EM3A inertia 1500 r/min 1.3KW servo motor EM3G-13DTA244

Power: 1.3KW

Connector: Aviation socket

Flange: 130mm

Axle diameter: Φ22

Drive: ED3L-15A

Plug in power: three-phase AC

380V~440V

Power cable: EC3P-B9314-□□

Encoder cable:

EC3S-A1924-□□ (Battery included)

EC3S-I1924-□□ (No battery)

Servo motor:

servo motor (servo motor) refers to the engine that controls the operation of mechanical components in the servo system, which is a supplementary motor indirect transmission device.

The servo motor can control the speed, the position accuracy is very accurate, and the voltage signal can be converted into torque and speed to drive the control object. Servo motor rotor speed is controlled by the input signal, and can react quickly, in the automatic control system, used as an executive component, and has a small electromechanical time constant, high linearity characteristics, the received electrical signal can be converted into the angular displacement or angular speed output on the motor shaft. Divided into DC and AC servomotor two categories, its main feature is that when the signal voltage is zero, there is no rotation phenomenon, and the speed decreases with the increase of torque.

The Sayton motor control family

Industry solutions: Packaging, 3C, lithium, logistics, robot, photovoltaic, semiconductor

Information layer: production line manager, edge gateway, operation and maintenance wizard

Control layer: TRIO Control System, HMI

Drive layer: DX3 driver, DX4 driver, DX5 driver, DX3L driver, DE3S driver, EV1S inverter

Execution/Sensing layer: EM3A,EM3J,EM3G, linear motor, encoder, camera, lens, photoelectric sensor, inductance sensor

Servo motor working principle:

1, servo system (servo mechanism) is an automatic control system that enables the object's position, orientation, state and other output controlled quantity to follow any change of the input target (or given value). The servo mainly depends on the pulse to position, basically can be understood in this way, the servo motor receives a pulse, it will rotate the corresponding Angle of a pulse, so as to achieve displacement, because the servo motor itself has the function of pulse, so each rotation Angle of the servo motor, will emit the corresponding number of pulses, so that the pulse accepted by the servo motor echoes. Or closed loop, so that the system will know how many pulses are sent to the servo motor, and how many pulses are received back, so that the rotation of the motor can be greatly controlled, so as to achieve positioning, which can reach 0.001mm. Dc servo motors are divided into brushed and brushless motors. Brush motor has low cost, simple structure, large starting torque, wide speed regulation range, easy control, and needs maintenance, but the maintenance is not convenient (change the carbon brush), electromagnetic interference, and the environment is required. Therefore, it can be used in cost-sensitive general industrial and civil applications.

Brushless motor small size, light weight, large output, fast response, high speed, small inertia, smooth rotation, torque stability. The control is complex, easy to achieve intelligence, its electronic commutation mode is flexible, can be square wave commutation or sine wave commutation. The motor is maintenance-free, high efficiency, low operating temperature, small electromagnetic radiation, long life, and can be used in a variety of environments.

2, AC servo motor is also a brushless motor, divided into synchronous and asynchronous motors, motion control is generally used synchronous motor, its power range is large, can achieve a lot of power. Large inertia, the highest rotation speed is low, and it decreases rapidly with the increase of power. Therefore, it is suitable for low speed and smooth operation applications.

3, the rotor inside the servo motor is a permanent magnet, the driver control of U/V/W three-phase electric electromagnetic field, the rotor rotates under the action of this magnetic field, while the motor comes with the encoder feedback signal to the driver, the driver according to the feedback value and the target value to compare, adjust the rotor rotation Angle. The accuracy of the servo motor is determined by the accuracy of the encoder (number of lines).

The difference between AC servo motor and brushless DC servo motor in function: AC servo is better, because it is sine wave control and torque ripple is small. Dc servo is trapezoidal wave. But DC servo is simpler and cheaper.

Eston Automation (Shenzhen Stock Exchange listed company, stock code 002747) was founded in 1993, the company from the day of establishment, adhere to integrity, focus, total growth as the cornerstone of the company's development, adhere to the development of independent research and development of core technology, for the company to go global, To become an international enterprise respected by the peers to lay a solid foundation of integrity.

