Product Introduction

OMRON, a leading brand in the industrial automation industry, has meticulously crafted the 3G3RX2-A2220 inverter as a power control device. With its exceptional performance and reliable quality, it provides solutions for a wide range of industrial applications.

Product Specifications

Rated Voltage: Three-phase AC 200V

Maximum Applicable Motor Capacity: 30kW

Rated Output Current: The rated output current for the 3G3RX2-A2220 is 50A.

Protection Structure: IP20

Product Features

High-Performance Control: Utilizes advanced control algorithms to achieve high-precision speed and torque control. It excels in low-frequency startup, providing strong power even when the motor is nearly stationary, easily overcoming load inertia for smooth and rapid startup. This is particularly suitable for heavy-load startup scenarios such as large conveyor belts and initial compressor startups.

Rich Functionality: Equipped with multiple protection mechanisms to safeguard the equipment comprehensively.

Overcurrent Protection: Monitors current anomalies in real-time, quickly cutting off power to prevent circuit burnout if the threshold is exceeded.

Overvoltage Suppression: Addresses grid voltage fluctuations and instantaneous surges, stabilizing output voltage.

Emergency Stop Function: Responds swiftly to emergencies, immediately braking the motor to ensure the safety of personnel and equipment.

Micro-Surge Voltage Suppression: Further purifies power quality, reducing the risk of voltage spikes damaging the equipment.

Significant Energy Saving and Efficiency Improvement: By optimizing the frequency control algorithm, it dynamically adjusts the motor supply frequency and voltage according to actual load demands, avoiding energy waste during light or no-load conditions, achieving significant energy savings.

Application Scenarios

Industrial Manufacturing Production Lines: In automotive manufacturing, mechanical processing, and electronic assembly production lines, precise control of motor speeds at various stages is crucial. The 3G3RX2-A2220 inverter can flexibly adjust the speed of conveyor belts, robotic arms, and tool drive motors according to process requirements, ensuring precise production rhythms and improving product quality and production efficiency.

HVAC Systems: Used in central air conditioning, ventilators, and chilled water pumps, it dynamically adjusts motor operation frequency based on indoor and outdoor temperature and humidity changes, achieving precise matching of cooling and air supply volumes. This not only ensures a comfortable environment but also significantly reduces energy consumption, creating an energy-efficient and comfortable space for commercial buildings and factory workshops.

Water Supply and Drainage Treatment: In urban water supply and sewage treatment plants, it drives pump motors, intelligently controlling pump speed based on real-time water pressure, water level, and flow demands. This ensures stable water supply and smooth drainage, avoids water waste and excessive equipment wear, and enhances the reliability of municipal facilities.

Usage Instructions

Grounding Protection

Ensure that the equipment is properly grounded in accordance with national and local electrical safety standards.

Installation Environment

Choose a dry, well-ventilated location away from heat sources and strong electromagnetic interference. Ensure the installation surface is flat and sturdy, with sufficient load-bearing capacity.

Inspection of Accessories

Check that all accompanying cables, terminal blocks, and other accessories are complete.

Wiring Operations

Strictly follow the electrical wiring diagram in the product manual. Distinguish between different wiring ports such as power input, motor output, and control signals. Ensure that all connections are secure and free from looseness. After completing the wiring, carefully inspect to prevent short circuits, open circuits, and other errors. Pay special attention to grounding protection to ensure the safety of the equipment and personnel.

Parameter Settings

Before powering on, familiarize yourself with the functions of the inverter's operation panel. After powering on, enter the parameter setting interface and set basic parameters such as rated voltage, current, frequency, and control mode according to the motor's nameplate parameters and application requirements. Also, set operational parameters such as acceleration time, deceleration time, and torque compensation. Save the settings and perform a trial run, adjusting parameters as necessary based on actual operating effects.

Maintenance and Inspection

Daily Cleaning

Regularly clean the surface of the inverter to remove dust and debris. This prevents dust accumulation from affecting heat dissipation and prevents debris from entering ventilation ports and terminal blocks, which could cause faults. It is recommended to perform a simple cleaning once a month.

Heat Dissipation Check

Monitor the operation of the cooling fans, checking for any damage or deformation of the blades, and ensuring smooth and quiet operation. Regularly clean the fan filters to ensure unobstructed airflow. If a fan fault is detected, replace it promptly.

