Designed for industrial applications by Omron Automation Pvt ltd, the 3 phase frequency converter is suitable for 45kW motors with a rated voltage of 200-240VAC. It is a 400hz frequency converter, with powerful energy-saving capabilities and excellent control performance, and is widely used in various industrial scenarios to effectively improve production efficiency and equipment stability.

Product Specifications

Rated Power: 45kW

Rated Voltage: Three-phase 200-240VAC

Control Method: Supports sensorless vector control and V/F control

Frequency Range: 0-400Hz

Protection Functions: Overload, overheat, overvoltage, undervoltage, and other protections

Communication Interface: Built-in RS485 interface, supporting Modbus-RTU protocol

Environmental Adaptability: Operates in ambient temperatures ranging from -10°C to +50°C

Product Features

High-Precision Control: The sensorless vector control mode achieves high-precision speed and torque control.

Energy-Efficient: Optimized control algorithms and energy-saving modes effectively reduce energy consumption.

User-Friendly: Equipped with a digital operator that supports multiple languages, making parameter settings intuitive.

High Compatibility: Supports various types of motors, adapting to different application scenarios.

Applications

Industrial Automation: Used for driving machines such as machine tools, conveyors, fans, and pumps.

HVAC: Regulates the speed of fans and pumps to achieve energy savings.

Mechanical Processing: Precisely controls motor speed to enhance processing accuracy.

Usage Instructions

Installation and Wiring: Install in a well-ventilated, dust-free, and non-corrosive gas environment. Follow the wiring diagram in the product manual to ensure correct connections of power, signal, and motor wires.

Parameter Settings: Set basic parameters according to application needs, such as motor parameters, control methods, and frequency range. For complex applications, configure advanced functions like PID control and multi-speed control.

Maintenance and Inspection: Regularly check the appearance, heat sink, fans, and other components of the inverter. Periodically verify parameter settings to ensure they match the application requirements.

Precautions

Environmental Conditions: Avoid using in high-temperature, high-humidity, or strong electromagnetic interference environments.

Power Requirements: Ensure stable power voltage to prevent damage to the inverter from voltage fluctuations.

Safety Operations: Avoid contact with live parts during equipment operation.

Frequently Asked Questions (FAQ)

How to perform motor auto-tuning on the OMRON 3G3RX2-A2370?

Importance of Auto-Tuning: Auto-tuning is a crucial step to ensure compatibility between the inverter and the motor, improving control accuracy and system stability. First, set the motor's nameplate parameters, including power, rated voltage, and rated current.

Precautions During Auto-Tuning: During auto-tuning, the inverter injects current into the motor. Ensure the motor is correctly connected to the inverter and that the inverter is in a ready state. Also, ensure the motor is stationary to avoid damage during auto-tuning.

Effect After Auto-Tuning: After completion, the inverter automatically adjusts control parameters based on the actual motor parameters to achieve optimal performance.

How to configure the communication interface of this 400hz frequency converter?

Communication Interface Type: The OMRON 3G3RX2-A2370 supports RS485 communication with the built-in Modbus-RTU protocol.

Communication Line Connection: Ensure correct connection of the communication lines. Use shielded cables and ensure the shielding is properly grounded to reduce electromagnetic interference.

Communication Parameter Settings: Set the communication address, baud rate, data bits, stop bits, etc., according to the protocol requirements. Ensure consistency with the upper-level machine's communication parameters for reliable connections.

How to avoid electromagnetic interference with this 3 phase frequency converter series product?

Built-in Filter: This product of Omron Automation Pvt ltd has an integrated EMC filter that meets relevant electromagnetic compatibility standards to effectively suppress interference.

Wiring Precautions: Avoid placing signal and power cables close together during wiring. Use shielded cables for signal lines and ensure proper grounding of the shielding.

Grounding Measures: Proper grounding is essential to reduce electromagnetic interference. Ensure the equipment is well-grounded and complies with national and local electrical safety regulations.

How to select the power range of this frequency inverter?

Select Based on Load Requirements: Determine the inverter's power range based on the actual load of the motor. If the load is light, choose an inverter matching the motor's rated power. For heavy loads or high starting torque, select a higher-power inverter.

