Schneider instrument maintenance precautions

Published:2022-12-29 15:51:58

1. When installing and adjusting the appearance, the original status should be recorded in order to recover.

2, repair the appearance of fine instruments, such as accidentally small parts flying, should be the first to determine the location of the flying, do not look for the east, the west over, can adopt magnet scanning and visual field scanning method to find.

3, inspection without consciously knock knock, in order to prevent the expansion of shortcomings, the more repair worse.

4, do not plug all kinds of control board and plug.

5, inspection of the external circuit, assuming that the device components of the contact and circuit board coated with insulation varnish, measuring the parameters of each point can be used in the common hand needle welding on the pen of the multimeter, in order to puncture the paint layer directly measured each point, without a large area of peeling paint layer.

6. When inspecting the appearance defects in a humid environment, it is necessary to use a multimeter to measure the hysteresis of each point of the printed circuit, because the important shortcoming in this case is copper foil corrosion.

7. When detecting the filter capacitor in the power supply, the positive and negative electrodes of the electrolytic capacitor should be short circuited first, and the short circuit does not need to use the marker line to replace the wire to discharge the capacitor, because this will burn the core wire. Can take a 220V, 60-100W lamp with a cap lead, connected to the capacitor at both ends, in the discharge of the bulb will flash.

8. When using logic pen and oscilloscope to detect signals, attention should be paid not to make the probe contact the two measuring pins together, because the nature of this situation is to constitute a short circuit in the case of power.

-

202212-30

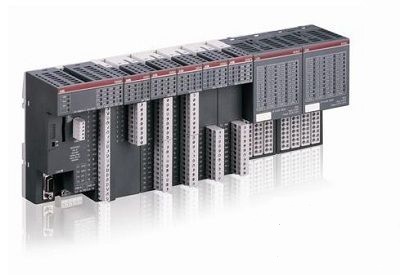

202212-30What are the PLC characteristics of ABB?

1, high reliability, strong anti-interference abilityHigh reliability, strong anti-interference ability is one of the most important characteristics of PLC. The average trouble-free time of PLC can re···

-

202303-02

202303-02Mitsubishi servo motors one-button adjustment function

When different servo motors are installed on the machine for the first time, they will occasionally show a poor match with the machinery during operation, which will lead to vibration, noise and other···

-

202302-24

202302-24WEINVIEW touch screen common faults and maintenance

(1) The startup indicator is normal, but the display shows no signal input (black screen);(2) Press the on key, the host does not have any response (the indicator light is not bright, the host startup···

-

202303-08

202303-08How to choose Schneider Circuit Breaker?

First calculate the current value of each branchPure resistive load, such as light bulbs, electric heaters, etc., with the indicated power directly divided by the voltage, the formula I= power /220v; ···

-

202302-27

202302-27How does Delta inverter adjust the frequency?

Delta frequency converter, frequency adjustment is mainly operated in the control panel, process:1. Press the Menu button to enter the parameter programming menu.2, P0.01=1, input this parameter to co···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China