Delta PLC maintenance knowledge introduction

Published:2023-01-12 16:46:44

1. Delta PLC power-on running light is not on, ERROR flickers, the possible cause is: no program

2. Delta PLC can not communicate with the computer, which may be: RS23 is bad

3. If the power indicator of Delta PLC is off, the power supply is bad

4 Delta PLC needs to send pulse should select the output transistor type PLC

5. Delta PLC output indicator light on, but no output: output point is broken

6. Delta PLC input cable is normal, the input terminal is closed, but the input indicator is off: the input point is bad

8. Power on Delta PLC BAT.LOW on: The battery is low

10. Delta PLC power-on burning power supply insurance: short circuit of the power board

11. All indicators of Delta PLC are normal, and all output points cannot operate: output expansion IC is broken

12. All the indicators of Delta PLC are normal, and the input contacts do not respond: RS232 is broken

13 Delta PLC simulation quantity has what control mode: temperature, liquid level

14 Delta PLC external communication port: RS232, RS485

15. Delta PLC voltage drops to the lower limit of voltage how to do: timely replacement

16. Delta PLC running light is not on, program input is normal, running switch has been closed, what is the reason: CPU bad

17. Delta PLC has 24V output but the power indicator is off: +5V power circuit is abnormal

18. Which Delta PLC can not be extended: DVP-EC3

19. Is Delta weighing module extended on the left side or the right side? Left side

20. The output pulse of DVP20PM00M can reach: 500HZ

-

202212-30

202212-30Gongboshi killing robot four advanced functions

The robot has four advanced functions: mask detection, explanation and reception, autonomous navigation and accurate obstacle avoidance, and cloud data management.The robot has the same voice interact···

-

202302-13

202302-13Mitsubishi PLC communication detection steps

When you are ready to communicate through the AJ71QE71, perform the ping procedure in MS-DOS mode before starting the communication with Mitsubishi PLC's GPPW to see if the connection is correct. ···

-

202212-29

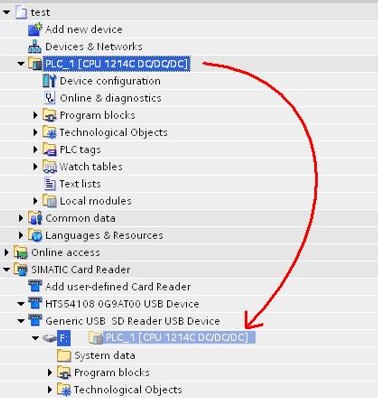

202212-29Siemens loads items into a memory card in transfer mode

Loads items to a memory card in transfer modeStep 1: Set the memory card to "transfer card" mode according to the above method. You are advised to clear all files from the memory card before···

-

202306-21

202306-21Delta servo motor regular diagnosis and repair method

First, the motor temperature is too high or the smoke motor common failureReasons :1. The load is too large; 2. Two-phase operation; 3. Air duct obstruction; 4. The working temperature is too high; 5.···

-

202307-07

202307-07The alarm code cause and diagnosis method of the cabinet air conditioner of Rittal

Alarm code: A01System message: Open the cabinet doorAir conditioning cause: The opening and closing position is incorrectDiagnostic method: Check the transition position of the door and, if necessary,···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China