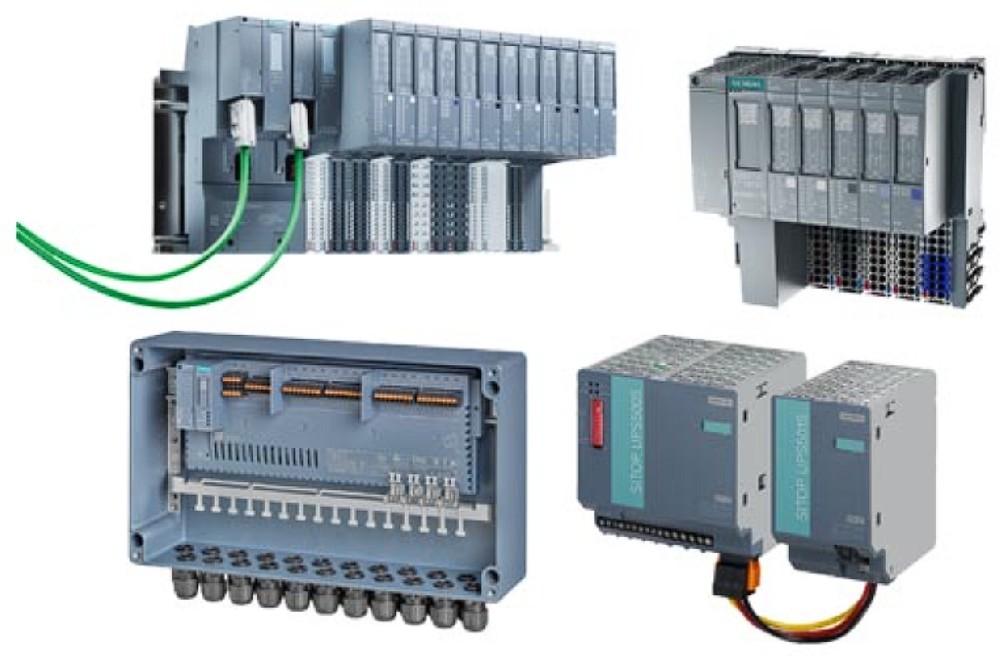

Input and Output Modules: Everything You Need to Know

Published:2024-10-21 17:01:03

I/O modules(input/output modules)manage the communication between the CPU and the network,including data transfer,power load management,and machine function control.It enables system integrators to connect different devices and better manage industrial networks,especially for dealing with older machines,equipment,and systems that cannot communicate naturally using the required industrial protocols.

1.I/O Module Overview

Main functions

Error detection:It has error detection capabilities and can identify and report errors to the CPU through methods such as parity bits.

Processor communication

Command decoding:Receives and interprets commands sent by the processor.

Data exchange:Facilitates data exchange between peripherals,processors,and main memory.

Status reporting:Reports processor status updates to peripherals.

Address decoding:Organizes connected peripherals by managing unique addresses.

Data buffering:Controls the speed of data transfer from the processor to the peripherals and compensates for peripheral delays.

Device communication:Enables communication between connected peripherals.

Control and timing:Supervises data transactions between internal systems and peripherals.

2.Types of I/O communication methods

Programmed I/O:Data transfer from I/O devices to memory requires the CPU to start a program,and the CPU will keep looping until the I/O device is ready to transfer data.

Interrupt-driven I/O:The CPU issues a read command to the I/O device,and when the device is ready to transfer data,it sends an interrupt signal to the processor,and then the CPU checks the device status and writes the information to the memory when the device is ready.

Direct memory access(DMA):I/O devices can send and receive data directly from memory,completely bypassing the CPU and increasing the speed of memory operations.

3.Categories of input and output module

Input categories:sensory input,digital input,analog input.

Output categories:control output,direct digital output,modulated digital output,analog output,data transmission(parallel and serial).

4.The role of I/O modules in PLCs

I/O modules are integrated into PLCs or added to PLCs to enhance their functionality,connectivity,and process control.They manage incoming communications to the PLC and execute commands sent by the processor,making it possible to detect errors,exchange data,buffer information,and supervise data transactions between internal systems and peripherals.

5.The difference between analog I/O and digital I/O

Analog signals:are continuous and represent a continuous range of valuesthat change over time,such as sound waves,current or voltage measurements.

Digital signals:operate in binary form,usually represented as"on"or"off","1"or"0",are discrete and not continuous like analog signals.With the popularity of digital technology,digital I/O is becoming the standard in data collection,but analog signals are still in use and can also be converted to digital signals.

-

202212-29

202212-29What symptom can WEINVIEW touch screen motherboard malfunction appear?

1. The motherboard cannot recognize/display peripheral devices.2. Peripherals will stop working for a few seconds or more.3. A slow startup may indicate that your motherboard is broken, although it co···

-

202303-24

202303-24How does the WEINVIEW touch screen connect with the Omron NJ controller?

First, Omron NJ controller programming1. Create the structure data type required by the project. For example, the Boolean switch quantity used in this example is combined to establish a structure data···

-

202307-07

202307-07The alarm code cause and diagnosis method of the cabinet air conditioner of Rittal

Alarm code: A01System message: Open the cabinet doorAir conditioning cause: The opening and closing position is incorrectDiagnostic method: Check the transition position of the door and, if necessary,···

-

202302-17

202302-17New features of Siemens SIMATIC S7-1200 PLC V2.0

In addition to the existing product features, SIMATIC S7-1200 V2.0 adds the following mechanisms and features:Integrated PROFINET-IO controller interface with integrated PROFINET interfaceProfibus DP ···

-

![[Gongboshi case] electric control cabinet box welding - Doctor of engineering independent brand to help customers intelligent upgrade production line](/static/upload/image/20221230/1672385439299376.png) 202212-30

202212-30[Gongboshi case] electric control cabinet box welding - Doctor of engineering independent brand to help customers intelligent upgrade production line

Welding of electric control cabinet cabinetIn this case, the welding robot is combined with the Doctor of engineering robot positioner and gun cleaning station to realize the automatic welding of the ···

+8618621383628

+8618621383628 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China