The role of Schneider instrument in air separation process

Published:2023-01-29 16:26:39

The surface of the instrument plays an important role in the air separation equipment and the process of gas purification. It is essential for the adjustment of the air separation process and the detection of product quality. Because there are different types of online analysis surfaces for monitoring different gas medium targets in each stage of the air separation process, the operation conditions in the distillation column can be understood through the output signals of the analysis surface, and the process can be controlled to produce 02, n2, ar and cryogenic liquids with qualified purity and output value requirements under the best working conditions. It also ensures that the high purity gas reaches the quality standard after purification.

Therefore, in the production process of gas and low-temperature liquid products of air separation equipment, it is necessary to accurately quantify and strictly control the composition of gas components in each stage of the process. At the same time, online chromatograph is used to automatically detect the content of hydrocarbons (full hydrocarbons and non-full hydrocarbons) in the main condenser and other parts of the air separation tower. It is an indispensable part in explosion - proof and safe production of air separation equipment.

Therefore, in the selection and analysis of instrument appearance, it is necessary to achieve and perform the following tasks:

1. Monitor the purity of process gas in the process to meet the gas purity requirements of each process segment;

2. Through the online analysis of the output data of the surface of the instrument, it can timely reflect and grasp the change of the working conditions of each process;

3. Can adjust the flow condition to operate in the best condition;

4. Ensure and manipulate the purity of gas products and low-temperature liquid products produced under safe conditions to meet the quality requirements and meet the ** standard;

5. The analysis of purified impurity components of high purity gas can reach the ** standard requirements.

-

202307-27

202307-27Siemens S7-200 SMART Common questions about serial communication

1. Does the S7-200 SMART support Modbus ASCII communication mode?STEP 7- The Micro/WIN SMART software does not provide the Modbus ASCII communication mode instruction library. If the S7-200 SMART CPU ···

-

202305-05

202305-05Delta inverter long-term idle points for attention

After the frequency converter is used for more than half a year, if the equipment is to be run again, the chance of damage may be greatly increased because of the placing environment, the service life···

-

202212-29

202212-29Schneider small circuit breaker and leakage switch difference

1. Definition of mini circuit breakerElectrical occupation for short MCB, suitable for communication 50/60Hz extra voltage 230/400V, extra current to 63A line overload and short circuit maintenance, a···

-

202302-03

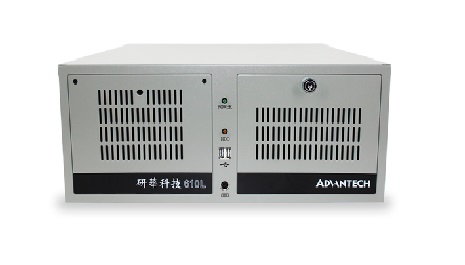

202302-03Reasons and solutions for the failure of Advantech Industrial computer

Advantech industrial computer can not open the machine may be industrial computer motherboard problemAdvantech industrial computer boot will self-check, to determine the condition of the machine, if t···

-

202301-17

202301-17Installation and commissioning steps of ABB robot accessories

General steps for ABB robot installation and commissioning:1. Lift the robot body and control cabinet into place2. Cable connection between ABB robot body and control cabinet3. ABB robot teaching devi···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China