Safety Factor: Consider the system's safety factor when selecting the power range. It is generally recommended to choose an inverter slightly larger than the motor's rated power to handle load fluctuations and emergencies.

Overload Capability: This 400hz frequency converter has some overload capacity for short-term operation above rated power. However, long-term overloading can affect the inverter's lifespan and performance, so avoid prolonged overloading when selecting the power range.

What is the cooling method of the OMRON 3G3RX2-A2370?

Cooling Method: This 3 phase frequency converter series product uses forced air cooling with an integrated cooling fan.

Installation Requirements: Ensure sufficient space around the frequency inverter for air circulation during installation. Avoid placing it in enclosed or poorly ventilated environments to maintain effective cooling.

Maintenance: Regularly clean the fan and heat sink to prevent overheating due to poor cooling. Check the fan's operation to ensure it is working properly.

What protection functions does the OMRON 3G3RX2-A2370 have?

Overload Protection: When the motor load exceeds the rated value, the inverter automatically reduces frequency or stops to protect the motor and inverter.

Overheat Protection: This 400hz frequency converter has an internal temperature sensor that automatically shuts down when the temperature exceeds the set value to prevent damage from overheating.

Overvoltage and Undervoltage Protection: The inverter automatically shuts down when the power voltage is too high or too low to protect the equipment. It also features short-circuit and phase-loss protection to ensure safe system operation.

How to perform regular maintenance on this 3 phase frequency converter series product

Appearance Inspection: Regularly check the inverter's appearance for damage or abnormalities, such as cracks in the housing or loose screws.

Cooling System Maintenance: Clean the fan and heat sink to ensure the cooling system works properly. Check the fan's operation and replace it if there are any issues.

Electrical Connection Check: Ensure the power and signal connections are secure and make contact. Check the motor's operating condition to identify and address any abnormalities promptly.

What should be considered when installing this converter of Omron Automation Pvt ltd?

Installation Location: Choose an environment with good ventilation, free from dust and corrosive gases. Avoid installing the inverter in high-temperature, high-humidity, or strong electromagnetic interference areas.

Installation Method: Ensure vertical installation for effective cooling. Use appropriate fixing methods to prevent vibration damage to the equipment.

Power Connection: Ensure the power cable meets the required specifications and check the phase sequence. Ensure proper grounding of the equipment.

How to select the control mode for this frequency inverter?

Select Based on Application Needs: For applications requiring high-precision speed control, choose sensorless vector control mode. For general constant-speed control, choose V/F control mode.

Control Mode Characteristics: Sensorless vector control mode provides high-precision speed and torque control, suitable for applications with high control accuracy requirements. V/F control mode is simple and easy to use for general constant-speed control.

Parameter Settings: After selecting the control mode, configure the parameters according to the specific application needs to achieve the best control effect.

How to set the frequency setting channel for the OMRON 3G3RX2-A2370?

Frequency Setting Methods: Frequency can be set through the inverter panel, external analog signals, or digital signals. Users can select the appropriate frequency setting method based on their application needs.

Signal Source Requirements: Ensure the stability and accuracy of the signal source when setting the frequency setting channel. For example, when using an external analog signal for frequency setting, ensure the signal's stability and interference resistance.

Parameter Configuration: Configure the parameters according to the selected frequency setting method. For example, for external analog signal settings, set the input range of the signal and the corresponding frequency range.