Electrical Performance Testing

Conduct electrical performance tests every quarter or half-year. Use professional instruments to measure input and output voltage and current, check grounding resistance, and inspect the connections of all terminal blocks. Address any abnormalities promptly.

Precautions

Avoid Overloading: Ensure that the motor and load are selected according to the inverter's rated capacity. Do not exceed its rated load capacity. Long-term overloading will accelerate equipment aging and damage, and may even cause safety accidents.

Cope with Grid Fluctuations: If the local grid quality is poor with frequent voltage fluctuations, consider adding a voltage stabilizer or filter to ensure the stability of the input power to the inverter, preventing equipment damage due to grid anomalies.

Operational Safety Protection: When debugging or maintaining the inverter, ensure the power is disconnected and the capacitors are fully discharged before proceeding. Operators should wear insulating gloves and use insulated tools to prevent electric shock. Non-professionals are strictly prohibited from disassembling or repairing the equipment.

Common Questions FAQ

What size motor can this inverter drive?

What special scenarios require the maximum output frequency of 590Hz?

How does the starting torque performance stand out in practical applications?

It has a significant advantage in low-frequency startup, achieving a starting torque of over 200% at 0.3Hz. When starting large conveyor belts and compressors, it can overcome resistance for a quick and smooth startup.

How much does closed-loop vector control technology improve device operation precision?

Coupled with high-precision sensor feedback, it can monitor the motor status in real-time with high precision. In CNC machines, it can precisely control tool cutting, and in automated production lines, it ensures coordinated operation of motors at various workstations, thereby reducing the production of defective products.

How is the energy-saving effect of this inverter specifically reflected?

In variable torque loads such as fans and pumps, it dynamically adjusts frequency and voltage according to the load, achieving energy savings of 30% - 60%. For example, central air conditioning can adjust the speed of ventilators based on room temperature to achieve energy savings.

What are the special requirements for the installation environment?

Choose a dry, well-ventilated location away from heat sources and strong electromagnetic interference for installation. Damp, poorly ventilated, or environments near heat sources or with strong electromagnetic interference can easily cause equipment failures.

Is the wiring operation complex? Can non-professionals complete it?

Wiring operations must be strictly carried out according to the manual, involving multiple ports. Cables must be securely connected and properly grounded. Due to electrical safety concerns, it is recommended that non-professionals do not perform the operation and that professional engineers handle it.

What does daily maintenance involve, and how often should it be done?

Clean the surface of the equipment with a dry soft tool at least once a month to prevent heat dissipation obstruction. Pay attention to the cooling fans and regularly clean the filters. Conduct electrical performance tests such as voltage, current, and grounding resistance every quarter or half-year.

Can it operate normally during voltage fluctuations?

What are its advantages compared to other similar brand inverters?

OMRON has a good reputation and high-quality after-sales service. In terms of performance, it offers high starting torque, precise closed-loop control, comprehensive protection functions, and excellent energy-saving effects. It has a wide range of applications, covering multiple fields, and can meet a variety of user needs in one go.

The above content is for reference only. For specific information, please refer to the product manuals and materials provided by OMRON.

