Siemens PLC controls Yamaha robots

Published:2023-01-28 16:00:06

This paper introduces the control strategy of Yamaha robot controlled by Siemens PLC, using the external IO port to set the command word, so that PLC can communicate with the robot, and instruct the robot to finish the corresponding action.

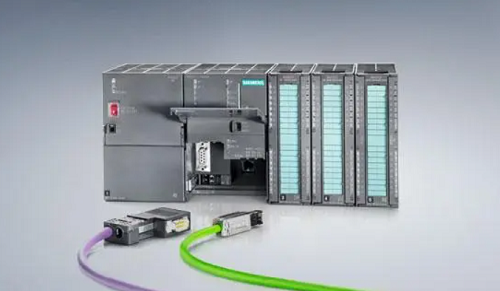

Siemens S7-300PLC is a widely used large and medium-sized PLC in our country now, research on it and peripheral robot control strategy in the field of device automation is of great significance. In this paper, based on the research and production of lithium battery line, the communication and control of Siemens S7300PLC and Yamaha robot are completed, and the research and development of the two key processes of steel bar and stamping in the process of lithium battery device is completed.

1. Overall hardware design

Siemens S7-300PLC and YAMAHA robot controller connection needs to connect the robot start signal, emergency stop signal, fault signal and reset signal, through the four groups of signals and PLC connection can reach the basic requirements of the control robot. PLC is connected with the robot. Generally, PLC is used as the sending instruction side and the robot is used as the receiving instruction side. In order to reach the purpose of PLC control robot walking to each point, the need to establish PLC and robot IO signal communication.

Combined with the technological research of steel laying and stamping procedures in the process of lithium battery device, it is obtained that the walking points of the robot will not exceed 16 points. According to the calculation of point points by 8421, the connecting points of the robot and PLC are 4 points. The PNP standard robot is selected to be connected with Siemens. The signal connection includes two parts: one part is the start, emergency stop, fault and reset signal; One part is the communication line between PLC and the robot at four points; There are eight sets of signals.

2. Overall software design

Software control strategy for robot inquiry, PLC command method to implement the whole control. Take the stacking robot as an example, the robot sends the signal 1001 inquiry after the return, the robot gets the signal according to the engineering requirements, the robot is instructed to go to the target orientation, the target orientation signal is (0001 -- 1011) a total of 9 points, get the point position robot moves in place, together in place after sending a signal to inform the robot in place, The robot controls the action of other peripherals (cylinders, motors, etc.), and tells the robot to return to position after the action is finished. After the robot returns to position, it continues to wait for the setting instruction. An action loop ends.

Through the communication and control between Siemens S7-300PLC and Yamaha robot, the research and development of steel bar and stamping of two key processes in the process of lithium battery device is completed. PLC and robot through the method of signal transmission end linkage used in the battery device field, has a good demonstration role; Can be used in other battery device sequence, other reference PLC and robot control method and control strategy, can end most of the PLC control robot to the point of work, has a good promotion effect.

-

202301-30

202301-30ABB frequency converter parameter setting method

1. GROUP99 Parameters: Apply macro to select standard macro, motor rating according to motor brand data, modify the set value.2. GROUP10 Parameter: Check whether parameter 1001 is 1. If no, set it to ···

-

202303-03

202303-03MCGS touch screen 485 communication precautions

1. Variables in the real-time runtime cannot simultaneously add channels and use functions to send data.2. In the parent device of the universal serial port, COM port indicates 232 or 485. In touch, C···

-

202302-03

202302-03Advantech mainboard circuit maintenance method

1. Visual inspection: by looking at the way, whether the machine board card is burned out, less, and other phenomena, to determine the damage2 touch: the human hand feels the machine board card and ot···

-

202212-30

202212-30ABB breaker failure and treatment

Judgment and handling of "reject" failureThe occurrence of "rejection" situation, basically in the closing operation and reclosing process. This kind of failure is very harmful. Fo···

-

202212-29

202212-29What symptom can WEINVIEW touch screen motherboard malfunction appear?

1. The motherboard cannot recognize/display peripheral devices.2. Peripherals will stop working for a few seconds or more.3. A slow startup may indicate that your motherboard is broken, although it co···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China