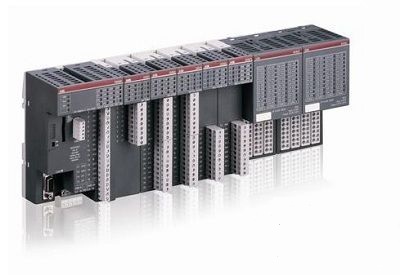

What are the PLC characteristics of ABB?

Published:2022-12-30 11:31:23

1, high reliability, strong anti-interference ability

High reliability, strong anti-interference ability is one of the most important characteristics of PLC. The average trouble-free time of PLC can reach hundreds of thousands of hours. The reason why it has such high reliability is that it adopts a series of anti-interference measures of hardware and software:

1) Hardware: I/O channel adopts photoelectric isolation, which effectively inhibits the influence of external interference sources on PLC; The high frequency interference is eliminated or suppressed by various forms of filtering for the power supply and the circuit. CPU and other important components are screened with good conductive and magnetic materials to reduce space electromagnetic interference; Some modules are equipped with interlock protection, self - diagnosis circuit, etc.

2) Software: PLC adopts scanning mode to reduce faults caused by interference of external environment; In PLC system program with fault detection and self-diagnosis program, can realize the system hardware circuit fault detection and judgment; When a fault is caused by external interference, it can immediately seal up the current important information and prohibit any unstable read and write operations. Once the external environment is normal, it can be restored to the state before the fault occurs and continue the original work.

2, simple programming, easy to use.

At present, most PLC programming language is ladder diagram language, it is a kind of production-oriented, user-oriented programming language. Ladder diagram and electrical control circuit diagram similar, image, intuitive, no need to master computer knowledge, easy to let the majority of engineering and technical personnel master. When the production process needs to be changed, the program can be changed on site, easy to use, flexible. At the same time, the operation and use of PLC programmer is also very simple. This is also one of the main reasons for the popularity and promotion of PLC.

Many PLC also for specific problems, designed a variety of special programming instructions and programming methods, further simplified programming.

3, perfect function, strong versatility

Modern PLC not only has logical operation, timing, counting, sequence control and other functions, but also has A/D and D/A conversion, numerical operation, data processing, PID control, communication networking and many other functions. At the same time, due to the serialization of PLC products, modularization, a complete variety of hardware devices for users to choose, can be composed to meet various requirements of the control system.

4, simple design and installation, convenient maintenance

As PLC replaces the hardware of the traditional electrical control system with software, the design, installation and wiring workload of the control cabinet is greatly reduced. PLC user program most can be simulated debugging in the laboratory, shorten the application design and debugging cycle. In maintenance, due to the PLC failure rate is very low, maintenance workload is very small; And PLC has a strong self-diagnosis function, if there is a fault, according to the PLC instructions or programmer prompt fault information, quickly identify the cause, maintenance is very convenient.

5, small size, light weight, low energy consumption

Due to the use of PLC integrated circuit, its compact structure, small size, low energy consumption, and thus become the ideal control equipment for mechatronics.

Programmable logic controller (PLC), which uses a class of programmable memory for its internal store programs, the execution of logical operations, sequence control, timing, counting and arithmetic operations and other user-oriented instructions, and through digital or analog input/output control of various types of machinery or production processes.

-

202306-30

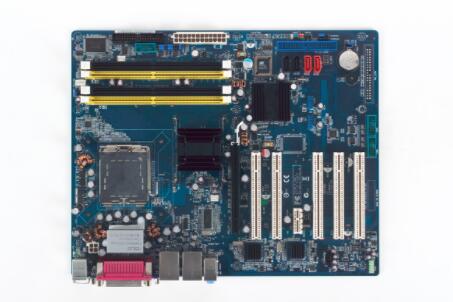

202306-30Advantech motherboard how to enter the U disk starter

If you can access the operating system before reinstalling the industrial computer system, you should back up important data and drivers to avoid the loss of important files due to system reinstallati···

-

202212-30

202212-30ABB breaker failure and treatment

Judgment and handling of "reject" failureThe occurrence of "rejection" situation, basically in the closing operation and reclosing process. This kind of failure is very harmful. Fo···

-

202212-29

202212-29Mitsubishi fetch instruction and output instruction

1.LD (fetch command) A normally open contact and the left bus connection command, each logic line with normally open contact start to use this command;2.LDI (take the reverse instruction) a normally c···

-

202302-13

202302-13Mitsubishi PLC communication detection steps

When you are ready to communicate through the AJ71QE71, perform the ping procedure in MS-DOS mode before starting the communication with Mitsubishi PLC's GPPW to see if the connection is correct. ···

-

202302-20

202302-20This section describes how to set the bios after the Advantech 610l is powered on

1. Press Del to enter BIOS Settings. The following main menu is displayed.2. Select the IntegratedPeripherals TAB and press Enter to enter the menu below.3. Select SupperlODevice and press Enter to ac···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China