30

202306-30Advantech motherboard how to enter the U disk starter

If you can access the operating system before reinstalling the industrial computer system, you should back up important data and drivers to avoid the loss of important files due to system reinstallati···

-

202301-28

202301-28Siemens SINAMICS GM150 Deep Maintenance

On-site maintenanceCheck and clean pre-charge loop, rectifier unit, diode characteristics, inverter unit, GSV, AVT.Rectifier module diagnostic test, and high voltage switchgear interface function test···

-

202302-23

202302-23The solution of Schneider inverter fault code

PHF: ⒈ Frequency converter power supply is not correct or fuse is blown; B. There is momentary defect in some phase. ⒈ Check the power supply connection and fuse; B. Reposition.USF: ⒈ Supply voltag···

-

202212-29

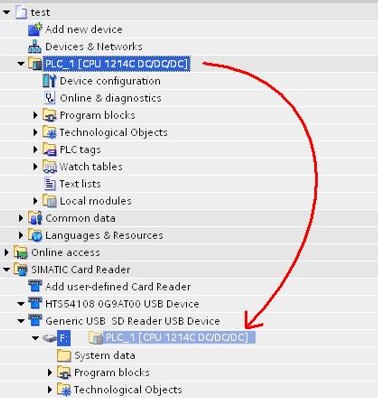

202212-29Siemens loads items into a memory card in transfer mode

Loads items to a memory card in transfer modeStep 1: Set the memory card to "transfer card" mode according to the above method. You are advised to clear all files from the memory card before···

-

202305-26

202305-26Siemens s7-200 SMART Interrupt instruction

S7-200 SMART series programmable controller ** has 38 interrupt sources (9 reserved), which are divided into three categories: communication interrupt, input/output (I/O) interrupt and timebase interr···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China