After nearly 30 years of continuous efforts by all employees of the company, thanks to the company's focus on the layout of the complete ecological chain of automation, long-term research and development investment of about 10% of annual revenue, and the strong support of the global resource platform built by international development, the company has successfully cultivated three core businesses:

Industrial automation series products

Industrial robot series products

Industrial digital series products

As the first company in China to independently develop AC servo systems, industrial automation product line includes a full range of AC servo systems, frequency converters, PLC, touch screen, vision products and motion control systems, as well as motion control and robot integrated intelligent unit products with Trio control system as the core. To provide customers with personalized automation solutions from single axis - single machine - unit;

Industrial robot product line under the support of the company's independent core components has been ultra-rapid development, the product has formed a six-axis robot, the load range covers 3kg-600kg, more than 54 kinds of complete specification series, in the new energy, welding, metal processing, 3C electronics, construction machinery and other subsectors have a head customer and a large market share. In 2020, it was named by Forbes as the "2020 Forbes China's Most Innovative Enterprises List Industrial robot Enterprises".

FAQ

1.Who are We?

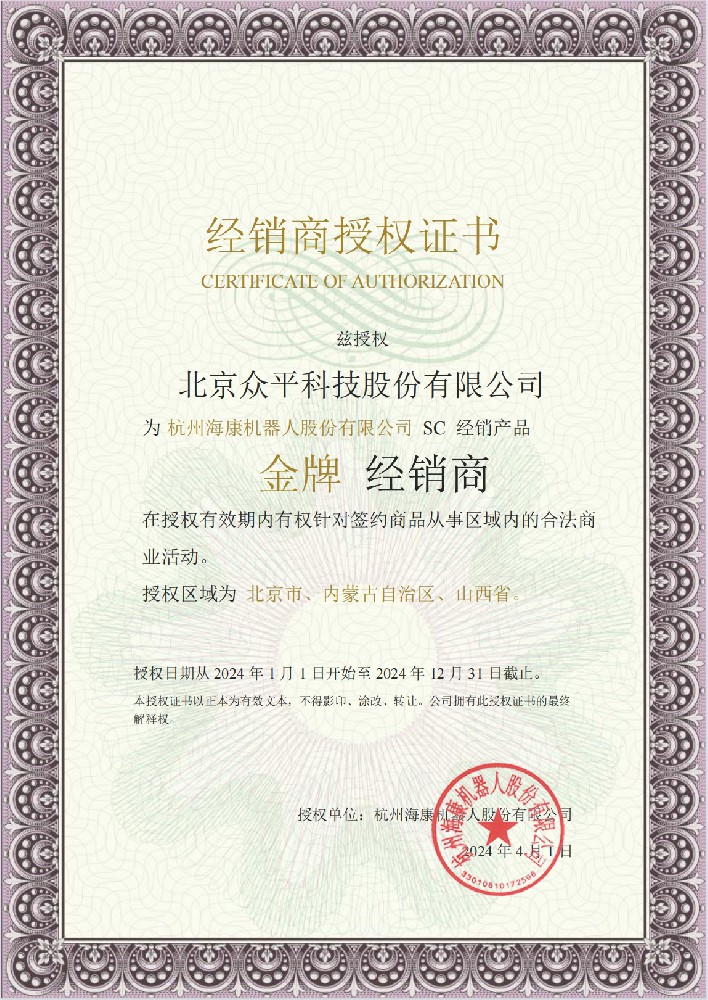

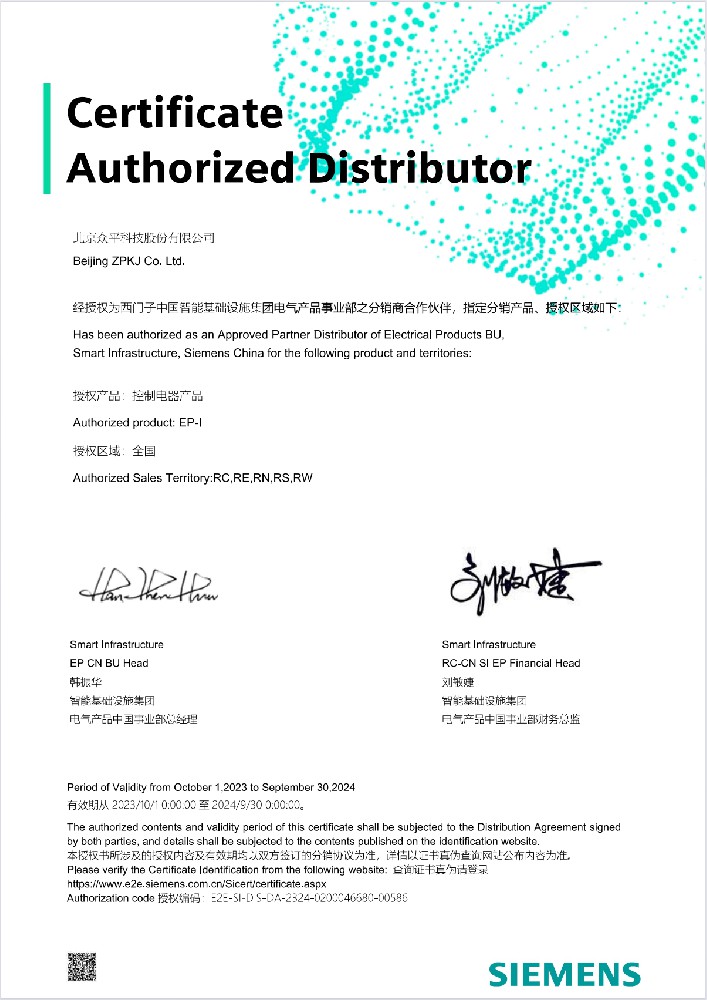

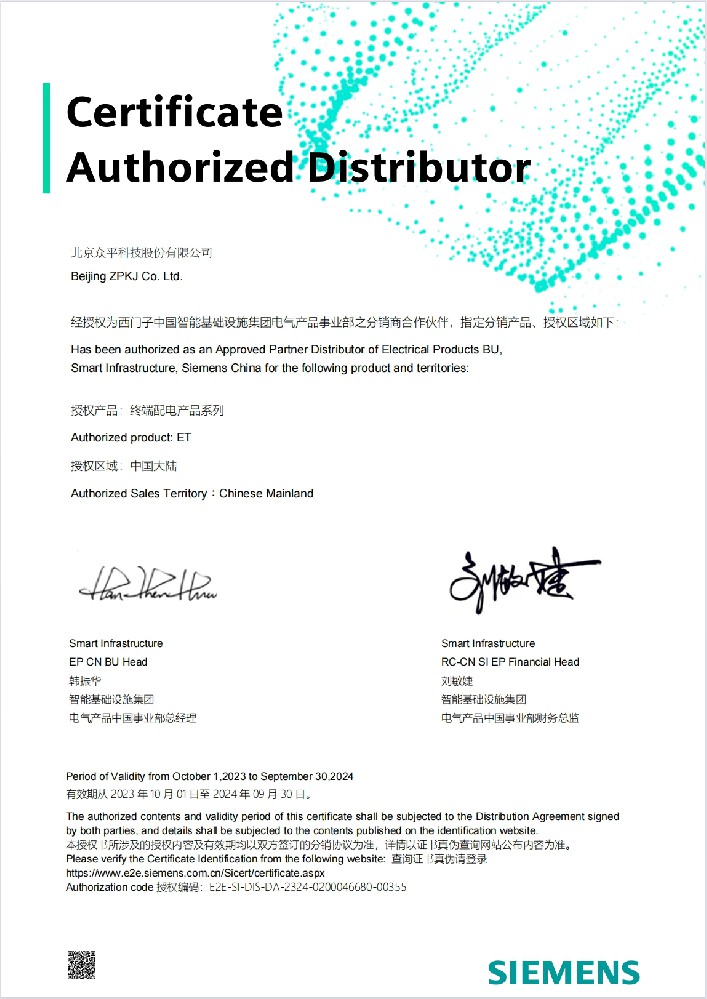

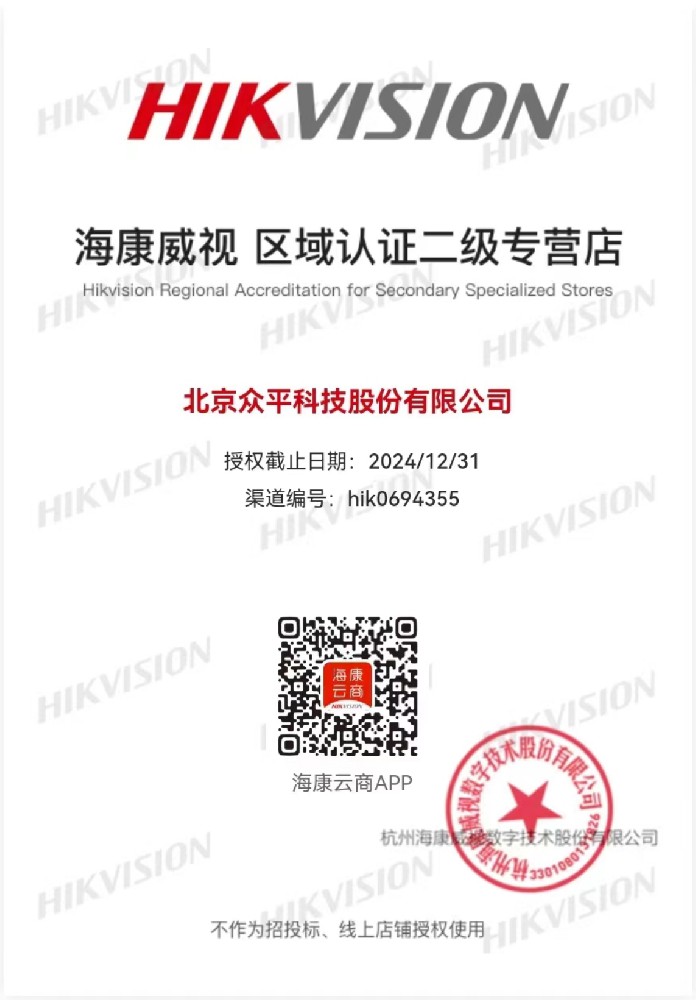

Beijing Zhongping Technology Co., LTD., is a one-stop integrated service provider of intelligent manufacturing, belongs to the Gong Doctor Group, is a scientific research, design, marketing, technical services, industrial Internet, international import and export services as one of the science and technology companies.

2.What can you buy from us?

PLC, inverter, human-machine interface, hydraulic products, low-voltage power distribution, industrial robots and core components

3.Is the item in stock or need to be purchased from another supplier?

We have a large inventory of goods and have our own warehouse.

4.What advantages do we have over other suppliers?

Our company has a large amount of inventory and a number of warehouses, but also in the country's important industrial provinces and cities with offices and a number of overseas service points. To provide you with intelligent manufacturing one-stop comprehensive services, save efforts, labor and cost.

5.Can you provide 100% new original authentic products?

We only sell new original genuine, no renovation, no fake, only for the original factory original!

6.How long is the delivery time?

If there is a stock, it will take 2-3 working days to ship, if the quantity is large, it will take 5-7 working days after receiving the payment, if it is not a conventional model, it will take some time, we will inform you of the specific delivery time.

7.Is there technical support available?

Of course, we have a professional technical team that can help you solve technical problems.

8.How do we guarantee quality?

We have three processes to control the quality of goods.

1). Our engineers will inspect the production and quality control in the factory regularly.

2) Incoming materials shall be inspected by experienced purchasing engineers before they can be stored.

3). At least 2 people in the logistics department cross-check the goods to be sent before delivery.

9.Can you guarantee the safe and reliable delivery of your products?

Yes, we strictly adopt the international standard packing. We also use special packaging for dangerous goods, and refrigerated shipping for items with temperature requirements. Special item packaging and general cargo standard packaging requirements may incur additional costs.

10.How about the freight?

The cost depends on how you choose to get the goods. Express is usually the fastest but also the most expensive way. Sea freight is the best solution for large quantities of goods. The exact shipping cost depends on the purchase amount、quantity and weight of your order. Please feel free to contact us for more information.

010-64225983

010-64225983 +8613811814778

+8613811814778 info@zhongpingtech.com

info@zhongpingtech.com Building 26, Liyuan Community, Chaoyang District, Beijing, China

Building 26, Liyuan Community, Chaoyang District, Beijing, China