FAQ

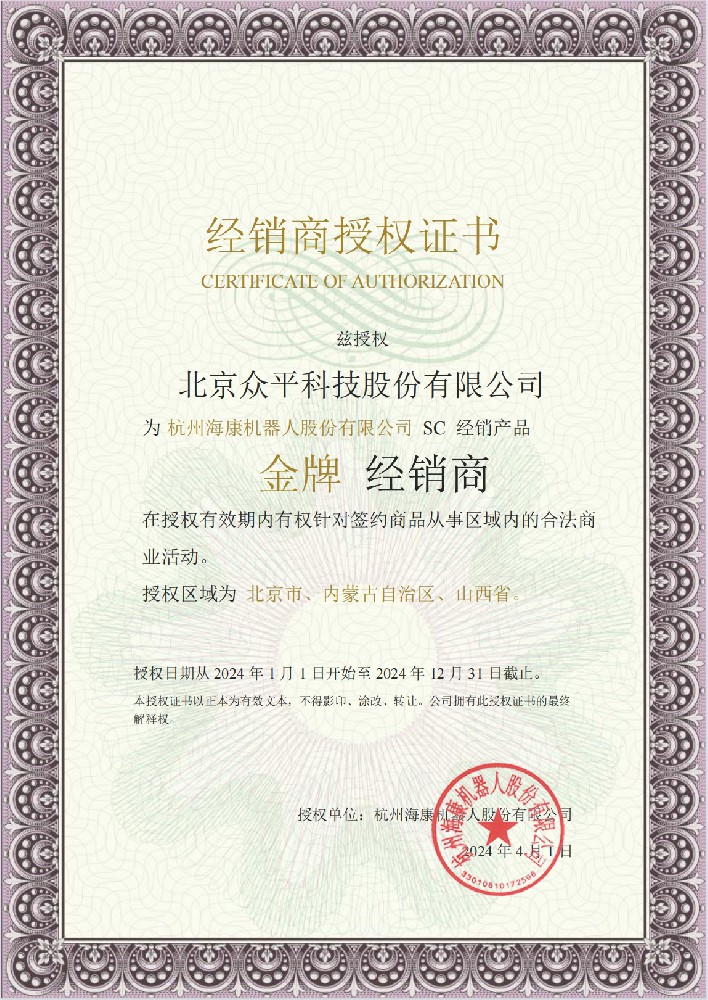

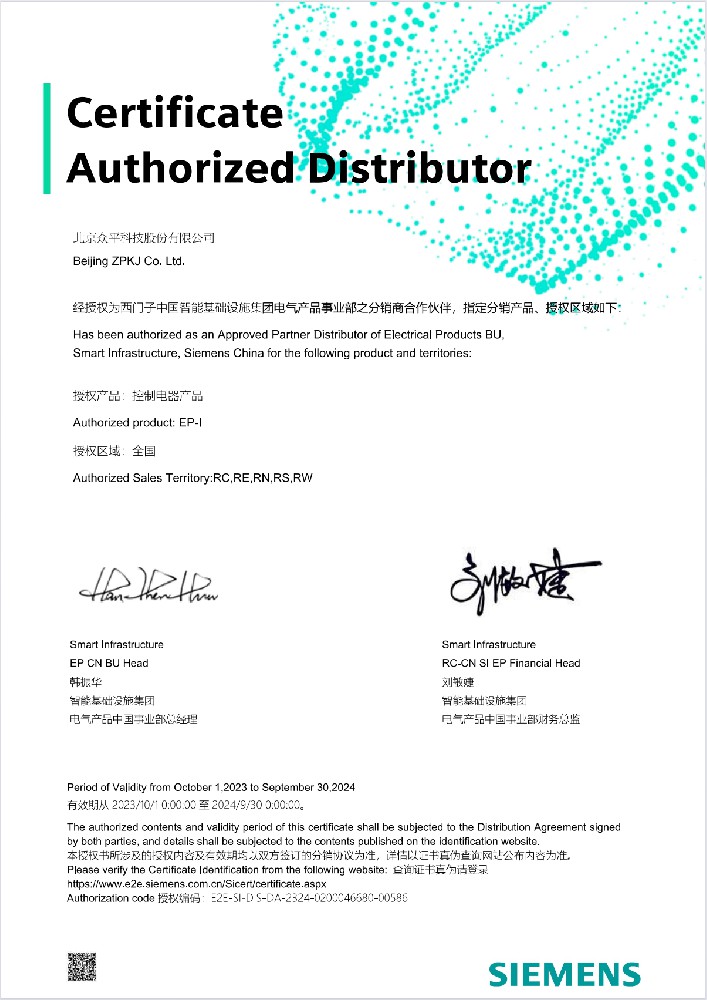

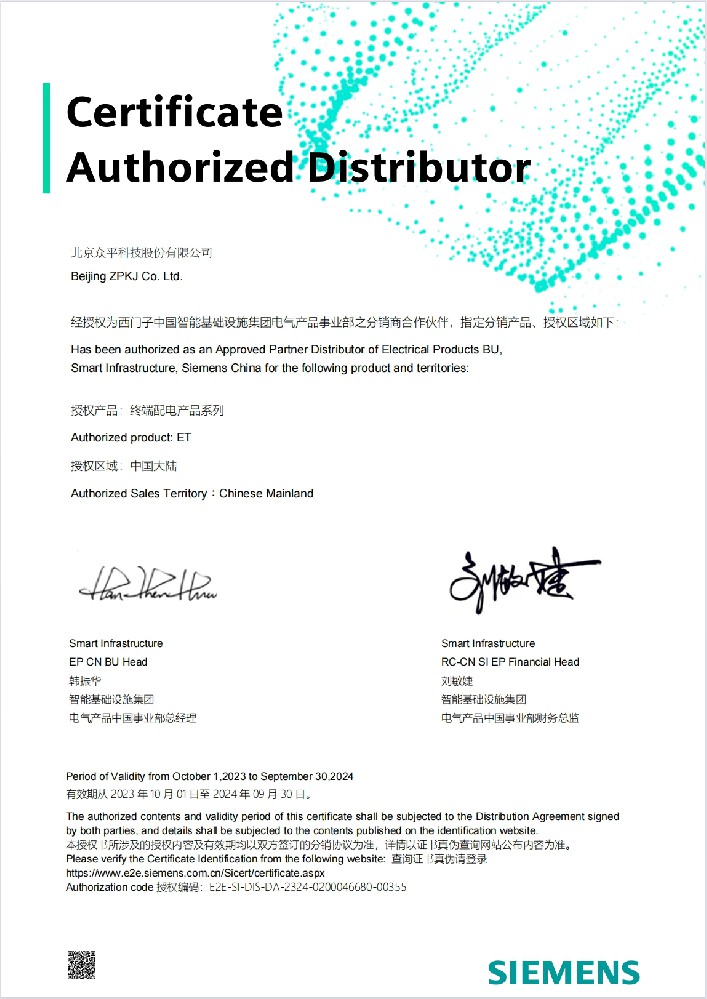