FAQ

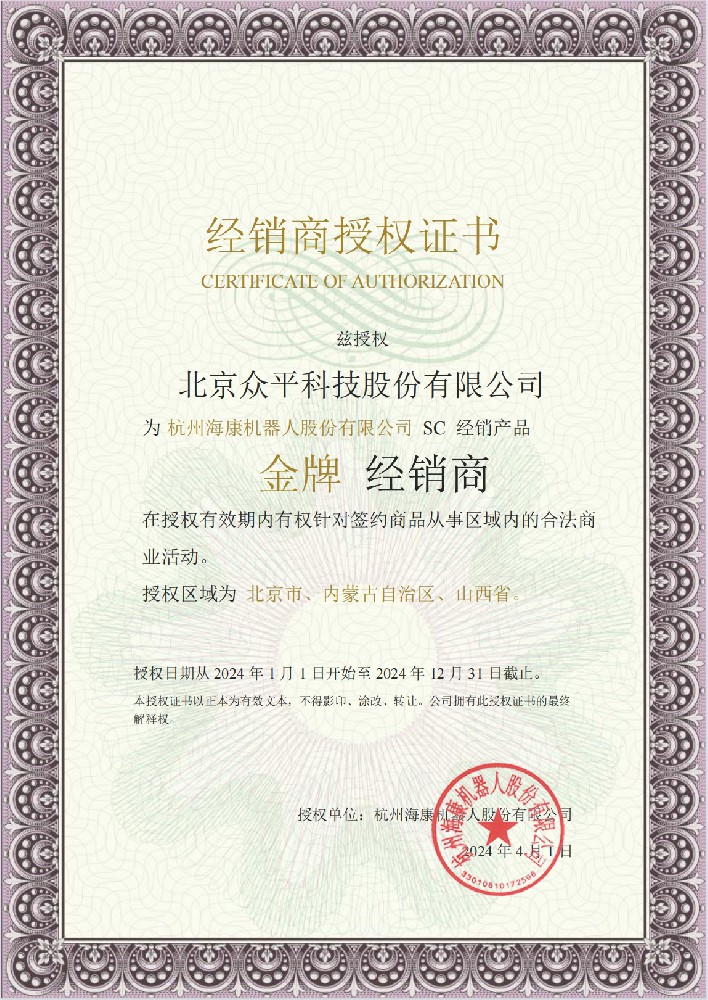

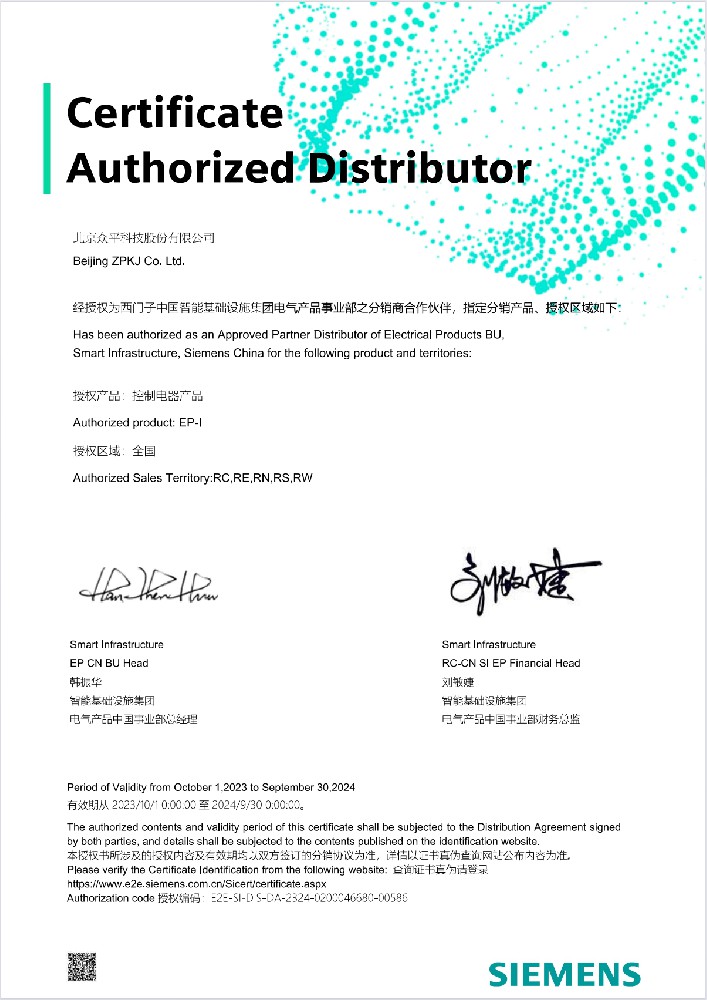

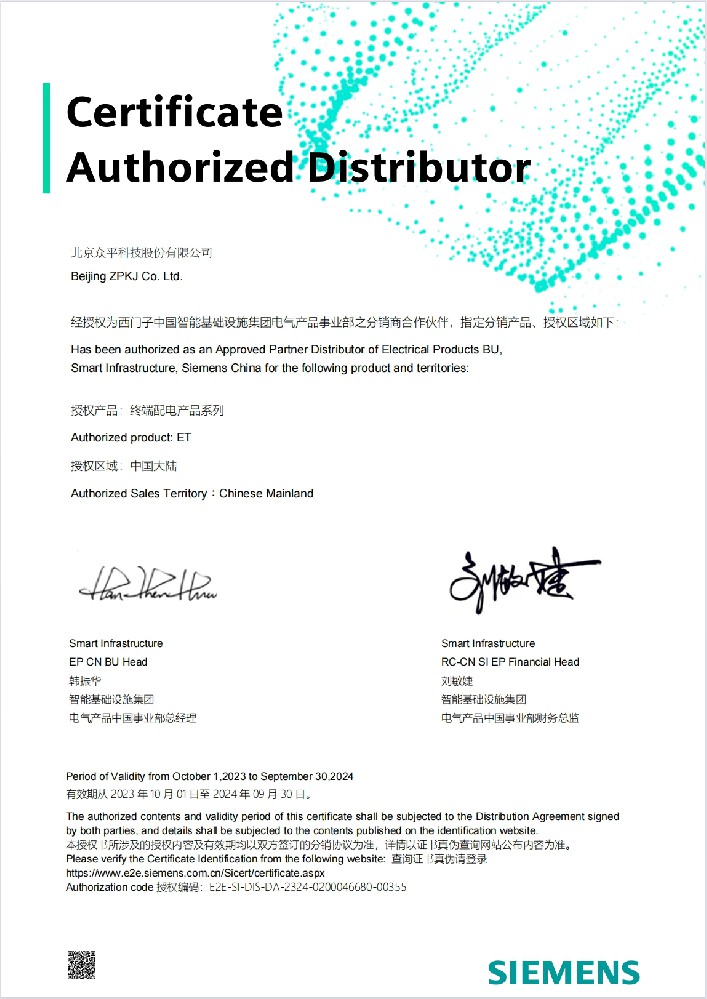

