Siemens SINAMICS GM150 Deep Maintenance

Published:2023-01-28 16:20:44

On-site maintenance

Check and clean pre-charge loop, rectifier unit, diode characteristics, inverter unit, GSV, AVT.

Rectifier module diagnostic test, and high voltage switchgear interface function test.

The IGBT POWERCARD of the GM150 is statically tested and cleaned to check the IGBT pairing condition.

Control cabinet inspection, BENDER insulation test, PT100, SITOP, etc.

CU320, TM31/15, AOP30, I/O terminal check.

Fiber optic connection and transmission characteristics, input/output cable connection and shielding conditions.

Tighten the ground copper bar, check the bolt fastening connection (torque), and insulation of the device.

On the control power, on the main power test, load running.

Record and analyze the output voltage, output current, speed (given value, actual value), DC bus waveform and other curves.

check

Check the operation of frequency converter on site.

Download and save frequency converter history, backup parameters, procedures.

Check the electrical installation and power cable layout.

Collect and monitor the output data.

Deep cleaning instructions

Use a brush and vacuum cleaner or dry compressed air to thoroughly clean the dust inside the cabinet. The scope of cleaning is the main internal components, other cleaning such as cabinet shell, cabinet body, external environment by Siemens technical staff to guide customers to complete.

Use cleaning agents to deeply clean the disassembled circuit boards, power components, internal connection busbars, and heat sinks.

Restore the test.

-

202302-15

202302-15What symptom does WEINVIEW touch screen motherboard malfunction have?

1. The motherboard cannot recognize/display peripheral devices.2. Peripherals will stop working for a few seconds or more.3. A slow startup may indicate that your motherboard is broken, although it co···

-

202410-16

202410-16Enhance Efficiency with ABB Variable Frequency Drive

The key to enhancing plant performance lies in the variable frequency operation of ABB. You can rely on us.Main advantages of ABB variable frequency operation1.️ Energy efficiency reduces energy cost···

-

202301-29

202301-29The role of Schneider instrument in air separation process

The surface of the instrument plays an important role in the air separation equipment and the process of gas purification. It is essential for the adjustment of the air separation process and the dete···

-

202212-29

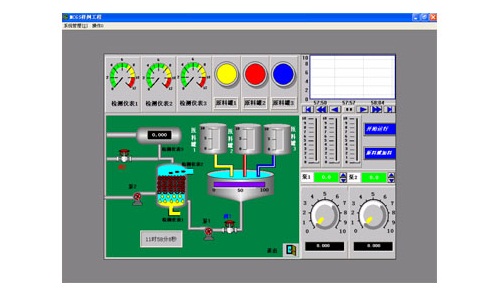

202212-29The composition of the configuration software of Kunlun MCGS embedded version

The user system generated by MCGS embedded version is composed of five parts: main control window, device window, user window, real-time database and operation strategy.1, the main control window: the···

-

202302-08

202302-08Reduce Schneider inverter interference measures

(1) Inductance and capacitance are added on the input side of Schneider inverter to form LC filtering network.(2) The power line of Schneider inverter is directly supplied from the transformer side.(3···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China