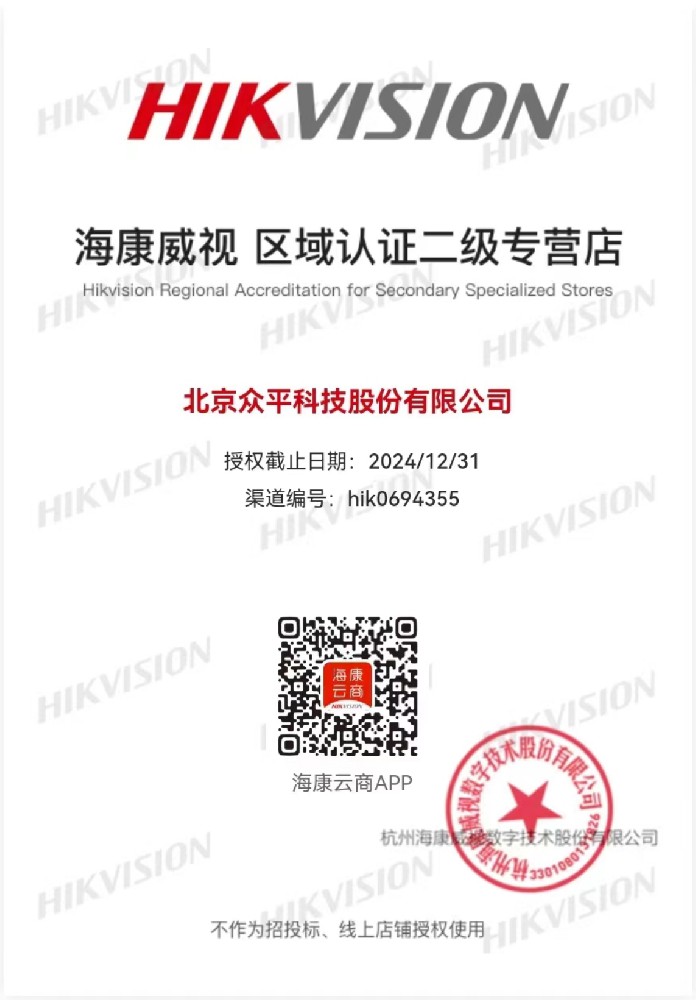

1.Who are We?

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China