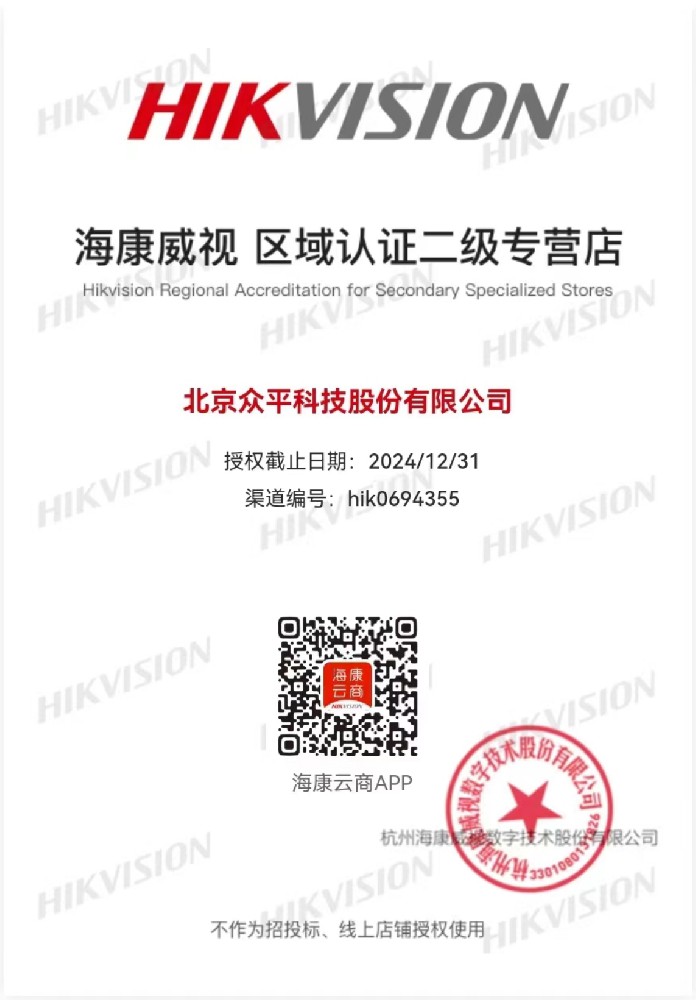

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China